English

English

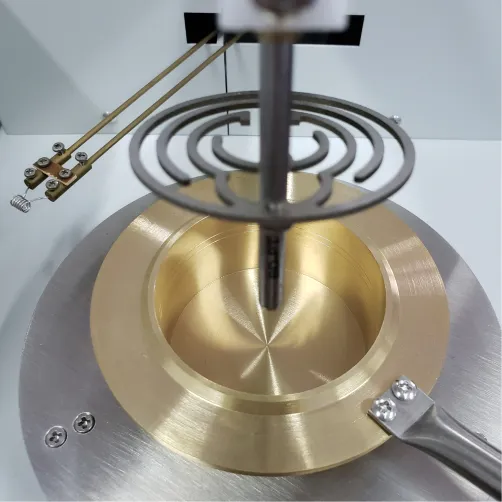

Advanced Oil Moisture Testing Equipment for Accurate Detection and Analysis in Various Applications

Understanding Oil Moisture Testers Importance and Applications

In various industries, particularly in food processing, agriculture, and oil extraction, understanding the moisture content in oils is crucial for maintaining quality, ensuring safety, and optimizing production processes. This is where oil moisture testers come into play. These specialized devices measure the moisture levels in oils, providing essential data that can significantly influence product quality and operational efficiency.

What is an Oil Moisture Tester?

An oil moisture tester is an analytical instrument designed to quantify the amount of water contained in oil. The importance of monitoring moisture levels cannot be understated; excessive moisture in oil can lead to spoilage, degradation, and a range of quality issues that could compromise the end product. For instance, in the food industry, oils that contain too much moisture could lead to rancidity, adversely affecting flavor and safety. In industrial applications, moisture in lubricating oils can result in increased wear and tear on machinery, ultimately leading to more frequent maintenance and repairs.

How Does It Work?

Oil moisture testers operate based on various principles, including electrical resistance, capacitance measurement, and infrared analysis. For example, the electrical resistance method measures the conductivity of the oil, which increases with the presence of water. Capacitance measurement utilizes the change in dielectric constant caused by the presence of moisture in the oil. Infrared spectroscopy, on the other hand, allows for a more precise analysis by measuring absorption spectra of different components in the oil, giving a clear indication of moisture levels.

Importance of Regular Testing

oil moisture tester

Regular testing of oil moisture content is vital for multiple reasons. First, it helps ensure product quality and safety. In sectors like food processing, maintaining the appropriate moisture level helps prevent microbial growth and extends the shelf life of the product. For industrial lubricants, monitoring moisture is crucial to avoid the detrimental effects of water on lubricating properties and to prevent corrosion of machinery.

Additionally, regular moisture testing is an integral part of quality control processes in production lines. By using oil moisture testers, manufacturers can identify potential issues early, allowing for timely interventions. This proactive approach can save on costs associated with product recalls, reworks, and unscheduled machine downtimes.

Applications Across Industries

The applications of oil moisture testers span a wide range of industries. In the food and beverage sector, they are used to ensure the quality of oils used in cooking and food preservation. In the automotive and manufacturing industries, they are employed to monitor lubricating oils in machinery to ensure optimal performance and longevity. Agriculture also benefits from oil moisture testing, especially in the extraction of essential oils from plants, which requires precise moisture control to ensure the quality of the extract.

Moreover, in biofuels, monitoring moisture content is essential to optimize combustion efficiency and prevent damage to engines and equipment. As the demand for sustainable energy sources rises, oil moisture testers play a significant role in improving production processes and ensuring quality standards.

Conclusion

In conclusion, oil moisture testers are indispensable tools across various sectors, enhancing quality control and operational efficiency. By providing accurate measurements of moisture levels in oils, they help maintain product integrity and prevent costly errors. As industries continue to evolve and focus on quality and sustainability, the role of oil moisture testers will only become more significant in ensuring that products meet required standards and customer expectations. Understanding and implementing moisture testing can lead to smarter, more efficient production and an overall enhancement in product quality.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024