English

English

ct tan delta test

Understanding the CT Tan Delta Test A Crucial Tool for Electrical Equipment Maintenance

The constantly evolving field of electrical engineering calls for effective and efficient methods to ensure the reliability and safety of electrical equipment. One of the most critical tests utilized in this context is the CT Tan Delta test, also known as the insulation power factor test. This diagnostic technique primarily focuses on assessing the insulation properties of electrical apparatus, particularly in transformers and other high-voltage equipment.

What is the CT Tan Delta Test?

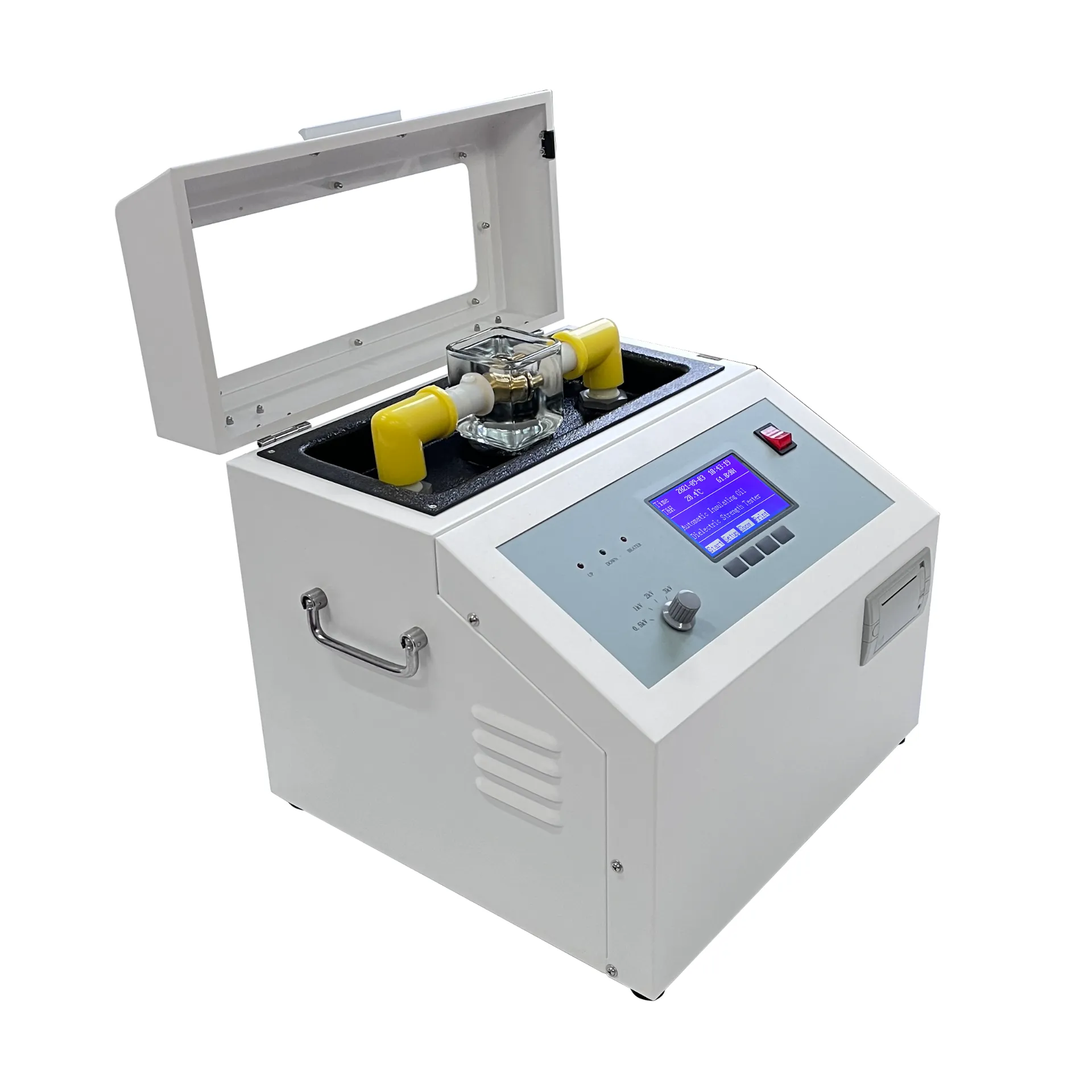

The CT Tan Delta test measures the insulation's dielectric response under applied voltage conditions. The term tan delta refers to the tangent of the loss angle, which essentially describes how much energy is lost in the dielectric material when subjected to an alternating electric field. In this context, the test evaluates both the resistive (real) and reactive (imaginary) components of the insulation system.

During a CT Tan Delta test, an alternating current is introduced, and the resulting phase difference between the voltage across the insulation and the current flowing through it is measured. This phase difference indicates how much energy is dissipated as heat, thereby directly correlating to the quality of the insulation. A lower tan delta value indicates a healthier insulation system, while a higher value suggests deterioration or potential failure.

Why is the CT Tan Delta Test Important?

Electrical insulation is crucial for the safe operation of equipment, preventing short circuits, electrical fires, and other hazards. Regular testing of insulation using the CT Tan Delta method provides several key advantages

ct tan delta test

1. Predictive Maintenance The test serves as a proactive measure, allowing maintenance teams to detect insulation degradation before catastrophic failures occur. This predictive capability is fundamental to extending the life of electrical equipment.

2. Safety Assurance High-voltage equipment operates under extreme conditions, making insulation failure potentially disastrous. The CT Tan Delta test enhances safety protocols by identifying vulnerable areas in a system, ultimately safeguarding personnel and assets.

3. Cost-Effectiveness By identifying insulation issues early, organizations can avoid costly downtime and emergency repairs. Scheduled inspections can lead to better budget management and resource allocation.

4. Regulatory Compliance Many industries are required to adhere to specific safety and quality standards. The CT Tan Delta test can help organizations demonstrate compliance with these regulations, ensuring that their equipment meets required safety standards.

How Often Should the Test Be Conducted?

The frequency of the CT Tan Delta test varies based on factors such as equipment age, usage intensity, and operational environment. Generally, it is recommended that the test be carried out at regular intervals—typically every three to five years—for newer equipment, while older or critical systems may warrant annual testing.

In conclusion, the CT Tan Delta test is an invaluable tool for assessing the health of electrical insulation systems. With its predictive capabilities, it plays a vital role in maintaining safety, optimizing costs, and ensuring compliance with regulatory standards. As the demand for reliable electrical systems continues to grow, the importance of such diagnostic tests cannot be overstated. Organizations are increasingly recognizing the necessity of implementing comprehensive testing programs that include the CT Tan Delta test as part of their overall maintenance strategies.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024