English

English

bushing test in transformer

Bushing Test in Transformers An Essential Maintenance Procedure

Transformers are crucial components in electrical power systems, responsible for stepping up or stepping down voltage levels to ensure efficient power distribution. Among their many parts, the bushings play a vital role in providing electrical insulation and mechanical support. However, like all components, bushings can deteriorate over time due to environmental factors, electrical stress, and mechanical wear. Hence, performing a bushing test is essential to ensure the reliability and safety of transformers.

Bushing Test in Transformers An Essential Maintenance Procedure

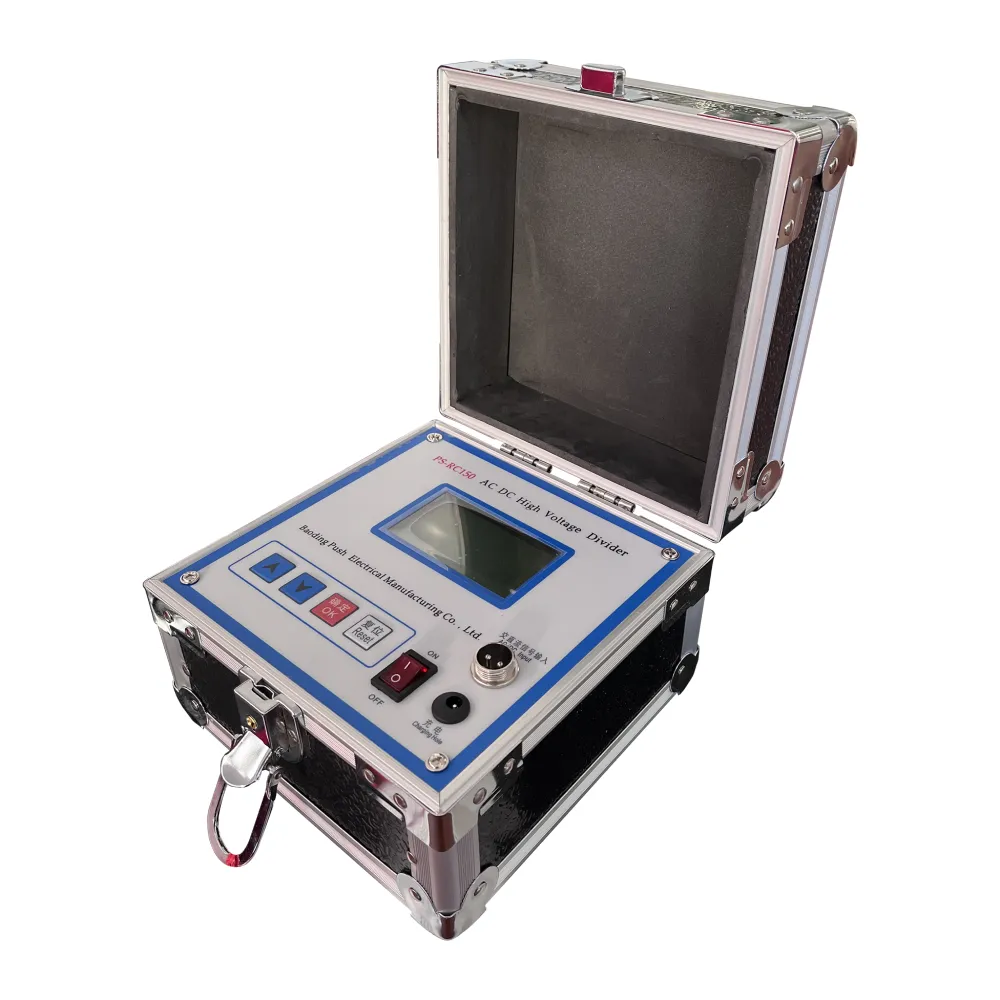

The insulation resistance test measures the resistance of the bushing insulation to ensure it is not degrading. A low insulation resistance reading can indicate moisture ingress or insulation breakdown, which compromises the bushing's effectiveness. During this test, technicians apply a DC voltage to the bushing and measure the current that flows through it, allowing for the calculation of insulation resistance. A resistance value below the manufacturer's recommended specifications may warrant further investigation or replacement.

bushing test in transformer

Power factor testing assesses the dielectric losses in the bushing insulation. A high power factor indicates that the insulation may be degrading and generating excessive heat, which can lead to further deterioration. This test involves applying an AC voltage and measuring the phase angle between the voltage and the current flow in the bushing. By comparing the power factor of the bushing to historical data, technicians can determine if maintenance or replacement is necessary.

Partial discharge testing is another crucial method used to identify insulation defects within the bushing. Partial discharges occur when electrical stress exceeds the insulation’s capability, leading to localized breakdown. This testing is important because partial discharges can precede complete insulation failure. By employing specialized sensors, technicians can detect these discharges and assess their severity, allowing them to make informed decisions regarding maintenance.

The results from these tests provide valuable insights into the condition of transformer bushings. Regular testing not only enhances operational reliability but also aids in predictive maintenance strategies, which can minimize unplanned outages and extend the life of the transformer. In many industries, including utility and manufacturing, understanding the health of transformer bushings is critical to ensuring continuous and safe operations.

In conclusion, bushing tests are a necessary part of transformer maintenance, offering essential data to predict possible failures and ensure safe operation. By employing effective testing methods, organizations can preserve their assets, optimize performance, and ultimately contribute to a more reliable electrical infrastructure. Regular testing of transformer bushings is not just a best practice; it is a proactive approach that pays dividends in reliability and safety.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024