English

English

Testing for Electrical Continuity and Insulation Effectiveness in Electrical Systems

Continuity and Insulation Testing Ensuring Electrical Safety and Performance

In the realm of electrical maintenance and safety, continuity and insulation tests play a critical role in verifying the reliability and integrity of electrical systems. These tests are essential for ensuring that electrical installations operate safely, efficiently, and without risk of leakage or failure.

What is Continuity Testing?

Continuity testing is a method used to assess whether an electrical circuit is complete and free of breaks. This test is crucial for ensuring that current can flow uninterrupted through the circuit. During continuity testing, a low-voltage signal is sent through the circuit, and the results are evaluated. If the circuit is continuous, the tester will indicate a low resistance reading. On the other hand, a high resistance or open circuit reading indicates a break, which could lead to failures or hazards if not addressed.

Continuity tests are commonly performed on wiring systems, electrical panels, and connections

. By identifying issues early, continuity testing helps prevent potential electrical failures that could lead to equipment damage, increased operational costs, or even hazardous situations like electrical fires.What is Insulation Testing?

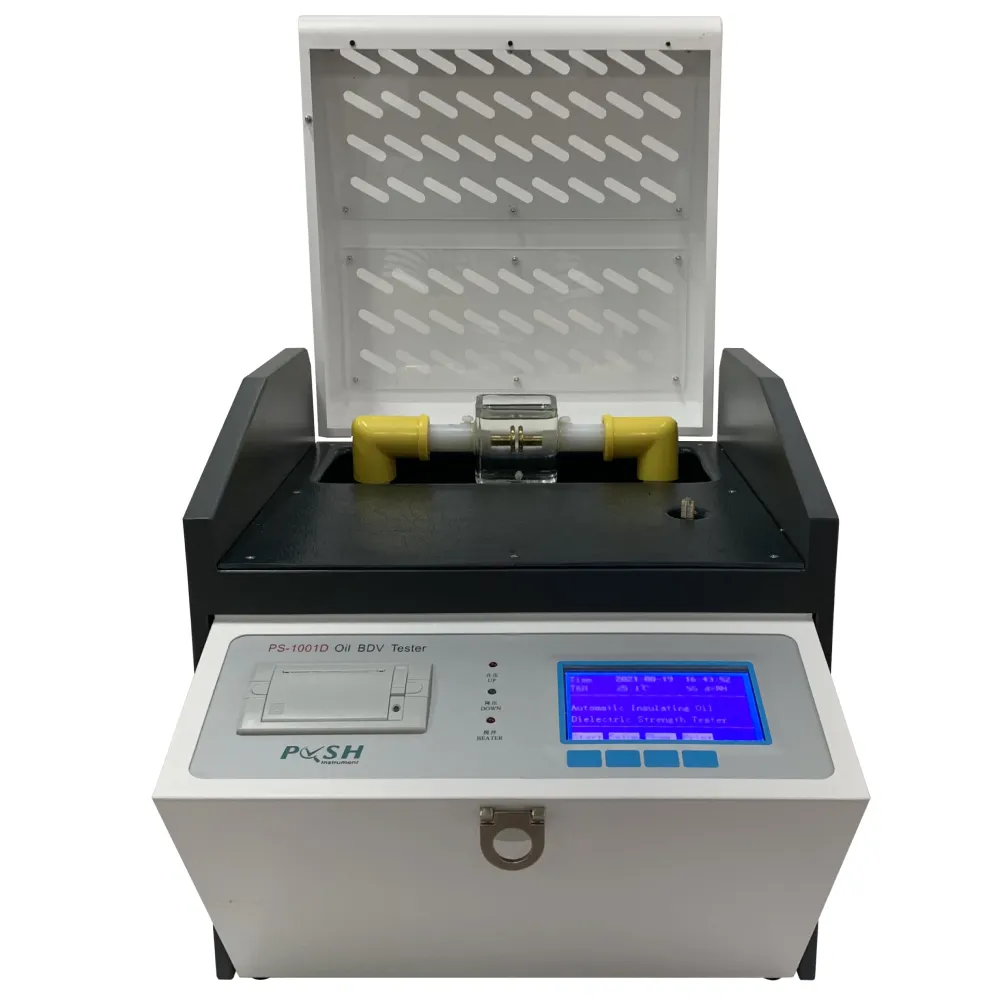

continuity and insulation test

Insulation testing, often referred to as insulation resistance testing, is another critical process designed to evaluate the effectiveness of insulation in electrical conductors. Proper insulation is necessary to prevent electrical leakage, which can lead to severe safety hazards. During an insulation test, a high-voltage signal is applied to measure the resistance of the insulation material. The results are expressed in megaohms (MΩ); a higher resistance indicates better insulation.

Insulation testing is particularly important in environments where moisture, chemicals, or extreme temperatures may compromise insulation materials. Regular insulation tests can identify degradation or damage that could lead to unexpected failures. By ensuring that insulation resistance remains above a certain threshold, operators can enhance safety and extend the lifespan of electrical equipment.

The Importance of Regular Testing

Conducting regular continuity and insulation tests is not just a best practice; it is a necessity in many industrial and commercial settings. These tests help in adhering to safety regulations and standards such as those set by the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA).

In conclusion, continuity and insulation testing are essential tools in maintaining electrical system safety and efficiency. By identifying issues early, these tests not only ensure compliance with safety standards but also help in preventing costly downtime and improving the longevity of electrical equipment. Regular testing should be integrated into routine maintenance schedules to promote safety and reliability in electrical operations.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024