English

English

ac withstand test

Understanding the AC Withstand Test Importance and Applications

In today’s rapidly advancing technological landscape, the reliability and safety of electrical and electronic components are paramount. Among the various testing procedures that ensure these standards are met, the AC withstand test plays a significant role. This article explores the concept, methodology, and importance of the AC withstand test, particularly in the realm of electrical safety and compliance.

The AC withstand test, commonly referred to as the voltage withstand test or insulation resistance test, is designed to verify the integrity and safety of electrical insulation in equipment and components. This procedure evaluates whether the insulation can withstand high voltage without breaking down, thereby preventing electrical failures that could lead to accidents or equipment damage.

Methodology of the AC Withstand Test

The testing process typically involves applying a predetermined AC voltage to the electrical device under test (DUT) for a specified duration. This voltage is significantly higher than the normal operating voltage, allowing engineers to assess the robustness of the insulation. The standard voltage level may vary depending on the type and application of the device, but it is essential to adhere to industry norms and safety regulations.

During the test, any dielectric failure or breakdown in the insulation can be detected by monitoring leakage currents. If the insulation withstands the test, it implies that it can effectively protect against regular operational voltages and occasional surges. Conversely, a failure indicates that the insulation may be inadequate, necessitating further investigation or redesign.

Importance of the AC Withstand Test

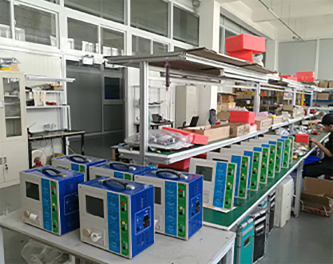

ac withstand test

1. Safety Compliance The primary purpose of the AC withstand test is to ensure that electrical devices comply with safety standards established by regulatory bodies like UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission). Compliance not only protects end-users but also ensures manufacturers avoid legal liabilities.

2. Preventive Maintenance Regularly conducting AC withstand tests can serve as an essential part of maintenance programs. By identifying weak insulation early, operators can take corrective actions before failures occur, reducing downtime and costly repairs.

3. Quality Assurance For manufacturers, implementing AC withstand testing as a quality control measure helps maintain high production standards. This not only increases customer confidence but also enhances the overall reputation of the brand in a competitive marketplace.

4. Lifecycle Assessment As equipment ages, its insulation may deteriorate due to factors such as environmental conditions or mechanical stress. The AC withstand test can provide valuable insights into the lifecycle and longevity of electrical components, aiding in effective asset management.

Conclusion

The AC withstand test is a critical methodology for ensuring the safety and reliability of electrical devices. By rigorously assessing the insulation quality, manufacturers and operators can minimize risks, enhance equipment performance, and comply with necessary safety regulations. As technology evolves and electrical systems become more complex, the relevance and importance of thorough testing procedures like the AC withstand test will only continue to grow, safeguarding both users and the integrity of electrical infrastructure.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024