TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 05, 2025 04:10

Back to list

applied voltage test for power transformer

The applied voltage test for power transformers stands as a crucial procedure that ensures the reliability and safety of transformers used in electric power systems. This test is one part of a comprehensive testing regime that guarantees transformers can handle the specified system voltages under various operating conditions. Understanding the applied voltage test, its procedures, and its significance is essential for professionals involved in the production, maintenance, and operation of power transformers.

Beyond confirming the robustness of the transformer’s insulation system, the applied voltage test serves several other purposes. It helps identify manufacturing defects, that might not have been apparent during visual inspections or preliminary testing. Catching issues at this stage can prevent costly failures and service interruptions later when the transformer is in operation. Moreover, this test is also a valuable tool during scheduled maintenance, assessing the health of the transformer and determining if ageing components need refurbishment or replacement. Expert knowledge is fundamental when conducting applied voltage tests. Technicians must be adept in understanding the nuances of different transformer designs and specifications. Extensive training equips them with the skills to interpret test results accurately and make informed decisions about the transformer's condition and suitability for service. Additionally, adherence to safety procedures is non-negotiable, given the high voltages involved and the potential risks of electrical shock or fires. From a trustworthiness perspective, transformers that have undergone successful applied voltage testing provide assurance of safety and reliability to utilities and consumers. Energy providers can confidently supply consistent power, knowing their infrastructure can handle the demands placed upon it by modern electricity consumption patterns. Trust in the testing process is fortified by compliance with international standards, enforced by regulatory bodies that mandate these rigorous assessments. In conclusion, the applied voltage test for power transformers represents a vital component in the lifecycle management of electrical power systems, underscoring the importance of rigorous testing in ensuring operational excellence. Its comprehensive evaluation of a transformer's insulation capabilities preserves the integrity of power networks and safeguards against potential failures. Emphasizing professional expertise, stringent safety protocols, and a steadfast commitment to industry standards underscores the importance of this testing regime in maintaining the reliability of one of our most critical infrastructure elements.

Beyond confirming the robustness of the transformer’s insulation system, the applied voltage test serves several other purposes. It helps identify manufacturing defects, that might not have been apparent during visual inspections or preliminary testing. Catching issues at this stage can prevent costly failures and service interruptions later when the transformer is in operation. Moreover, this test is also a valuable tool during scheduled maintenance, assessing the health of the transformer and determining if ageing components need refurbishment or replacement. Expert knowledge is fundamental when conducting applied voltage tests. Technicians must be adept in understanding the nuances of different transformer designs and specifications. Extensive training equips them with the skills to interpret test results accurately and make informed decisions about the transformer's condition and suitability for service. Additionally, adherence to safety procedures is non-negotiable, given the high voltages involved and the potential risks of electrical shock or fires. From a trustworthiness perspective, transformers that have undergone successful applied voltage testing provide assurance of safety and reliability to utilities and consumers. Energy providers can confidently supply consistent power, knowing their infrastructure can handle the demands placed upon it by modern electricity consumption patterns. Trust in the testing process is fortified by compliance with international standards, enforced by regulatory bodies that mandate these rigorous assessments. In conclusion, the applied voltage test for power transformers represents a vital component in the lifecycle management of electrical power systems, underscoring the importance of rigorous testing in ensuring operational excellence. Its comprehensive evaluation of a transformer's insulation capabilities preserves the integrity of power networks and safeguards against potential failures. Emphasizing professional expertise, stringent safety protocols, and a steadfast commitment to industry standards underscores the importance of this testing regime in maintaining the reliability of one of our most critical infrastructure elements.

Next:

Latest news

-

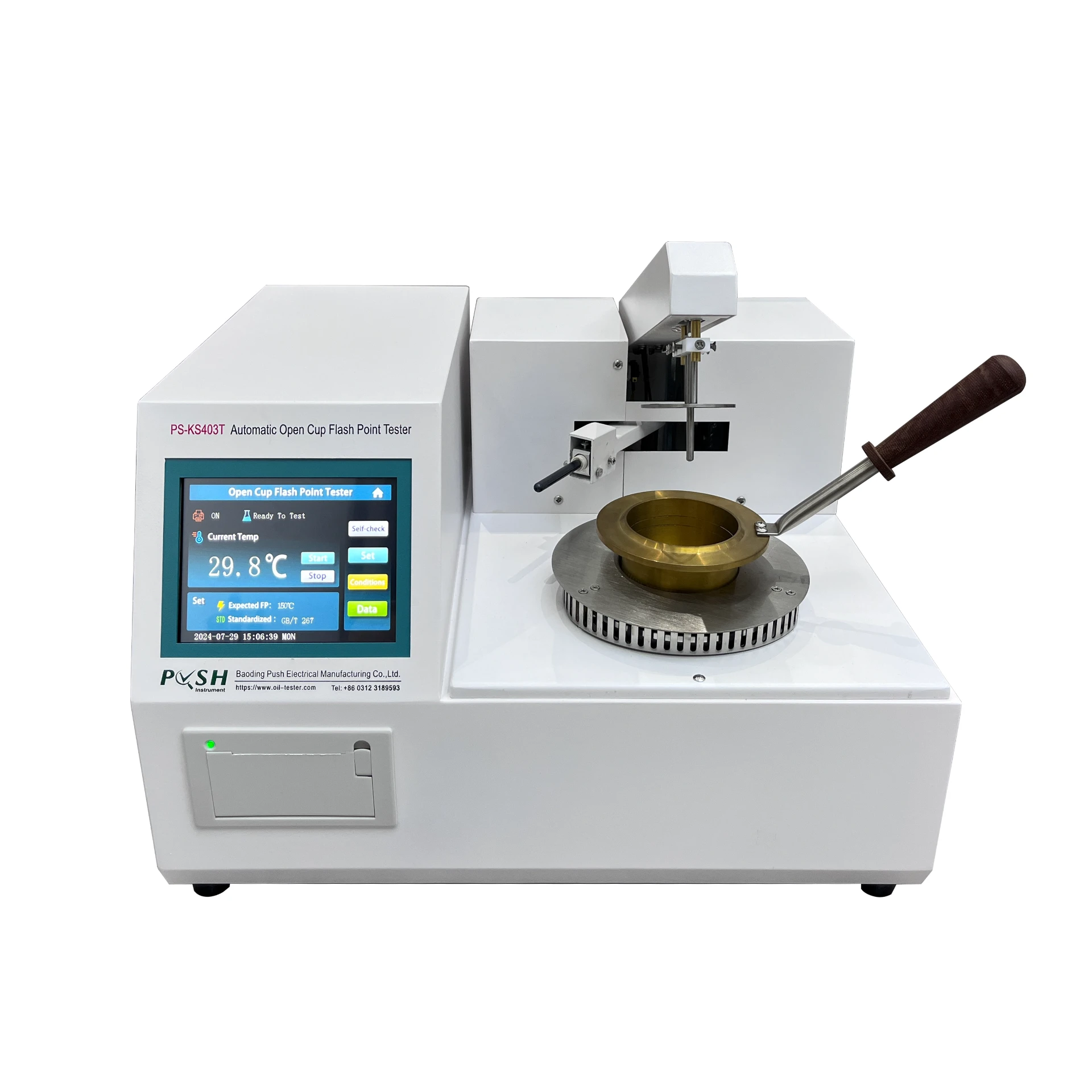

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024