TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 06, 2025 01:24

Back to list

breakdown voltage test of transformer oil pdf

Understanding the Breakdown Voltage Test of Transformer Oil

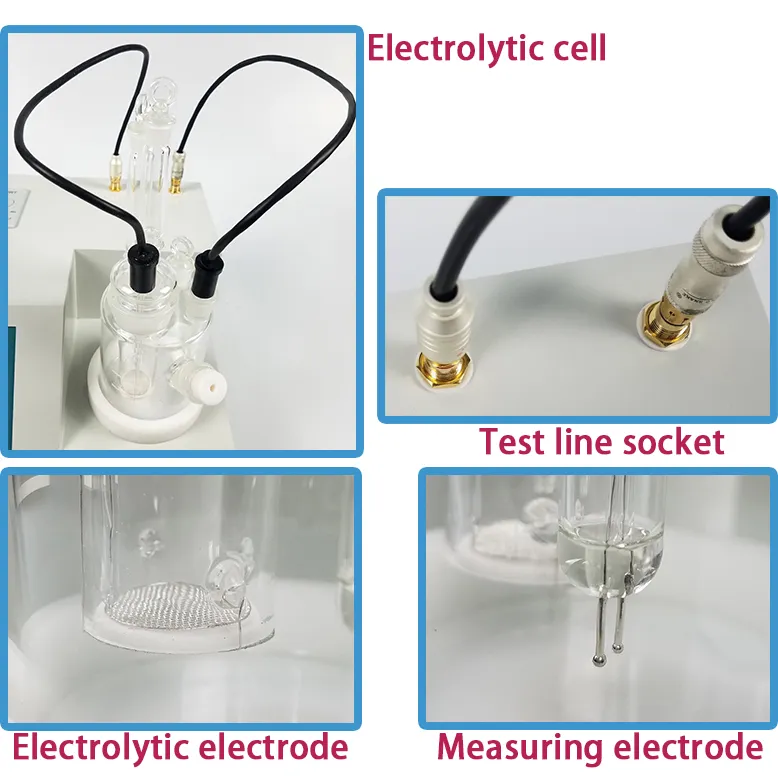

When conducting a breakdown voltage test, start by ensuring that both electrodes are clean and properly aligned. The oil sample should be free from bubbles, as these can cause premature breakdown and provide false results. Gradual increases in voltage should be applied, maintaining a steady rate until breakdown occurs. The readings obtained from the test are then compared against standard threshold values to determine oil quality. For electrical professionals, understanding test results is crucial. Results indicating low breakdown voltage typically point to the presence of moisture, conductive particles, or other contaminants. In such cases, filtration or purification processes like degassing and moisture removal may be required. Safety is a priority during the breakdown voltage test. Adhering to safety protocols minimizes the risk of accidents. Personnel should be trained, and appropriate safety gear such as insulated gloves and eye protection should be used when handling high-voltage testing equipment. For industries reliant on transformers, regular breakdown voltage testing is not merely routine but a cornerstone of holistic asset management. It reduces the risk of catastrophic failures, which can have severe operational and financial implications. The breakdown voltage test of transformer oil is not only a testament to the dedication to maintaining high performance standards but also an investment in the sustainability of electrical infrastructure. Professional insight into the complexities of testing and interpreting results ensures transformers remain robust components within global power grids. In conclusion, while the breakdown voltage test of transformer oil might appear specific and technical, its implications are broad and significant. By validating the dielectric integrity of transformer oil, this test helps maintain reliable and efficient power delivery, thereby contributing to overall electrical system efficacy. Such expertise underscores the indispensable nature of regular, meticulous testing in the lifespan of transformers.

When conducting a breakdown voltage test, start by ensuring that both electrodes are clean and properly aligned. The oil sample should be free from bubbles, as these can cause premature breakdown and provide false results. Gradual increases in voltage should be applied, maintaining a steady rate until breakdown occurs. The readings obtained from the test are then compared against standard threshold values to determine oil quality. For electrical professionals, understanding test results is crucial. Results indicating low breakdown voltage typically point to the presence of moisture, conductive particles, or other contaminants. In such cases, filtration or purification processes like degassing and moisture removal may be required. Safety is a priority during the breakdown voltage test. Adhering to safety protocols minimizes the risk of accidents. Personnel should be trained, and appropriate safety gear such as insulated gloves and eye protection should be used when handling high-voltage testing equipment. For industries reliant on transformers, regular breakdown voltage testing is not merely routine but a cornerstone of holistic asset management. It reduces the risk of catastrophic failures, which can have severe operational and financial implications. The breakdown voltage test of transformer oil is not only a testament to the dedication to maintaining high performance standards but also an investment in the sustainability of electrical infrastructure. Professional insight into the complexities of testing and interpreting results ensures transformers remain robust components within global power grids. In conclusion, while the breakdown voltage test of transformer oil might appear specific and technical, its implications are broad and significant. By validating the dielectric integrity of transformer oil, this test helps maintain reliable and efficient power delivery, thereby contributing to overall electrical system efficacy. Such expertise underscores the indispensable nature of regular, meticulous testing in the lifespan of transformers.

Previous:

Next:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024