English

English

Cable Insulation Testing Standards and Best Practices for Safety and Performance

Understanding Cable Insulation Test Standards

In the world of electrical engineering and telecommunications, the integrity of cable insulation is paramount. Insulation protects conductors from electrical interference and prevents short circuits, making it essential for safety and performance. To ensure that insulation materials meet regulatory and safety standards, various cable insulation test standards have been established globally. This article delves into the importance, methodologies, and common standards associated with cable insulation testing.

Importance of Cable Insulation Testing

Electrical cables are widely used in various industries, including automotive, telecommunications, and construction. The insulation surrounding these cables is crucial for several reasons

1. Safety Proper insulation prevents electrical shocks and protects users from potential hazards. 2. Performance High-quality insulation minimizes signal loss and enhances the overall efficiency of electrical systems. 3. Durability Robust insulation extends the lifespan of cables by protecting them from environmental conditions, chemicals, and physical wear.

Given these factors, it is vital to adhere to established testing standards to ensure that cables will perform safely and effectively throughout their intended lifespan.

Methodologies of Cable Insulation Testing

Cable insulation testing involves a series of standardized assessments designed to measure various properties of insulation materials. The primary methodologies include

1. Dielectric Strength Testing This test measures the maximum voltage an insulating material can withstand before failing. Conducted typically with an alternating current (AC), the insulation is subjected to increasing voltage levels until breakdown occurs. This helps evaluate the insulation's ability to prevent electrical leakage.

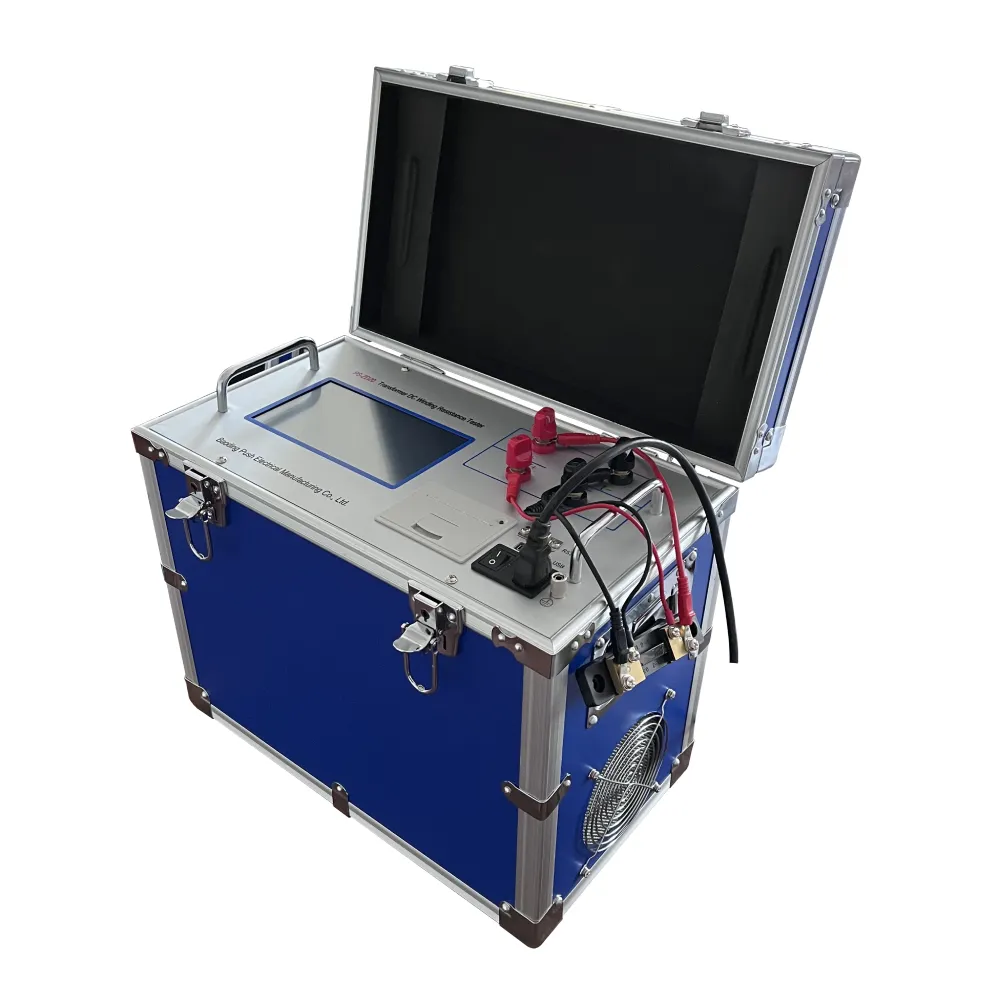

2. Resistance Testing (Megger Testing) This involves measuring the resistance of the insulation to direct current (DC). A megohmmeter is used to apply a voltage across the insulation, and resistance readings are taken. High resistance values indicate good insulation, while low values may suggest deterioration or failure.

cable insulation test standard

3. Thermal Aging Tests Insulation materials are subjected to elevated temperatures for extended periods to simulate long-term use. The impact on mechanical properties and electrical performance is then assessed to evaluate how well the insulation can withstand thermal stresses over time.

4. Water Immersion Tests This method evaluates how the insulation reacts when exposed to water. The cable insulation may absorb moisture, leading to degradation. By immersing cables in water and observing changes in resistance and dielectric strength, engineers can predict lifespan and performance in humid environments.

Common Standards for Cable Insulation Testing

Several organizations have established standards for cable insulation testing. Key standards include

1. International Electrotechnical Commission (IEC) Standards IEC 60068 covers various environmental testing methods, including insulation testing for cables and wires. This standard emphasizes the importance of testing insulation under various conditions to ensure reliability.

2. Institute of Electrical and Electronics Engineers (IEEE) Standards IEEE 383 provides guidelines for the testing of cables for nuclear power generating stations, focusing on insulation integrity during harsh conditions.

3. American Society for Testing and Materials (ASTM) ASTM D149 outlines the dielectric strength tests for electrical insulating materials, providing a framework for evaluating insulation properties.

4. National Fire Protection Association (NFPA) Standards NFPA 70E provides guidelines for safe electrical work practices, which include recommendations for testing cable insulation in industrial settings to prevent electrical hazards.

Conclusion

Cable insulation test standards are essential in ensuring the reliability, safety, and longevity of electrical cables. Through rigorous testing methodologies like dielectric strength and resistance testing, manufacturers can demonstrate that their products meet necessary safety regulations and industry standards. As technology continues to evolve, so too will the standards and methodologies surrounding cable insulation testing, ensuring that electrical systems remain safe and efficient. Continuous adherence to these standards not only supports quality assurance but also cultivates trust in the industry as a whole, paving the way for innovations that will shape the future of electrical connectivity.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024