TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

7 月 . 07, 2024 04:50

Back to list

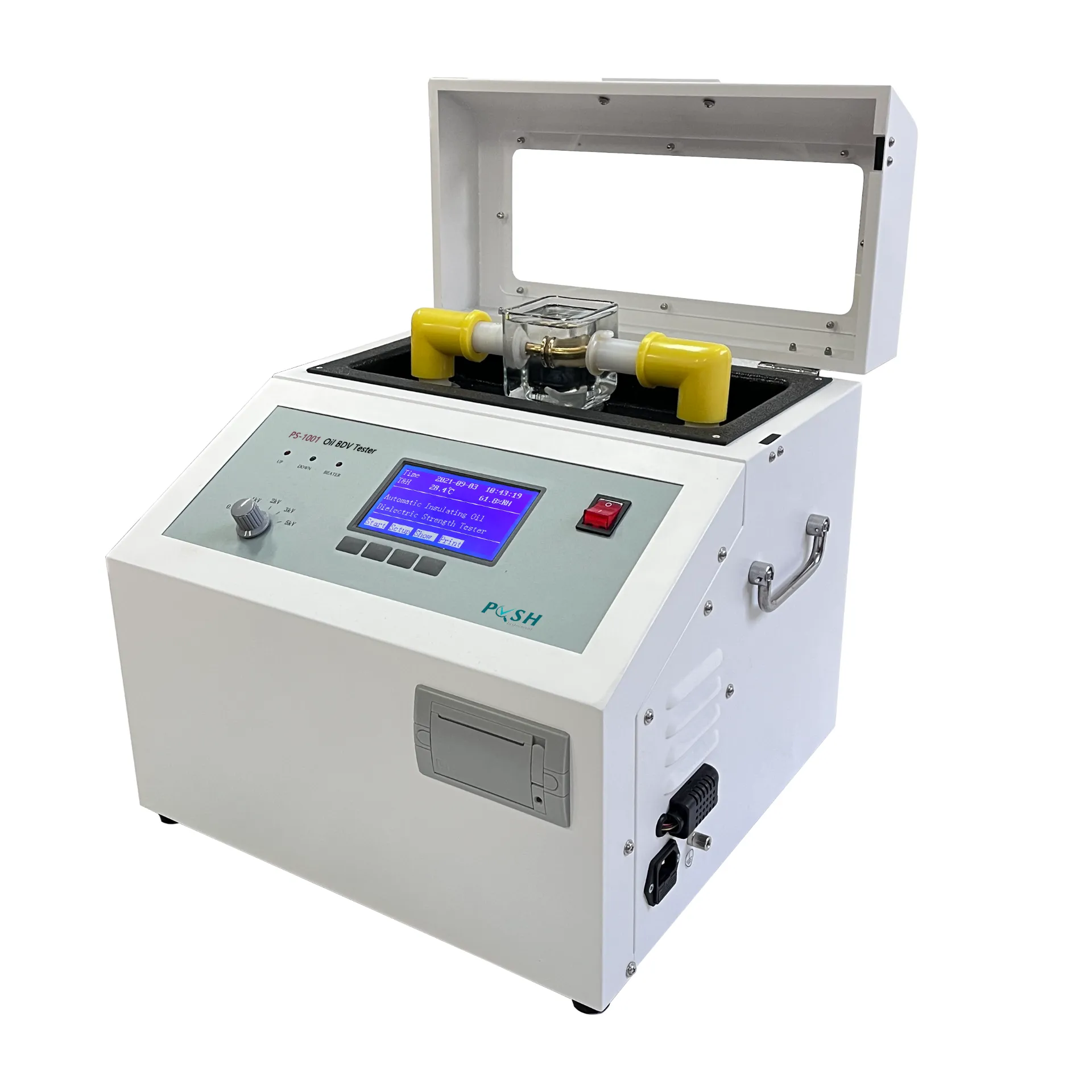

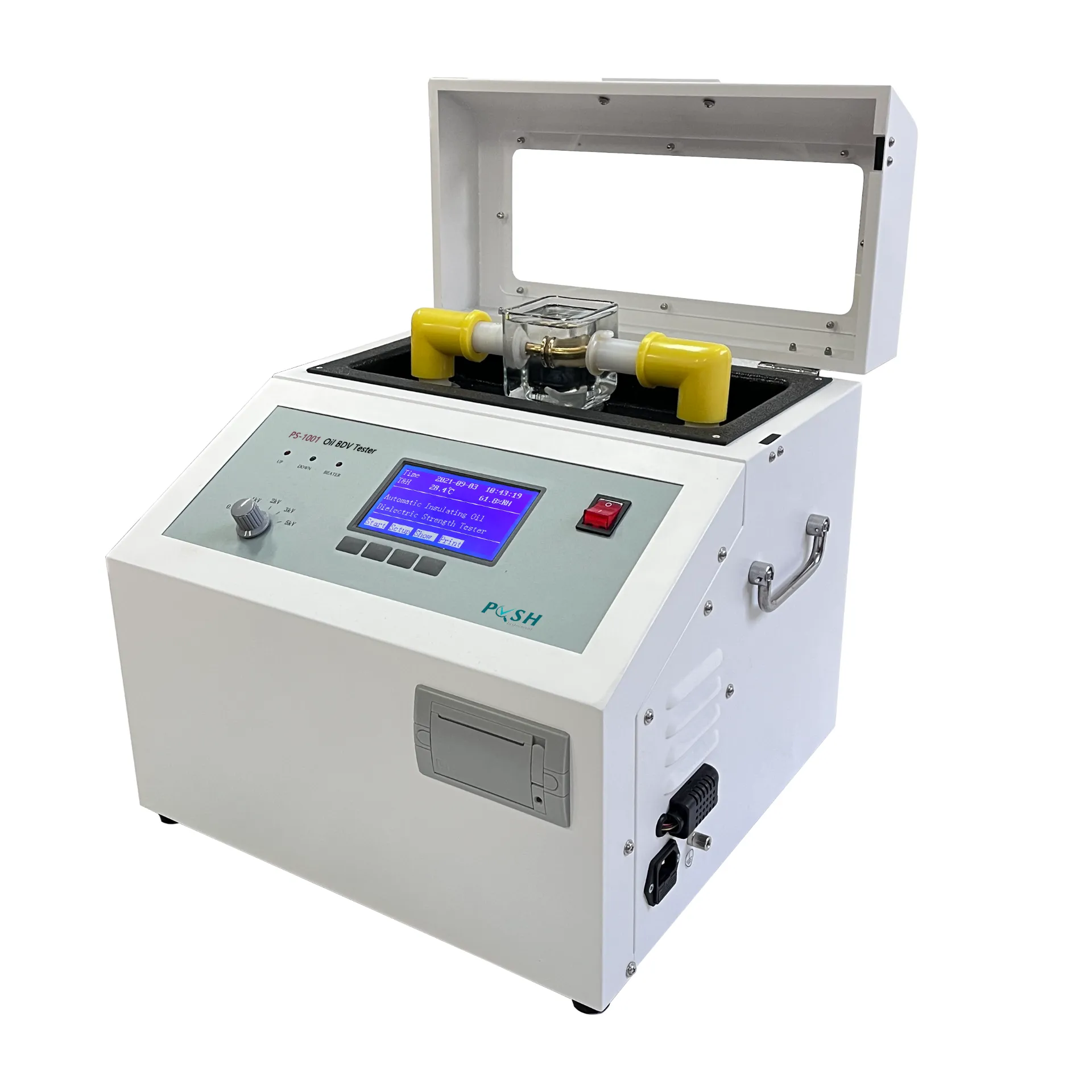

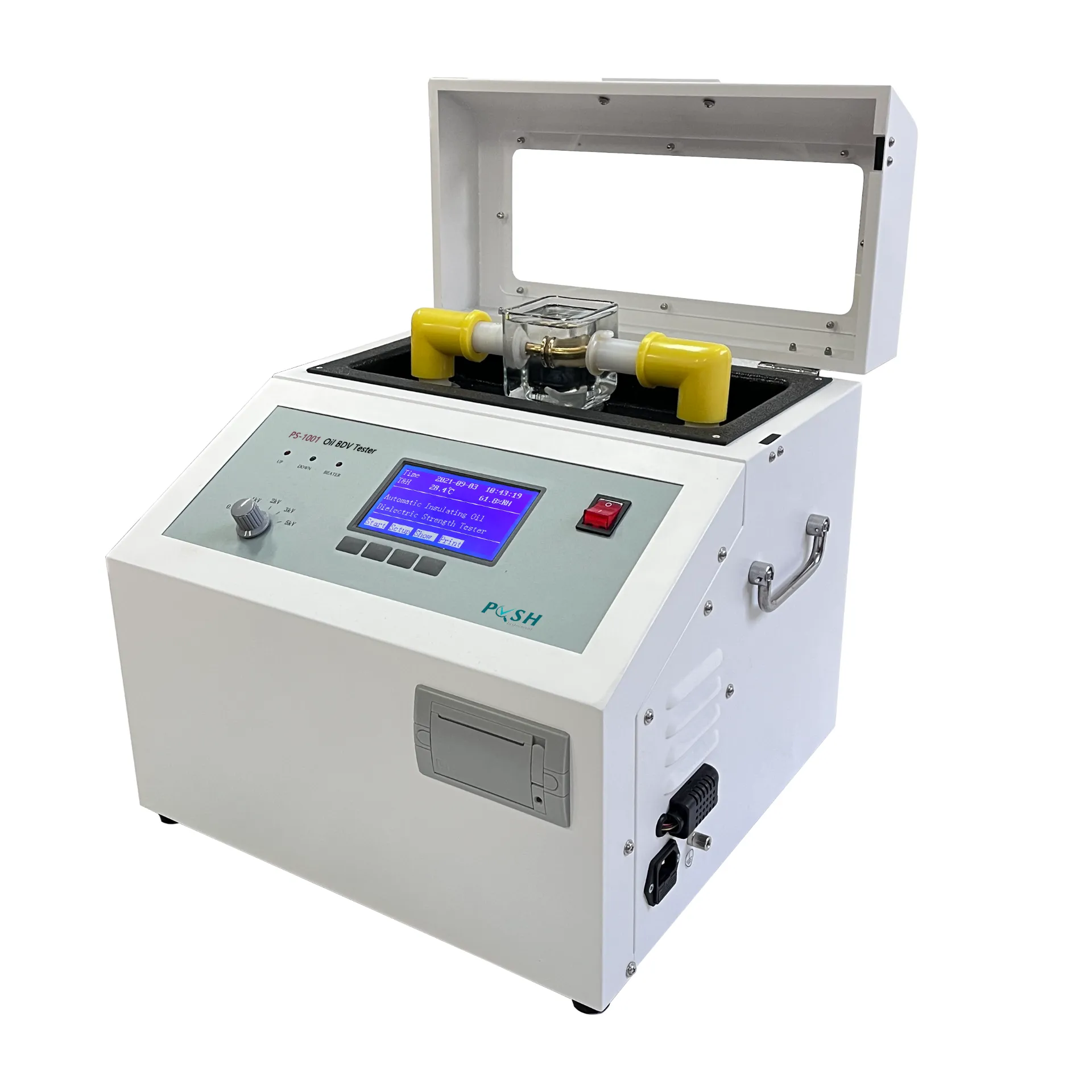

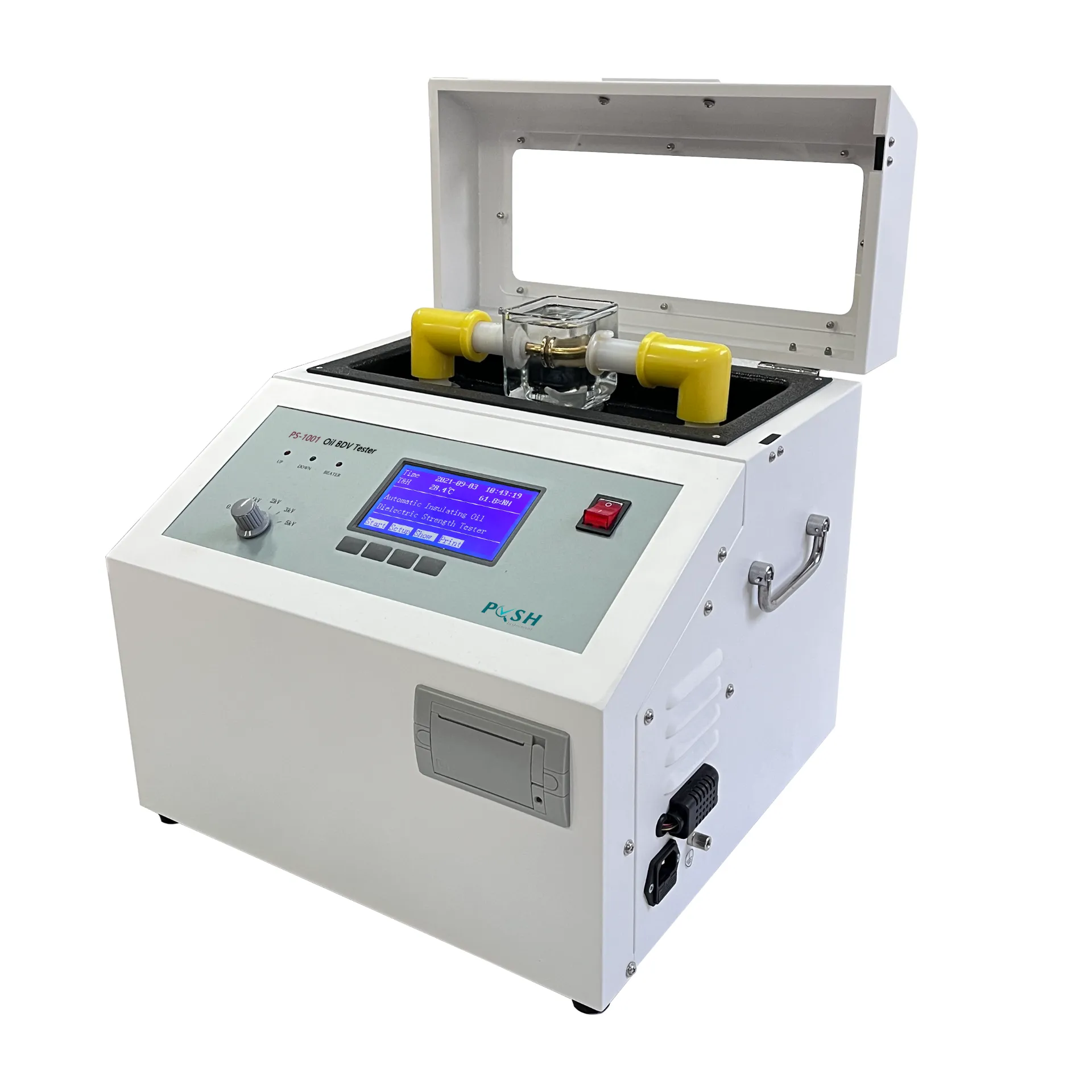

dielectric strength tester for insulating materials and electrical equipment testing applications

Dielectric withstand testers are essential tools used in the electrical industry to test the quality and safety of electrical insulation in various equipment and devices. These testers are specifically designed to measure the ability of an insulating material to withstand the application of a high voltage without breaking down. This is crucial in ensuring the reliability and longevity of electrical equipment, as breakdown of insulation can result in short circuits, equipment failure, or even electrical fires.

The dielectric withstand tester works by applying a high voltage to the insulation material and measuring the amount of current that flows through it. This test helps determine if the insulation is able to withstand the voltage without leaking current and breaking down. Dielectric withstand testers are commonly used in the production and testing of electrical cables, transformers, motors, and other equipment where insulation integrity is critical.

One of the key features of a dielectric withstand tester is its ability to test insulation at much higher voltages than the equipment will actually operate at. This is necessary to ensure that the insulation has a safety margin to prevent breakdown under normal operating conditions. The tester can accurately measure insulation resistance, leakage current, and breakdown voltage, providing valuable information about the quality of the insulation material.

In addition to testing electrical equipment during production, dielectric withstand testers are also used for routine maintenance and quality control checks. Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage

Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage dielectric withstand tester. It is recommended to perform dielectric tests periodically, especially in critical or high-voltage applications.

Dielectric withstand testers come in various configurations and designs to suit different testing requirements. Some testers are portable and handheld, suitable for field testing or on-site inspections. Others are bench-top models with more advanced features for laboratory testing and quality assurance purposes. Modern dielectric testers may also include computer interfaces for data logging and analysis, making it easier to track test results and trends over time.

In conclusion, dielectric withstand testers play a crucial role in ensuring the safety and reliability of electrical equipment by testing the integrity of insulation materials. Regular testing with a dielectric withstand tester can help prevent electrical failures, malfunctions, and accidents, ultimately saving time and money for businesses and consumers. Investing in a high-quality dielectric tester is a wise decision for any organization that relies on electrical equipment to operate efficiently and safely.

dielectric withstand tester. It is recommended to perform dielectric tests periodically, especially in critical or high-voltage applications.

Dielectric withstand testers come in various configurations and designs to suit different testing requirements. Some testers are portable and handheld, suitable for field testing or on-site inspections. Others are bench-top models with more advanced features for laboratory testing and quality assurance purposes. Modern dielectric testers may also include computer interfaces for data logging and analysis, making it easier to track test results and trends over time.

In conclusion, dielectric withstand testers play a crucial role in ensuring the safety and reliability of electrical equipment by testing the integrity of insulation materials. Regular testing with a dielectric withstand tester can help prevent electrical failures, malfunctions, and accidents, ultimately saving time and money for businesses and consumers. Investing in a high-quality dielectric tester is a wise decision for any organization that relies on electrical equipment to operate efficiently and safely.

Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage

Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage Regular testing with a dielectric withstand tester can help detect insulation degradation early on, allowing for timely repairs or replacements to prevent costly downtime and equipment damage dielectric withstand tester. It is recommended to perform dielectric tests periodically, especially in critical or high-voltage applications.

Dielectric withstand testers come in various configurations and designs to suit different testing requirements. Some testers are portable and handheld, suitable for field testing or on-site inspections. Others are bench-top models with more advanced features for laboratory testing and quality assurance purposes. Modern dielectric testers may also include computer interfaces for data logging and analysis, making it easier to track test results and trends over time.

In conclusion, dielectric withstand testers play a crucial role in ensuring the safety and reliability of electrical equipment by testing the integrity of insulation materials. Regular testing with a dielectric withstand tester can help prevent electrical failures, malfunctions, and accidents, ultimately saving time and money for businesses and consumers. Investing in a high-quality dielectric tester is a wise decision for any organization that relies on electrical equipment to operate efficiently and safely.

dielectric withstand tester. It is recommended to perform dielectric tests periodically, especially in critical or high-voltage applications.

Dielectric withstand testers come in various configurations and designs to suit different testing requirements. Some testers are portable and handheld, suitable for field testing or on-site inspections. Others are bench-top models with more advanced features for laboratory testing and quality assurance purposes. Modern dielectric testers may also include computer interfaces for data logging and analysis, making it easier to track test results and trends over time.

In conclusion, dielectric withstand testers play a crucial role in ensuring the safety and reliability of electrical equipment by testing the integrity of insulation materials. Regular testing with a dielectric withstand tester can help prevent electrical failures, malfunctions, and accidents, ultimately saving time and money for businesses and consumers. Investing in a high-quality dielectric tester is a wise decision for any organization that relies on electrical equipment to operate efficiently and safely. Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024