English

English

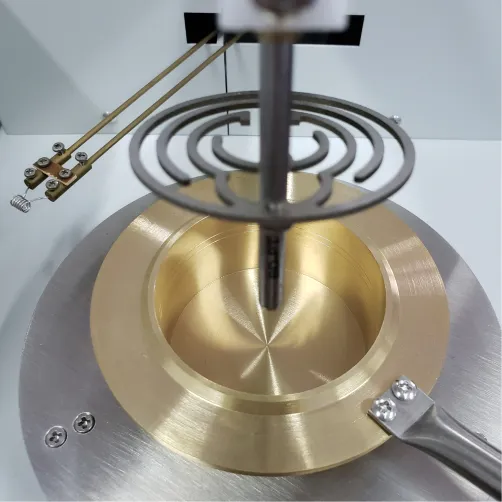

automated flash point tester

The Importance of Automated Flash Point Testers in Industry

In industrial applications, understanding the flammability of liquids is crucial for ensuring safety and compliance with regulations. The flash point, which is the lowest temperature at which vapors of a volatile material can ignite in air, is a key parameter when assessing the hazards associated with handling and storing chemical substances. To streamline this process, automated flash point testers have emerged as an essential tool in laboratories and industrial settings.

Automated flash point testers are sophisticated devices designed to measure the flash point of various liquids efficiently and accurately. Unlike traditional methods that often require manual operation and extensive time, automated testing provides consistent results with minimal human intervention. This not only reduces the likelihood of human error but also increases throughput, allowing laboratories to conduct numerous tests in a shorter period.

One of the significant advantages of automated flash point testers is their ability to adhere to international testing standards, such as ASTM D7094 or ASTM D56. These standards ensure that the methods used for testing are reliable and acceptable across various industries. Automated devices are built to incorporate specific safety features, reducing the risk of accidents associated with handling flammable substances. For instance, these testers often include advanced ventilation systems and fail-safe mechanisms that protect operators from potential hazards while conducting tests.

automated flash point tester

Furthermore, automated flash point testers offer enhanced data management capabilities. Many models come equipped with software that not only records the test results but also provides statistical analysis and reporting features. This is especially beneficial for industries where compliance with regulatory agencies is mandatory. Being able to generate precise reports quickly significantly eases the burden of audits and inspections.

In the petroleum, chemical manufacturing, and pharmaceuticals industries, understanding the flash point is vital for transportation and storage planning. Liquids with low flash points require special handling procedures and storage conditions to prevent accidental ignitions. By using automated flash point testers, companies can make informed decisions regarding material safety data sheets, shipping protocols, and emergency response strategies.

Moreover, the trend toward automation in testing processes aligns with broader industry movements toward digital transformation. The incorporation of automated flash point testers can lead to improved operational efficiency, lower labor costs, and higher safety standards. As industries continue to evolve, the demand for reliable and efficient testing technologies will only grow.

In conclusion, automated flash point testers are indispensable in numerous sectors due to their efficiency, accuracy, and safety features. As companies strive to maintain compliance with safety regulations and boost operational productivity, investing in these advanced testing solutions will undoubtedly contribute to safer working environments and effective risk management strategies. By leveraging technology in flash point testing, industries can better navigate the complexities of hazardous materials and prioritize safety in their operations.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024