English

English

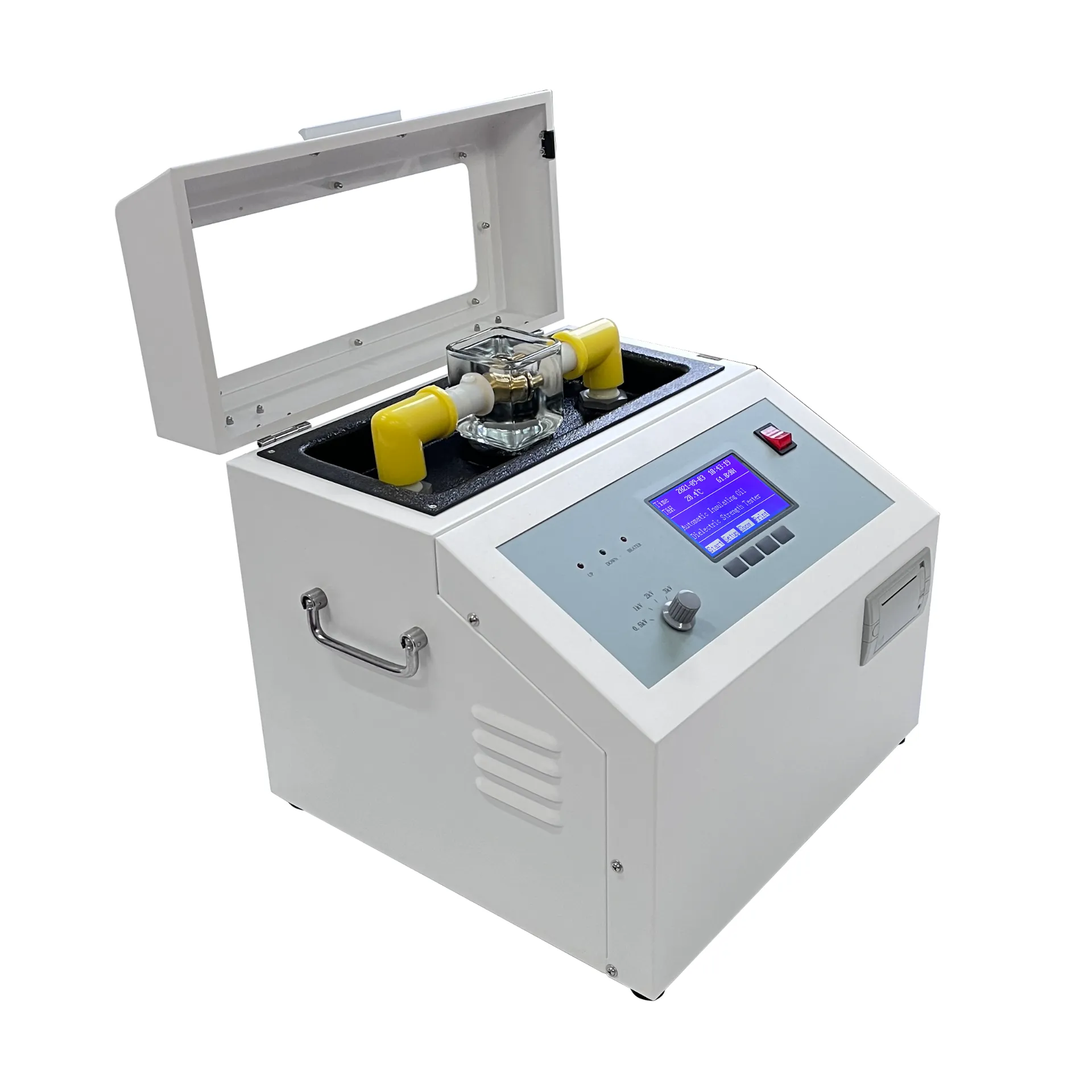

ac dc hipot tester

Understanding AC/DC Hipot Testers Ensuring Electrical Safety

AC/DC hipot testers, also known as dielectric strength testers, play a crucial role in the field of electrical safety. These sophisticated devices are designed to evaluate the insulation properties of electrical equipment by applying high voltage to the system and measuring its ability to withstand this stress. The term “hipot” derives from “high potential,” reflecting the high voltage that these testers use during operations.

Understanding AC/DC Hipot Testers Ensuring Electrical Safety

Hipot testers can produce both alternating current (AC) and direct current (DC) high voltage outputs, and the choice between the two typically depends on the specific requirements of the testing procedure. AC hipot testing is often used for testing insulation in devices where capacitive loading is significant. On the other hand, DC testing is effective for identifying weak spots in the insulation, as it can penetrate insulation materials more effectively than AC.

ac dc hipot tester

The testing process with a hipot tester is relatively straightforward. The device is connected to the equipment to be tested, and a predetermined high voltage is applied across the insulation barrier. The tester monitors the current that flows through the insulation. If the insulation is sound, the current remains within acceptable limits. However, if the insulation is compromised, excessive current flow may indicate a failure, signaling the need for further investigation or remediation before the device can be deemed safe for use.

Using an AC/DC hipot tester is not only a good practice for manufacturers but also a regulatory requirement in many industries. Compliance with safety standards set by organizations like IEC, UL, or CSA requires thorough testing of electrical equipment, ensuring that it meets specific insulation resistance levels and dielectric strength requirements.

Furthermore, regular calibration and maintenance of hipot testers are essential to ensure accuracy and reliability. This can involve procedures such as verifying the output voltage and current levels, checking for operational defects, and performing routine checks with test equipment. By maintaining these devices, organizations can avoid the risk of false readings that could potentially jeopardize safety.

In conclusion, AC/DC hipot testers are vital tools in the realm of electrical safety, providing essential evaluations of insulation integrity. By subjecting electrical apparatus to high-voltage testing, manufacturers and safety inspectors can ensure that these devices are safe for public usage. Consequently, the use of these testers is not only prudent but essential to advancing electrical safety standards across various industries. As technology continues to evolve, so will the methods and technologies used in hipot testing, reinforcing the importance of continuous innovation in ensuring electrical safety.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024