English

English

crude oil distillation column

Understanding Crude Oil Distillation Columns An Essential Process in Oil Refining

Crude oil distillation is one of the fundamental processes in the petroleum refining industry. This separation technique is crucial for converting crude oil into usable products, such as gasoline, diesel, kerosene, and other petrochemicals. At the heart of this process lies the crude oil distillation column, an intricate piece of equipment that facilitates the separation of different hydrocarbon components based on their boiling points.

The Basics of Crude Oil Distillation

Crude oil is a complex mixture of hydrocarbons and various organic compounds. The initial step in refining involves heating the crude oil to temperatures ranging from 350 to 400 degrees Celsius. This heating converts the liquid into vapor, which then enters the distillation column. The column is typically tall and cylindrical, allowing for a high degree of fractionation — the separation of mixtures into individual components.

As the vapor ascends the distillation column, it encounters a series of trays or packing material. These structures facilitate the contact between rising vapor and descending liquid, promoting mass transfer and heat exchange. As the vapor rises through the column, it cools and condenses at various heights, depending on the boiling points of the hydrocarbons.

Principles of Separation in Distillation Columns

The separation in the distillation column is based on the concept of relative volatility, which is the tendency of a substance to vaporize compared to another. Each hydrocarbon component has its own specific boiling point, and as the temperature decreases at higher points in the column, heavier components condense back into liquid form, while lighter fractions continue to rise.

This staged process is often described using the theory of equilibrium stages. Each tray in the column acts as a stage where vapor and liquid contact occurs until equilibrium is reached. The lighter fractions, such as propane and butane, exit the top of the column and are collected as overhead products, while heavier fractions like diesel and residual oils are withdrawn from the bottom.

crude oil distillation column

Design and Operation of Distillation Columns

The design of a crude oil distillation column takes into account various factors, including column diameter, height, tray or packing type, and operational conditions such as temperature and pressure. These parameters significantly impact the column's efficiency and the purity of the separated components.

To optimize performance, refiners often monitor and adjust the operational parameters in real-time. Advanced control systems help manage the heat input, reflux ratio, and the flow rates of feeds and products. Efficient operation is crucial, as it not only maximizes yields but also minimizes energy consumption, which is a significant cost driver in refining processes.

Environmental Considerations and Innovations

In recent years, the petroleum refining industry has faced increased pressure to reduce environmental impacts associated with crude oil distillation. Innovations in column design and operation focus on improving energy efficiency and reducing emissions. Techniques such as the integration of heat exchange systems and the use of advanced materials for construction are being employed to enhance sustainability.

Moreover, the rising trend towards biofuels and alternative energy sources has prompted research into modifying existing distillation techniques to accommodate these new fuels. The flexibility and efficiency of crude oil distillation columns make them adaptable to these changes, showcasing their vital role in the transition towards a more sustainable energy landscape.

Conclusion

The crude oil distillation column is a cornerstone of the petroleum refining process, enabling the efficient separation of valuable hydrocarbon products from crude oil. Its design, operation, and the underlying principles of separation are critical for maximizing yield and minimizing environmental impact. As the industry continues to evolve in the face of environmental challenges, advancements in distillation technology will play an essential role in shaping the future of oil refining, balancing economic viability with sustainability goals.

-

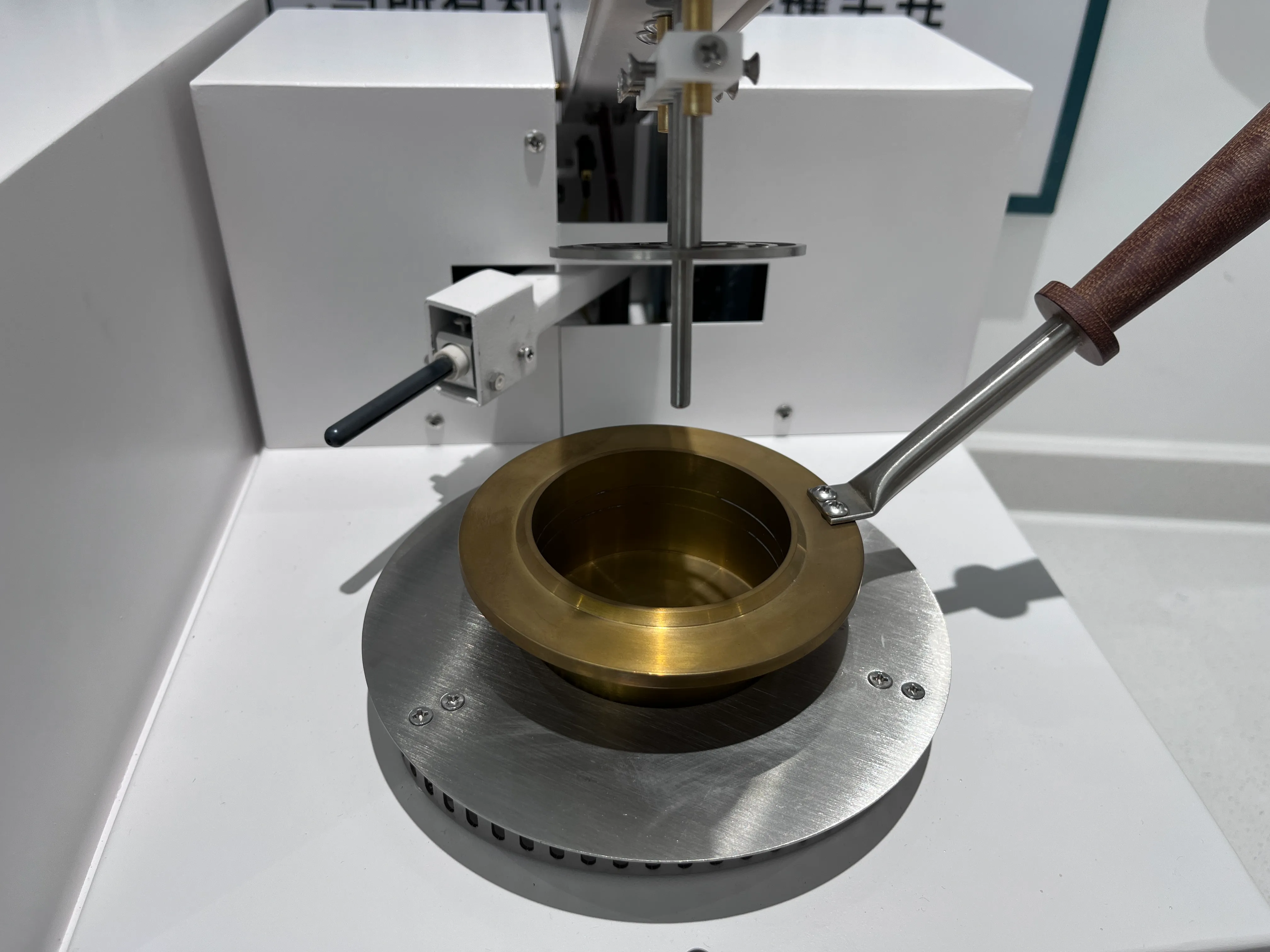

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024