English

English

Advanced Testing Setup for Oil Pump Performance Evaluation and Efficiency Optimization Solutions

Understanding the Oil Pump Test Bench A Key Tool in Hydraulic Testing

In the realm of hydraulic systems, especially in industries related to oil and gas, the oil pump test bench is an indispensable tool. This specialized equipment is designed to evaluate the performance of various types of oil pumps under controlled conditions. By creating a standardized environment for testing, engineers and technicians can gather critical data regarding the efficiency, durability, and overall performance of pumps, ensuring that they meet industry standards and operational requirements.

What is an Oil Pump Test Bench?

An oil pump test bench is a setup that simulates the operational conditions of an oil pump. It typically includes a variety of components such as flow meters, pressure gauges, temperature sensors, and control valves, all integrated into a testing environment where the oil pump can operate. The bench allows for the precise measurement of flow rates, pressure drops, and temperature variations, providing a comprehensive view of the pump's performance characteristics.

The Importance of Testing

The primary purpose of the oil pump test bench is to ensure that pumps meet specified performance criteria before they are deployed in actual operational environments. In industries such as petroleum, marine, and manufacturing, the reliability and efficiency of pumps are critical. Any failure can lead to not only economic losses but also safety hazards. Therefore, rigorous testing allows engineers to identify any potential issues, such as cavitation, noise, vibration, and inefficient operation, which might otherwise go unnoticed.

Types of Tests Conducted

Various tests can be conducted using an oil pump test bench, including

1. Flow Tests Measuring the flow rate that the pump can provide at different pressures and speeds. This helps determine if the pump can meet the demands of its application.

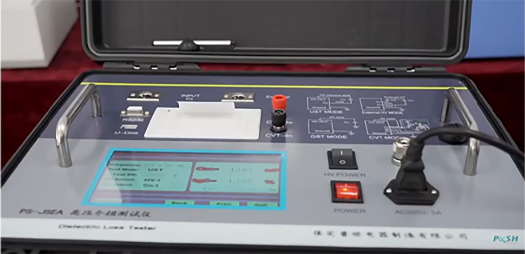

oil pump test bench

2. Pressure Tests Assessing the ability of the pump to maintain pressure under varying conditions. This is crucial for ensuring that the pump can handle the operational stresses it will encounter.

3. Efficiency Tests Evaluating the hydraulic and volumetric efficiency of the pump. A pump that operates with high efficiency conserves energy and reduces operational costs.

4. Durability Tests Running the pump under extreme conditions (such as high temperatures or pressures) for prolonged periods to assess its durability and longevity.

Benefits of Using an Oil Pump Test Bench

By employing an oil pump test bench, companies can enjoy multiple benefits. Firstly, it enhances the quality control process. With a systematic approach to testing, manufacturers can identify defects before products reach the market, thus minimizing warranty claims and enhancing customer satisfaction.

Secondly, it aids in research and development. Engineers can experiment with different pump designs and configurations, gaining insights that drive innovation. This ability to test prototypes in a controlled setting accelerates the design process and brings better products to the market faster.

Lastly, the data obtained from these tests contributes to maintaining compliance with industry standards and regulations. In sectors where safety and reliability are paramount, such compliance is not negotiable.

Conclusion

In conclusion, the oil pump test bench plays a crucial role in ensuring the performance and reliability of oil pumps across various industries. As technology advances and the demands for efficiency and safety increase, the importance of this testing equipment will only grow. Investing in proper testing methodologies not only protects companies from potential hazards but also reinforces their reputation in the marketplace as providers of high-quality, reliable products. Through diligent testing and development, the oil and gas industry can continue to thrive while maintaining the highest standards of safety and efficiency.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024