English

English

c tan delta test on electric bushings is done using

The Importance of the C-Tan Delta Test on Electric Bushings

Electrical systems play a vital role in the smooth operation of power plants, substations, and various electrical installations. Among the critical components in these systems are electric bushings, which serve as insulators that facilitate the entrance of conductors into transformers, reactors, and other high-voltage equipment. As these components are integral to maintaining the reliability and safety of electrical systems, it is crucial to monitor their health regularly. One of the standard tests employed for assessing the condition of electric bushings is the C-Tan Delta test.

The C-Tan Delta test measures the dielectric properties of insulating materials, helping to identify weaknesses that could lead to failure. This test evaluates the insulation’s capacitance and the dissipation factor, or tan delta, which indicates the efficiency of the insulation. A higher tan delta value signifies increased losses due to heating within the insulating material, potentially leading to reduced performance and eventual breakdown.

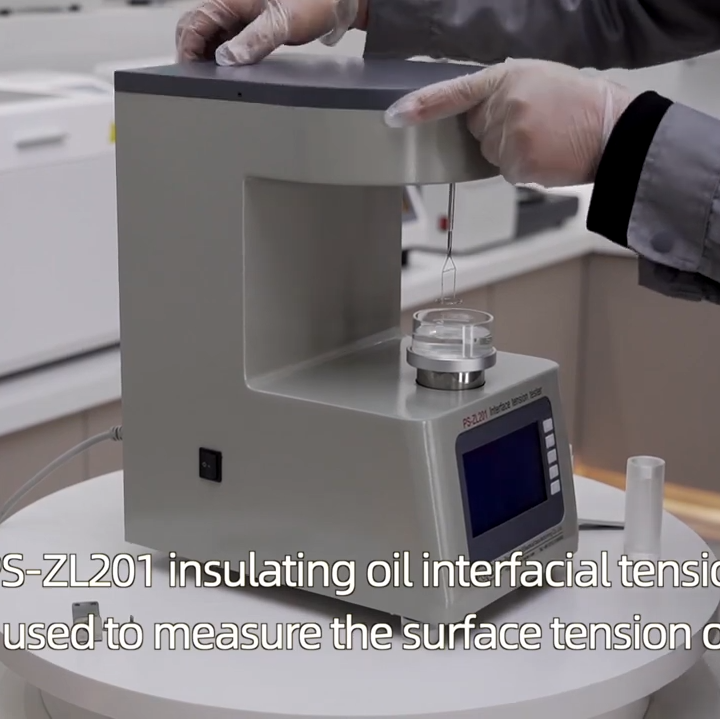

Performing a C-Tan Delta test involves applying a known AC voltage to the bushing while measuring the resulting current. The test equipment typically includes high-voltage transformers, capacitive dividers, and precise measurement tools to ensure accurately capturing the data. Technicians analyze the tan delta value and compare it against established benchmarks to determine the condition of the insulation. It is generally considered that a tan delta value below 0.5% is acceptable, while values above this threshold warrant further investigation and potential maintenance action.

c tan delta test on electric bushings is done using

The C-Tan Delta test is advantageous because it can be conducted on-line, meaning equipment can be tested without taking it offline, thereby minimizing operational disruptions. This feature is particularly beneficial for facilities that require continuous operation, such as power generation plants. Through regular C-Tan Delta testing, operators can detect subtle changes in bushing performance over time, facilitating proactive maintenance decisions rather than reactive ones.

Moreover, the data obtained from these tests can provide insights into the aging process of insulation materials. By identifying trends in the C-Tan Delta values, maintenance teams can formulate strategies for bushing replacement or refurbishment before a failure occurs. This predictive maintenance strategy ultimately enhances system reliability and reduces the risk of unexpected outages.

Additionally, the C-Tan Delta test is not limited to electric bushings; it can also be applied to transformers, cables, and various other insulating materials. As such, it serves as an essential tool in a broader condition monitoring program.

In conclusion, the C-Tan Delta test on electric bushings is a crucial diagnostic tool that aids in maintaining the integrity and performance of electrical systems. By providing critical information about insulation health, this test helps in ensuring operational reliability and safety, ultimately leading to more efficient and cost-effective maintenance strategies. Regularly conducting the C-Tan Delta test is a proactive step toward preventing equipment failure and extending the life of electrical assets.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024