English

English

Assessing Transformer Integrity Through Polarization Index Testing in Electrical Systems

Understanding Polarization Index Testing for Transformers

Polarization Index (PI) testing is an essential diagnostic tool used in the electrical industry, particularly for assessing the insulation condition of transformers. As transformers play a critical role in electrical power distribution and transmission, ensuring their reliability and safety is paramount. PI testing offers a straightforward method to evaluate insulation integrity, providing insights into potential problems before they lead to significant failures.

What is Polarization Index Testing?

The Polarization Index is defined as the ratio of the insulation resistance measured after a specific polarization time (typically 10 minutes) to the resistance measured immediately after applying a voltage (1 minute). This testing method relies on the principle that over time, the dielectric material of the transformer insulation becomes polarized. As a result, the insulation resistance rises as more time is allowed for the charges to stabilize, leading to a clearer understanding of the insulation’s condition.

The formula for calculating the Polarization Index is

\[ PI = \frac{R_{10}}{R_{1}} \]

where \( R_{10} \) is the insulation resistance at 10 minutes, and \( R_{1} \) is the insulation resistance at 1 minute. A higher PI value typically indicates better insulation quality.

Importance of PI Testing

1. Predictive Maintenance PI testing helps in developing a predictive maintenance strategy by identifying insulation problems early. Transformers operate under high electrical stress, making them susceptible to insulation breakdown. Regular PI measurements can indicate trends in insulation health, helping maintenance teams schedule interventions before failures occur.

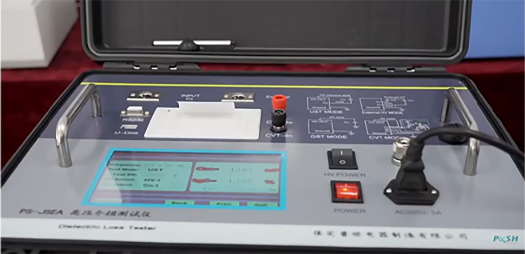

polarization index testing transformer

2. Assessment of Aging Insulation Over time, the insulation material can degrade due to thermal, electrical, and environmental factors. The PI test can help in assessing the degree of insulation aging, giving engineers important data to make informed decisions regarding repair or replacement.

3. Identification of Moisture Intrusion One of the leading causes of insulation failure in transformers is moisture content. A significant drop in the PI value may suggest the presence of moisture, which can deteriorate the dielectric properties of the insulation. Early identification allows for corrective actions, such as drying the insulation or replacing it if necessary.

4. Industry Standards Compliance Various industry standards and guidelines, such as IEEE and IEC, recommend PI testing as part of a comprehensive maintenance program for insulating systems. Compliance with these standards not only ensures the safety and reliability of electrical equipment but also protects the investment made in infrastructure.

Understanding PI Values

Interpreting the results of a PI test involves understanding the threshold values. Generally, a PI value greater than 1.0 is considered acceptable, with values above 2.0 indicating good insulation quality. When values drop below 1.0, it signals potential insulation problems that require further investigation.

However, it’s important to note that PI values should not be viewed in isolation. They should be considered alongside other diagnostic tests, such as dielectric breakdown voltage tests and thermal imaging, to provide a comprehensive picture of transformer health.

Conclusion

Polarization Index testing is a vital process in the maintenance and monitoring of transformer insulation systems. It serves as an early warning system for potential failures and assists in strategic planning for maintenance activities. By understanding and applying PI testing, electrical engineers can enhance the reliability of transformers, ultimately contributing to the efficiency and safety of electrical power distribution systems. Regular testing, coupled with a proactive approach to maintenance, ensures that transformers can operate effectively throughout their service life.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024