English

English

Checking Transformer Parameters Using a Multimeter for Accurate Measurements

Checking Transformers with a Multimeter A Comprehensive Guide

Transformers are crucial components in electrical systems, playing a significant role in voltage conversion and energy distribution. Whether in power generation, transmission, or electrical devices, ensuring that transformers function properly is vital for system reliability and efficiency. One effective way to check the functionality of a transformer is by using a multimeter. This article will explore the steps and techniques for checking transformers with a multimeter, ensuring you can identify issues early and maintain the integrity of your electrical systems.

Understanding Transformers and Their Importance

A transformer is an electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. They are primarily used to increase (step-up) or decrease (step-down) voltage levels. Regular maintenance and testing of transformers are essential to prevent failures, outages, and potential hazards. By using a multimeter, technicians can perform various checks to assess a transformer's health efficiently.

Tools of the Trade The Multimeter

A multimeter is a versatile instrument that can measure voltage (both AC and DC), current, and resistance. For transformer testing, the essential functions are AC voltage measurement, resistance testing, and continuity checks. A digital multimeter (DMM) is recommended for its accuracy and ease of use.

Steps to Check a Transformer with a Multimeter

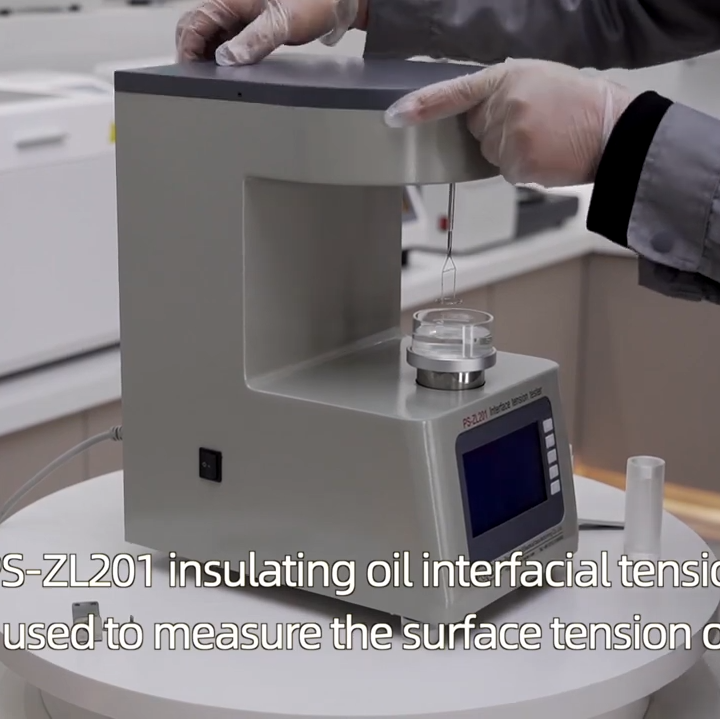

1. Safety First Before you start any testing, ensure that the power supply to the transformer is disconnected. Safety gear such as gloves and goggles should be worn to protect against electrical hazards.

transformer checking with multimeter

2. Visual Inspection Conduct a visual inspection of the transformer for any signs of physical damage, such as oil leaks, burnt components, or corrosion. Document any visible issues, as they may indicate deeper problems.

3. Check Primary and Secondary Voltage - Reconnect Power Once you’ve conducted your visual inspection, carefully reconnect the power supply to the transformer. - Set the Multimeter Set the multimeter to measure AC voltage. - Measure Input Voltage Attach the multimeter leads to the primary side terminals of the transformer and note the AC voltage reading. This should align with the expected voltage rating of the transformer. - Measure Output Voltage Next, measure the voltage at the secondary side terminals. Again, compare this reading to the expected output voltage.

4. Testing Resistance - Disconnect the power supply and isolate the transformer from the circuit. - Set the multimeter to the resistance (ohms) setting. - Measure the resistance across the primary and secondary terminals. The readings should be within the manufacturer’s specified range. A significantly high or low resistance may indicate a fault in the winding.

5. Continuity Testing - Perform a continuity test by checking between the windings and the ground. Connect one lead of the multimeter to one winding terminal and the other lead to the transformer's core. There should be no continuity (infinite resistance) between the winding and the core. Any continuity indicates insulation failure.

6. Interpret the Results After all measurements, compare your results with the manufacturer’s specifications. Any discrepancies might require further investigation or professional assistance.

Conclusion

Regular checks using a multimeter can prevent transformer failures and ensure the reliability of electrical systems. By following these steps, you can efficiently assess the condition of a transformer and determine if any maintenance or repairs are needed. Always prioritize safety and consult a professional for extensive repairs or if you are uncertain about any readings. Through diligent testing and maintenance, you can extend the lifespan of transformers and ensure safe, efficient operation in your electrical systems.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024