English

English

Testing Procedures for Capacitive Voltage Transformers in Electrical Applications

Testing of Capacitive Voltage Transformers

Capacitive Voltage Transformers (CVTs) serve a pivotal role in electrical systems, primarily in high-voltage applications. By stepping down high voltage levels to manageable levels, CVTs provide operational safety and measurement accuracy for protective relays and other instrumentation. Proper testing of these transformers is essential to ensure their reliability and functionality in various operational conditions.

Understanding CVTs

CVTs operate based on the principles of capacitance and are designed to handle high voltages while providing a proportional voltage output that can be easily measured. Typical applications include monitoring voltage in power systems, protection of electrical equipment, and facilitating measurements in telemetry and control systems.

Importance of Testing

Testing CVTs is crucial for several reasons. First, it ensures the equipment operates efficiently within its specified parameters. Even slight deviations or faults can lead to failures or inaccurate measurements, which could jeopardize the overall safety and efficiency of an electrical system. Second, testing allows for the assessment of insulation integrity and capacitance values, ensuring that the transformer meets the required performance standards.

Testing Procedures

1. Insulation Resistance Testing This test evaluates the state of insulation within the CVT. A high resistance value indicates good insulation health. Technicians typically use a megohmmeter to apply a high voltage to the insulation and measure the resistance.

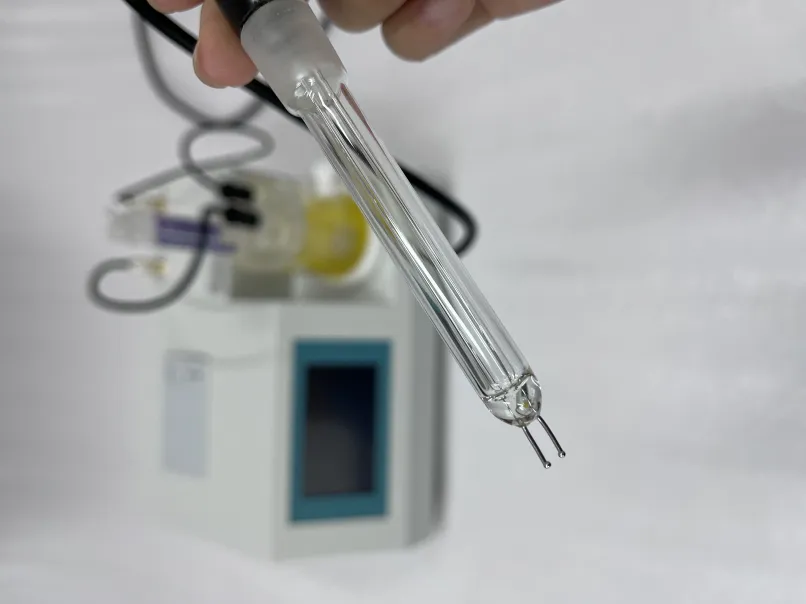

capacitive voltage transformer testing

2. Power Factor Testing This test helps to determine the dielectric losses in the insulation system. By applying an AC voltage at the rated frequency, the power factor can be computed, providing insights into the insulation quality.

3. Capacitance Measurement Accurately measuring the capacitance is vital as it directly influences the performance of the CVT. Capacitance test equipment is used, and the values are compared to manufacturer specifications.

4. Ratio Testing Ratio tests verify that the output voltage of the CVT corresponds correctly to the high-voltage input. This involves applying a known high voltage and measuring the resultant low voltage output, ensuring that it aligns with the expected transformation ratio.

5. Frequency Response Testing This procedure examines the frequency characteristics of the CVT, looking for non-linearities or other issues that could affect performance in varying operational conditions.

6. Dynamic Testing This involves observing the CVT’s response under varying conditions of load and voltage transients, helping to simulate real-world operational environments.

Conclusion

The testing of Capacitive Voltage Transformers is a fundamental aspect of maintaining the integrity and reliability of electrical power systems. Through a systematic approach to testing—including insulation resistance, power factor, capacitance, ratio, frequency response, and dynamic tests—engineers can better ensure that CVTs are functioning as intended. The results of these tests not only help in identifying potential issues before they lead to equipment failures but also play a critical role in ensuring compliance with regulatory standards and guidelines. As electrical grids evolve and new technologies emerge, ongoing testing and evaluation of CVTs will remain a cornerstone of effective power system management.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024