English

English

Transformers Commissioning Process and Best Practices for Efficient Operation

Commissioning of Transformers Ensuring Reliable Electrical Infrastructure

The commissioning of transformers is a critical process in the establishment of reliable electrical infrastructure. Transformers play an essential role in power distribution systems, stepping down high voltages from transmission lines to usable levels for residential, commercial, and industrial applications. To ensure that these devices operate efficiently and safely throughout their operational lifecycle, a detailed commissioning process is necessary.

Understanding the Importance of Commissioning

Commissioning involves a systematic process of verifying and validating that the transformer installation meets the design specifications and operational requirements. This process is crucial for identifying potential issues before the transformer is put into service. A thorough commissioning process helps to avoid costly downtimes, ensures compliance with safety regulations, and enhances the overall lifespan of the transformer.

Steps Involved in Transformer Commissioning

The commissioning process of a transformer typically consists of several key steps

1. Pre-Commissioning Inspection Before installation, transformers must undergo a detailed inspection. This includes checking the physical condition of the transformer, verifying that all components are intact, and ensuring that the equipment has been manufactured according to the specified standards. Any discrepancies found during this phase may require corrective actions before further testing.

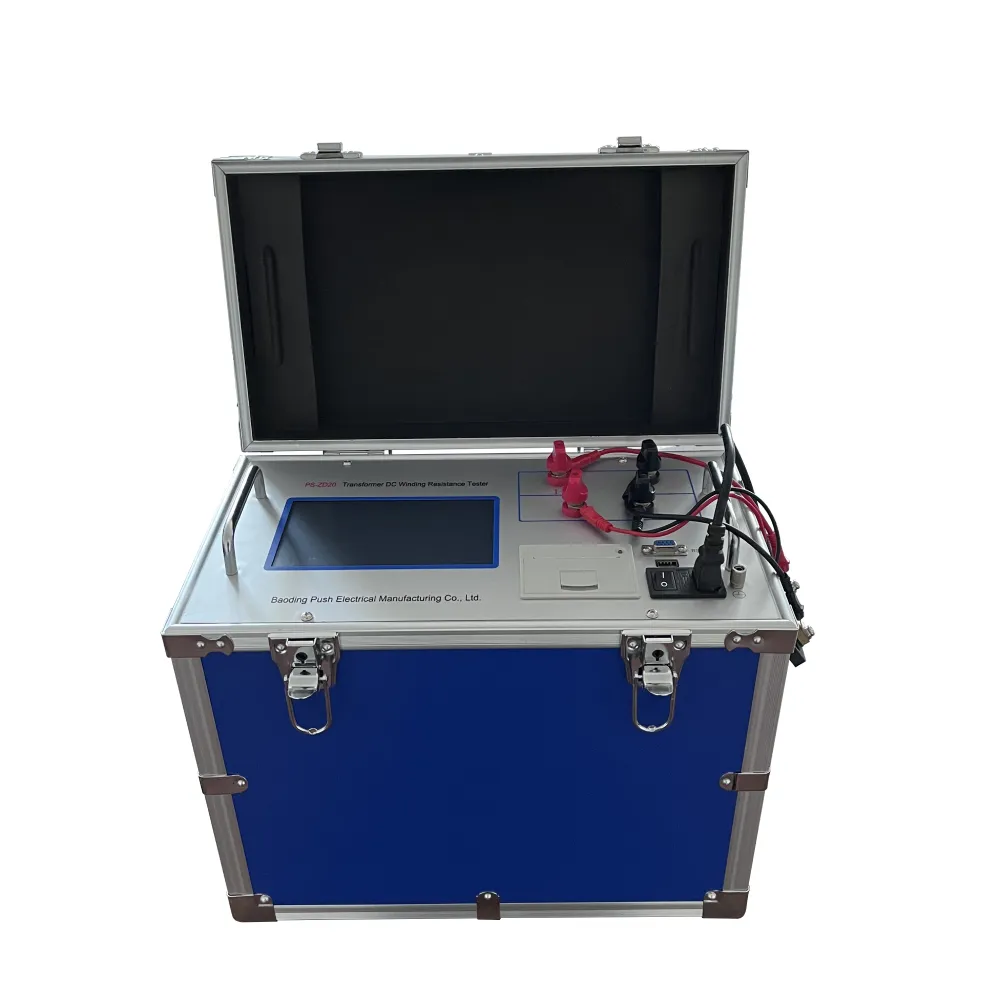

2. Electrical Testing Once the transformer is installed, a series of electrical tests are conducted to assess its performance. These include insulation resistance tests, power factor testing, and winding resistance measurements. Insulation resistance tests help confirm that the insulation system is free from flaws, while winding resistance measurements ensure that the windings are correctly connected.

commissioning of transformer

3. Functional Testing After the electrical tests, functional tests are performed to verify the transformer’s operational capabilities under normal conditions. This includes monitoring voltage and current levels during load conditions to ensure that the transformer can effectively handle the expected operational loads.

4. Protection System Testing The protection systems associated with transformers, such as relays and circuit breakers, are fundamental for operational safety. Testing these systems during commissioning is essential to ensure that they will respond properly to overloads or faults, preventing potential damage and ensuring the safety of the overall system.

5. Thermal Imaging and Vibration Analysis Advanced diagnostic tools like thermal imaging cameras and vibration analysis equipment can provide real-time data about the operating conditions of a transformer. These tools help identify hotspots, mechanical imbalances, or other early signs of failure that may not be detectable through traditional inspection methods.

6. Documentation and Reporting Throughout the commissioning process, it is important to document all findings, test results, and corrective actions taken. This documentation serves as a record of the transformer’s commissioning process and can be invaluable for future reference, maintenance planning, and troubleshooting.

Conclusion The Path to Reliability

The commissioning of transformers is a vital process that lays the groundwork for safe and efficient electrical operation. By adhering to a comprehensive commissioning protocol, utilities and engineers can ensure that transformers operate reliably, minimizing risks and ensuring long-term performance. As global demand for electricity continues to rise, investing in proper commissioning practices not only enhances system reliability but also contributes to the overall resilience of the power grid.

In summary, thorough commissioning ensures that every transformer operates within its specified parameters, ultimately leading to a more robust and dependable electrical infrastructure. As technology evolves, the commissioning process also adapts, incorporating innovative testing methods and tools to meet the ever-changing demands of the electrical industry. Through careful attention to commissioning, organizations can protect their assets, improve service delivery, and contribute to a more sustainable energy future.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024