English

English

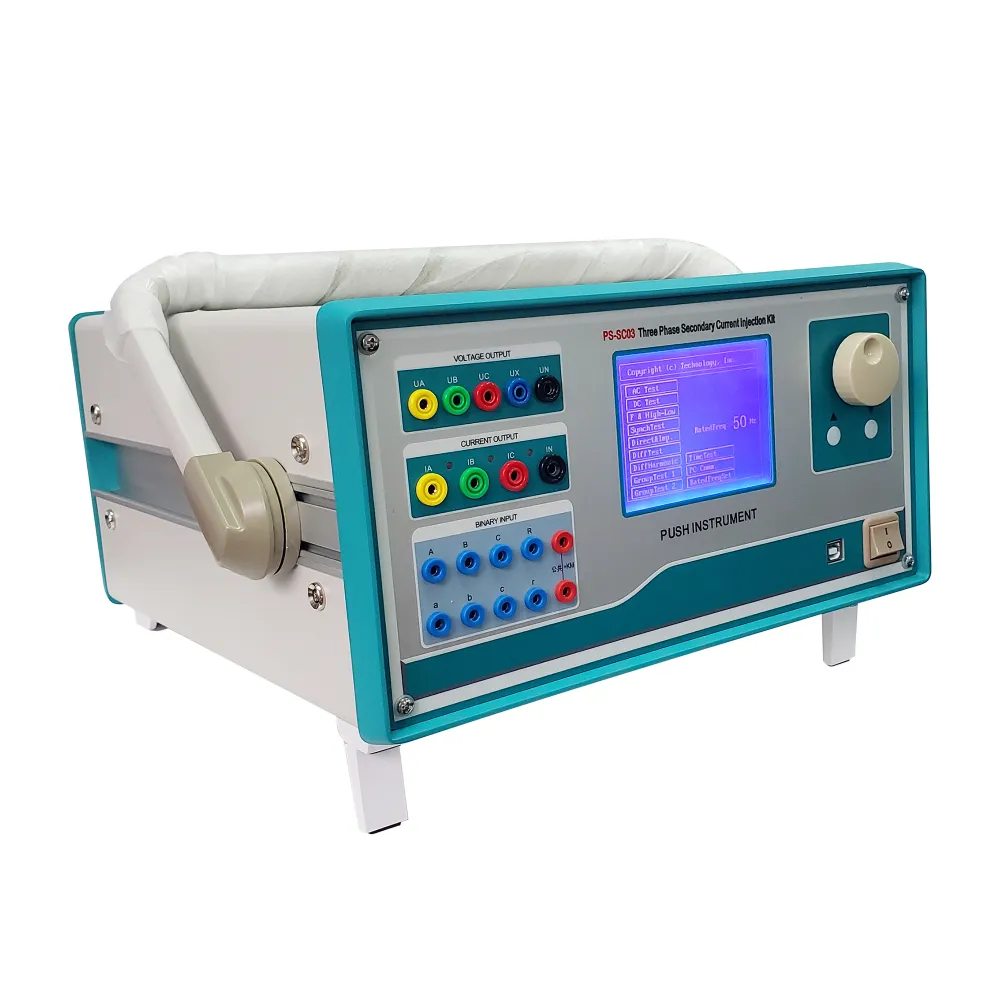

dielectric strength measurement

Dielectric Strength Measurement Understanding and Applications

Dielectric strength is a critical parameter used to evaluate the insulating properties of materials, particularly in electrical and electronic applications. It is defined as the maximum electric field that a material can withstand without experiencing failure, typically measured in volts per unit thickness (V/m or kV/mm). This property is essential for ensuring the safety and reliability of devices and systems that operate under high voltage conditions.

The Importance of Dielectric Strength Measurement

The dielectric strength of a material is vital in various applications, including power transmission lines, capacitors, transformers, and electrical insulators. A material with high dielectric strength can prevent breakdown under high voltage, reducing the risk of short circuits, equipment failure, and catastrophic electrical accidents. Therefore, accurately measuring dielectric strength is crucial for material selection and quality control in manufacturing processes.

Methods of Measuring Dielectric Strength

Several methods exist for measuring dielectric strength, each with its own advantages and limitations. The most common techniques include

1. AC Breakdown Method This method involves applying an alternating current (AC) voltage to a material until it breaks down. The voltage at which the breakdown occurs is recorded as the dielectric strength. This method can quickly provide results but is sensitive to environmental conditions such as temperature and humidity.

2. DC Breakdown Method Similar to the AC method, the DC breakdown method involves applying a direct current (DC) voltage. However, this method often yields higher breakdown voltages due to the absence of zero-voltage crossings, thus allowing the dielectric material to charge fully.

3. Impulse Voltage Method This technique employs a high-voltage impulse (a very fast rise time) to subject the material to a brief but intense electrical stress. This method simulates fault conditions and is particularly useful for testing the dielectric strength of materials used in outdoor applications.

Every measurement method requires careful preparation of specimen samples and controlled environmental conditions to ensure accurate and repeatable results. The choice of method often depends on the specific application and the characteristics of the materials being tested.

Factors Influencing Dielectric Strength

dielectric strength measurement

Several factors can influence the dielectric strength of a material

. These include- Material Composition Different materials have varying intrinsic dielectric properties. For instance, polymers, ceramics, and glasses all exhibit different dielectric strengths due to their molecular structures.

- Temperature and Humidity Environmental conditions significantly affect dielectric strength. Increased temperature typically lowers dielectric strength, while high humidity can lead to surface conductivity, further exacerbating breakdown risk.

- Thickness and Geometry The geometry and thickness of a dielectric material can affect its ability to withstand electric fields. Thinner materials may have lower dielectric strength due to a higher electric field intensity across them.

- Presence of Impurities Contaminants and defects within a material can create pathways for electrical breakdown, reducing the overall dielectric strength.

Applications of Dielectric Strength Measurement

Dielectric strength measurement finds applications across various sectors. In the electrical industry, it is used to test insulators for power lines and substations to ensure they can withstand operational stresses. In the automotive industry, high-voltage components in electric vehicles must be carefully tested to guarantee safety in the event of electrical faults.

In the consumer electronics realm, dielectric strength testing is crucial for devices that operate at high voltages, ensuring that the insulating components will not fail during operation. Furthermore, in the aerospace and military sectors, where equipment reliability is paramount, dielectric strength measurement plays a vital role in the development of advanced insulators and capacitors.

Conclusion

In summary, dielectric strength measurement is an essential process that ensures the safety and functionality of materials used in high-voltage applications. By understanding the methods, influencing factors, and various applications of this measurement, engineers and manufacturers can select appropriate materials and design more reliable electrical systems. As technology advances and materials become more complex, the significance of dielectric strength measurement will continue to grow, shaping the future of electrical engineering and electronics.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024