TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 05, 2025 03:20

Back to list

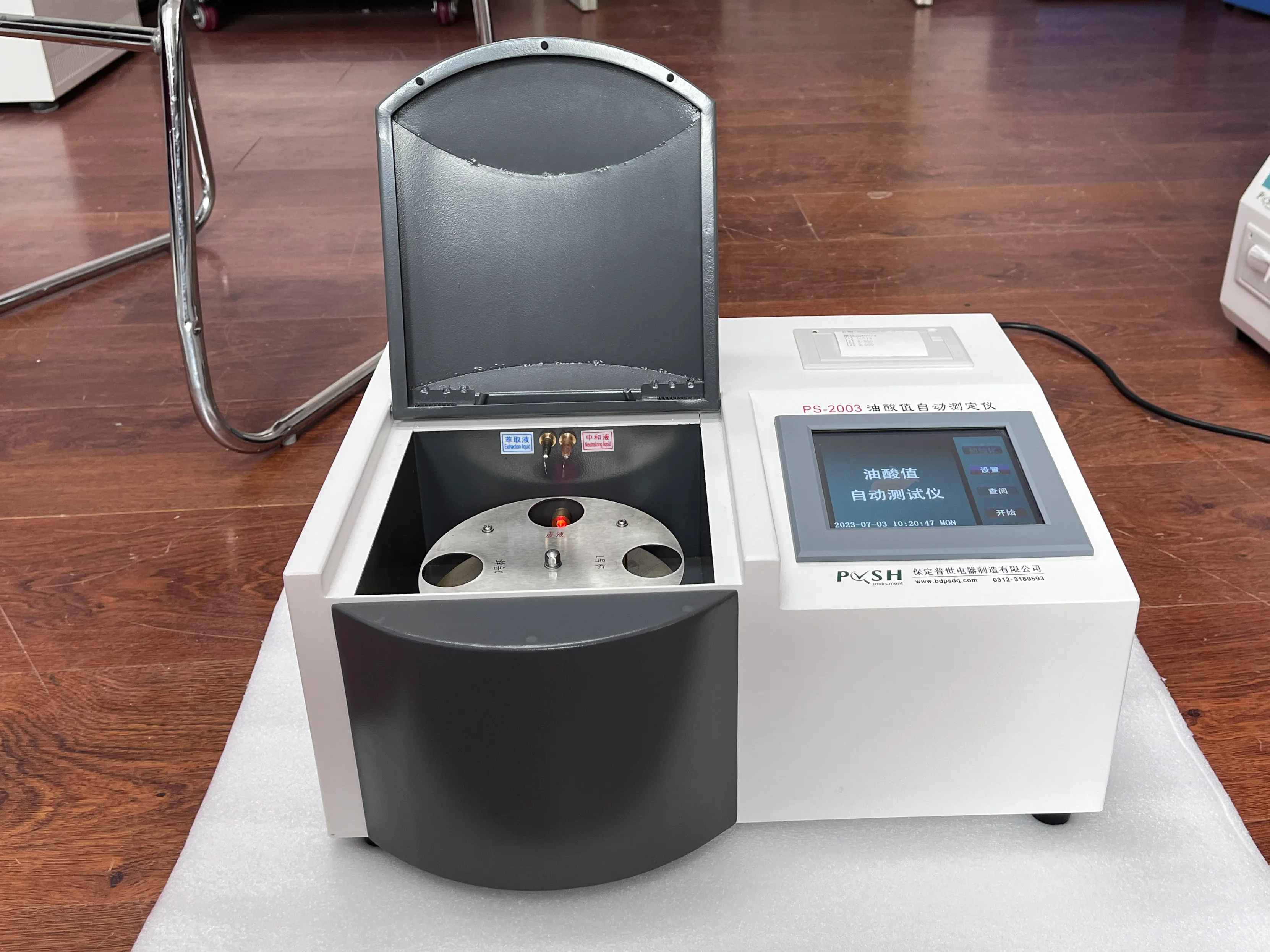

acidity test on transformer oil

Acidity levels in transformer oil are a critical determinant of transformer health and longevity, serving as a barometer for the condition of the insulating fluid and, by extension, the entire transformer system. Conducting an acidity test on transformer oil offers invaluable insights into the chemical stability of the oil and detects internal faults that might compromise the transformer’s operation. This article delves into why regular acidity testing is imperative, the process involved, and the interpretation of results.

Interpretation of acidity test results is a highly specialized task. For a transformer oil expert, assessing the TAN values involves comparing them against baseline data and industry standards. A TAN value up to 0.2 mg KOH/g is generally considered acceptable. Values exceeding this threshold suggest the imminent need for oil treatment processes, such as re-refining or complete replacement. In extreme cases, they may entail immediate transformer shutdown to prevent catastrophic failures. Trustworthy assessment of acidity levels additionally necessitates considering external environmental factors, such as moisture content, temperature fluctuations, and load cycles. Each of these can further influence the oil’s aging process, thus affecting acidity levels. Consequently, experts often correlate acidity levels with other tests, like Interfacial Tension (IFT) and Dissolved Gas Analysis (DGA), to paint a comprehensive picture of the oil’s condition and foresee potential issues. The trustworthiness of acidity testing is bolstered by employing standardized methods as prescribed by international bodies like ASTM (American Society for Testing and Materials) or IEC (International Electrotechnical Commission). Compliance with these standards ensures reliability and comparability of results, which is crucial for making informed maintenance decisions. In conclusion, regular acidity tests on transformer oil are non-negotiable for maintaining the functionality and safety of transformers. They provide critical insights into the chemical integrity of transformer oil, facilitating preemptive maintenance strategies. With their potential to forecast issues before they manifest into disastrous failures, these tests are a cornerstone of efficient transformer fleet management. Engaging with expert analysts and adhering to global testing protocols enhances the fidelity of test outcomes, ensuring that transformers operate at optimal performance over an extended lifespan.

Interpretation of acidity test results is a highly specialized task. For a transformer oil expert, assessing the TAN values involves comparing them against baseline data and industry standards. A TAN value up to 0.2 mg KOH/g is generally considered acceptable. Values exceeding this threshold suggest the imminent need for oil treatment processes, such as re-refining or complete replacement. In extreme cases, they may entail immediate transformer shutdown to prevent catastrophic failures. Trustworthy assessment of acidity levels additionally necessitates considering external environmental factors, such as moisture content, temperature fluctuations, and load cycles. Each of these can further influence the oil’s aging process, thus affecting acidity levels. Consequently, experts often correlate acidity levels with other tests, like Interfacial Tension (IFT) and Dissolved Gas Analysis (DGA), to paint a comprehensive picture of the oil’s condition and foresee potential issues. The trustworthiness of acidity testing is bolstered by employing standardized methods as prescribed by international bodies like ASTM (American Society for Testing and Materials) or IEC (International Electrotechnical Commission). Compliance with these standards ensures reliability and comparability of results, which is crucial for making informed maintenance decisions. In conclusion, regular acidity tests on transformer oil are non-negotiable for maintaining the functionality and safety of transformers. They provide critical insights into the chemical integrity of transformer oil, facilitating preemptive maintenance strategies. With their potential to forecast issues before they manifest into disastrous failures, these tests are a cornerstone of efficient transformer fleet management. Engaging with expert analysts and adhering to global testing protocols enhances the fidelity of test outcomes, ensuring that transformers operate at optimal performance over an extended lifespan.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024