English

English

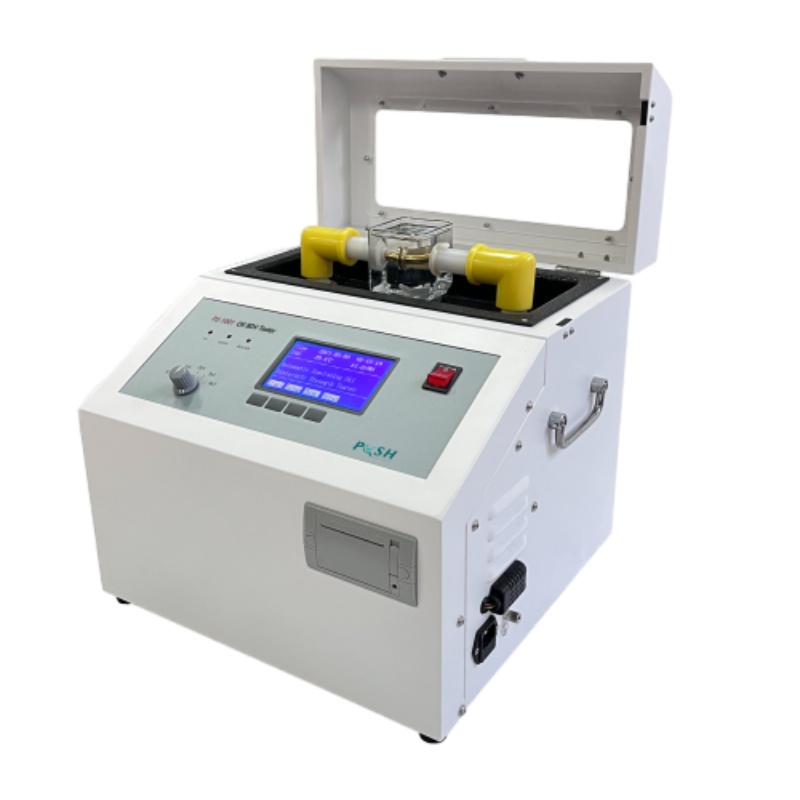

Advanced Testing Equipment for Tan Delta Measurements in Electrical Insulation Systems

Understanding Tan Delta Test Equipment An Essential Tool for Insulation Testing

The integrity of electrical insulation is crucial for the safe and reliable operation of high-voltage equipment. One of the most effective methods for assessing insulation quality is the Tan Delta test, a technique that measures the dissipation factor or power factor of insulating materials. Tan Delta test equipment plays a pivotal role in ensuring the reliability and safety of insulating systems in various electrical applications.

What is the Tan Delta Test?

The Tan Delta test, also known as the loss angle test, is a diagnostic technique used to evaluate the condition of insulation in electrical components such as transformers, cables, and switchgear. The test determines the ratio of the resistive component to the reactive component of the insulation's impedance at a specific voltage and frequency. Specifically, it measures the dielectric loss (tan delta) of the insulation, providing valuable insights into its health and potential issues.

The principle behind the Tan Delta test lies in measuring the phase angle between the current and voltage in an electrical system. The tan delta value represents the amount of energy lost as heat due to the dielectric materials within the insulation system. A higher tan delta value indicates higher losses, which may suggest deterioration of the insulating material or the presence of moisture, contamination, or other impairments.

Importance of Tan Delta Testing

Regular Tan Delta testing is critical for predictive maintenance strategies in electrical utilities and industries. By identifying insulation problems before they escalate, organizations can prevent costly failures and downtime associated with insulation breakdown. This proactive approach not only enhances equipment reliability but also extends its operational lifespan.

In addition to maintenance, Tan Delta testing is essential for quality control during the manufacturing process and commissioning of new equipment. It helps manufacturers ensure that the insulation materials meet regulatory standards and performance specifications, thus guaranteeing the safety and efficiency of the equipment.

Components of Tan Delta Test Equipment

Tan Delta test equipment typically consists of several key components

tan delta test equipment

1. Power Supply A high-voltage AC source is often required to energize the insulating material being tested. This allows for the evaluation of the insulation's behavior under operational conditions.

2. Measuring Device This is the core of the Tan Delta test equipment. It measures the voltage and current, calculating the tan delta value based on the phase difference between them.

3. Measurement Interface Modern Tan Delta testers come equipped with digital displays and user-friendly interfaces, enabling technicians to easily interpret test results and generate reports.

4. Safety Features Given the high voltages involved, safety is paramount. Good quality Tan Delta test equipment incorporates protective measures to safeguard operators and equipment.

Best Practices for Tan Delta Testing

For accurate results, it is essential to follow best practices during the Tan Delta testing process

- Preparation Ensure the equipment is properly calibrated and that the testing environment is free of contaminants such as moisture and dust. - Sampling Take multiple readings at various voltage levels to obtain a comprehensive understanding of the insulation condition. - Analysis Compare measured tan delta values against established benchmarks and historical data to identify trends and potential issues.

Conclusion

Tan Delta test equipment is a crucial asset in the field of electrical engineering and maintenance, providing valuable insights into the health of insulating systems. By regularly employing this testing method, utilities and industries can enhance equipment performance, increase operational reliability, and significantly reduce the risk of unexpected failures. As technology advances, the capabilities of Tan Delta testers continue to evolve, making them an indispensable tool for effective insulation management.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024