English

English

dc winding resistance

Understanding DC Winding Resistance Importance and Implications

DC winding resistance is a critical parameter in the performance and efficiency of electrical machines, especially in DC motors and transformers. It refers to the resistance offered by the windings of a device when a direct current flows through them. Understanding this concept is essential for engineers and technicians involved in the design, operation, and maintenance of electrical systems.

The Significance of Winding Resistance

Winding resistance plays a substantial role in determining the efficiency of electrical machines. High resistance in the windings leads to greater energy losses in the form of heat, which reduces the overall performance of the machine. This can result in overheating, reduced lifespan of the equipment, and potential failure. Conversely, lower resistance in windings results in better efficiency and heat management, facilitating optimal performance.

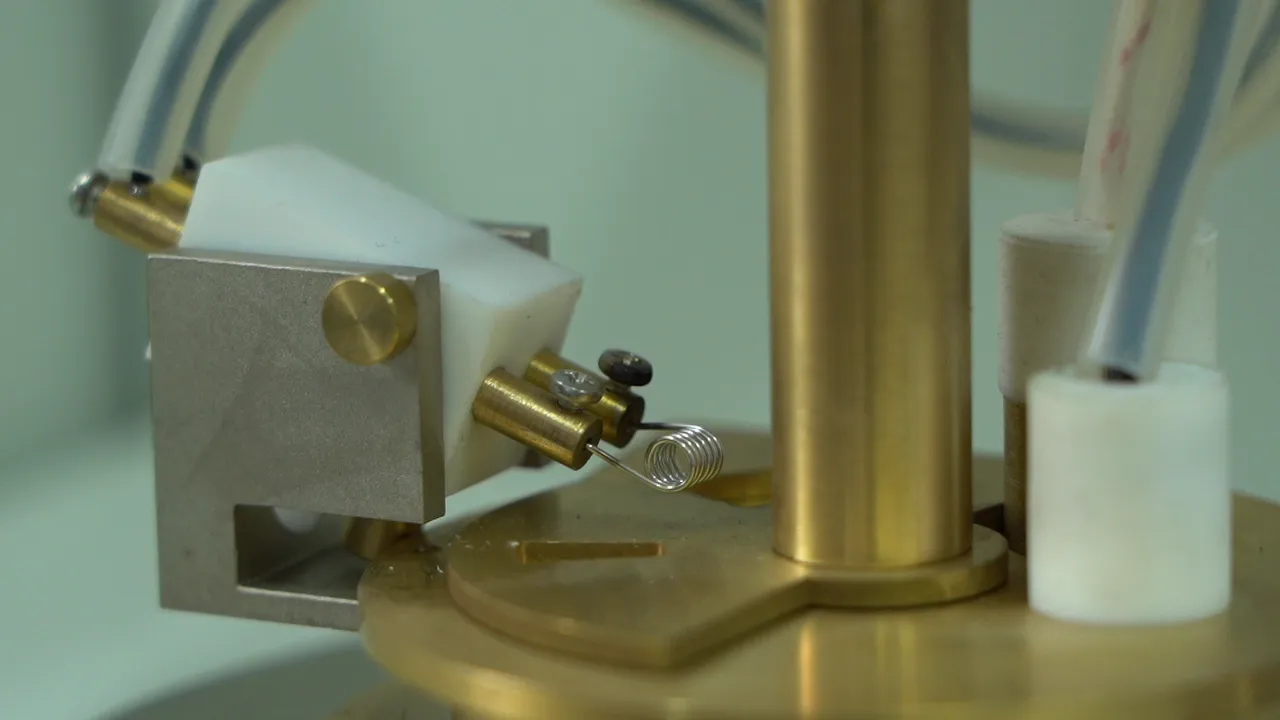

In practical applications, the winding resistance can be measured using a micro-ohmmeter, a device capable of measuring low resistances accurately. By measuring the resistance at different temperatures, engineers can calculate the temperature coefficient of resistance, which helps predict the behavior of windings under operational conditions.

Factors Affecting DC Winding Resistance

Several factors can influence the winding resistance of a machine. Firstly, temperature plays a critical role; as the temperature increases, the resistance of the winding typically increases. This phenomenon is characterized by the temperature coefficient of resistance, which varies between materials.

Secondly, the material used for the winding has a significant impact. Copper and aluminum are the most commonly used materials for windings due to their good conductivity. However, the choice of material also depends on other factors such as cost and weight. Copper, while more expensive, offers lower resistivity than aluminum, making it a more efficient choice for high-performance applications.

Additionally, the physical dimensions and the number of turns in a winding influence its resistance. Longer and thinner wire will generally have a higher resistance compared to shorter, thicker wire. The design of the winding, including the type of insulation and the way the coils are arranged, also plays a role in determining overall resistance.

dc winding resistance

Measuring DC Winding Resistance

Measuring DC winding resistance is essential for diagnosing the health of electrical machines. Regular testing helps identify issues such as short circuits, open circuits, or deterioration of the winding material. A common method involves using a direct current source to pass a known current through the winding and measuring the voltage drop across it. Ohm’s law (R = V/I) can then be applied to calculate the resistance.

It's crucial to perform these measurements at the same temperature, ideally at room temperature, to ensure consistency. If testing must occur at higher temperatures, corrections should be made to account for the change in resistance due to temperature variations.

Implications of High Winding Resistance

High winding resistance can lead to several adverse effects in electrical machines. One immediate consequence is power loss, which manifests as heat. This can affect the machine's efficiency and operational stability. Prolonged exposure to high temperatures can result in insulation breakdown, leading to short circuits or even catastrophic failures.

Moreover, increased winding resistance can affect the ground fault protection systems' functionality, potentially leading to safety issues. Hence, monitoring the winding resistance is essential for maintaining operational safety and reliability in industrial applications.

Conclusion

In conclusion, DC winding resistance is a fundamental aspect that must be considered for the effective operation of electrical machines. Understanding the factors affecting resistance, the methods of measurement, and the implications of high resistance can help engineers and technicians maintain system efficiency and reliability. Regular monitoring and testing will ensure that electrical machines operate optimally, reducing the risk of failures and promoting longevity in industrial applications. Ultimately, awareness and proactive maintenance of winding resistance can lead to significant benefits in terms of performance, safety, and cost savings.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024