TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 10, 2025 10:54

Back to list

dielectric strength of transformer oil should be

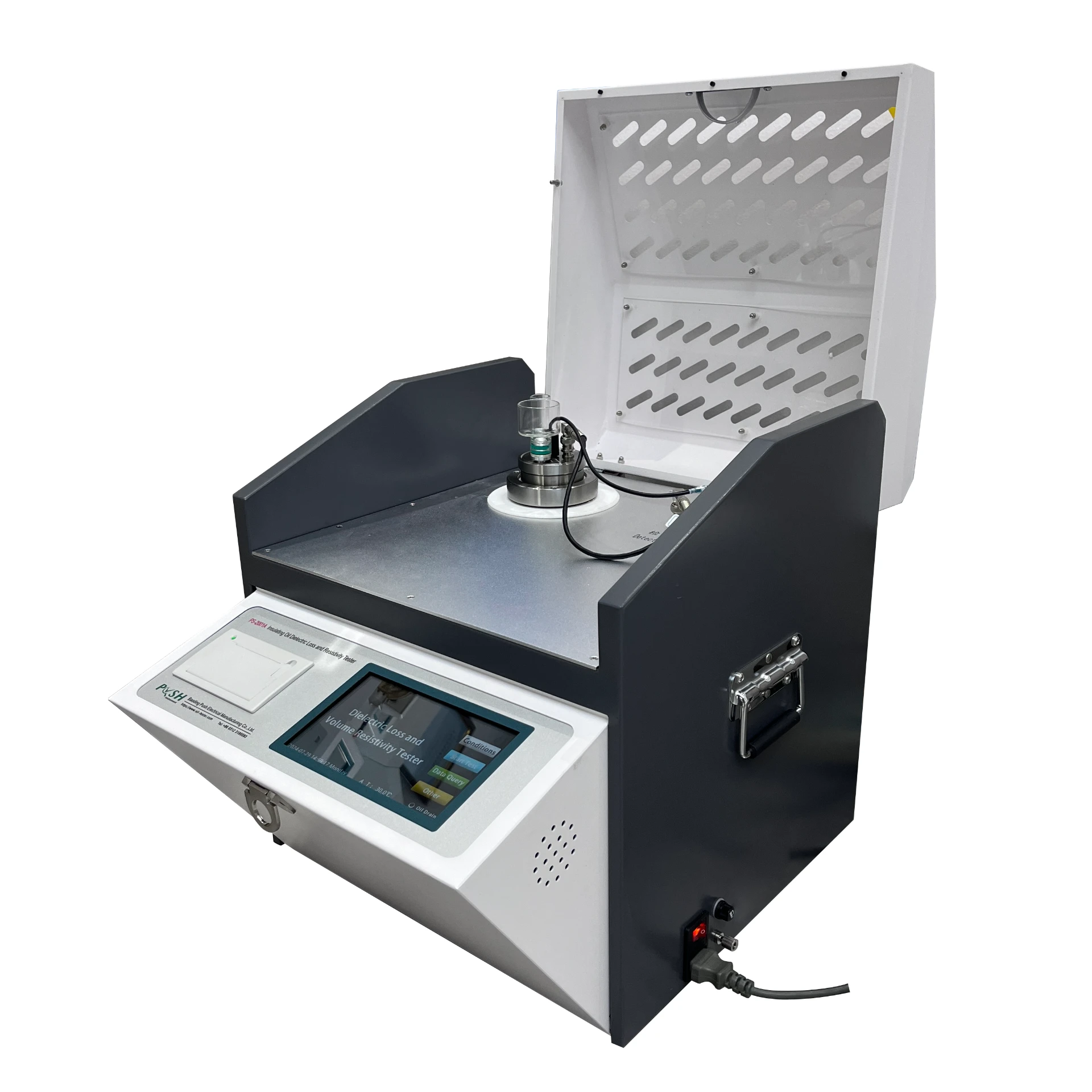

Understanding the dielectric strength of transformer oil is crucial for ensuring the longevity and reliability of transformers, which play an essential role in power distribution networks. Transformer oil is not only used as a coolant but also as an insulator, preventing electrical discharges. The dielectric strength of this oil determines its capacity to withstand electric stress without breaking down.

Furthermore, industry authorities highly recommend installing high-performance filtration systems. These systems work to continually remove particulate matter and water from the oil, thereby preserving its insulating properties. By investing in stepped-up maintenance protocols, including advanced filtration, operators can significantly enhance the reliability and safety of transformers. In the journey toward achieving optimal dielectric strength, understanding the role of additives is vital. While some additives are introduced to improve the thermal stability and oxidation resistance of transformer oil, their impact on dielectric properties is a subject of ongoing research. Collaboration with chemical specialists proves advantageous for operators seeking to balance oil longevity with robust insulating properties. Knowledge sharing from reputable authorities, such as IEEE or CIGRÉ, can bolster trustworthiness in the methodologies applied. Their guidelines and findings provide an authoritative benchmark for both oil manufacturers and transformer operators. In summary, the dielectric strength of transformer oil is a decisive factor in maintaining electrical integrity and efficiency. By embracing cutting-edge testing, purification, and monitoring solutions, industries can safeguard their transformer assets against premature failure. The fusion of experience-backed practices with authoritative insights forms the basis of an effective transformer oil management strategy, ensuring both operational continuity and safety in power systems.

Furthermore, industry authorities highly recommend installing high-performance filtration systems. These systems work to continually remove particulate matter and water from the oil, thereby preserving its insulating properties. By investing in stepped-up maintenance protocols, including advanced filtration, operators can significantly enhance the reliability and safety of transformers. In the journey toward achieving optimal dielectric strength, understanding the role of additives is vital. While some additives are introduced to improve the thermal stability and oxidation resistance of transformer oil, their impact on dielectric properties is a subject of ongoing research. Collaboration with chemical specialists proves advantageous for operators seeking to balance oil longevity with robust insulating properties. Knowledge sharing from reputable authorities, such as IEEE or CIGRÉ, can bolster trustworthiness in the methodologies applied. Their guidelines and findings provide an authoritative benchmark for both oil manufacturers and transformer operators. In summary, the dielectric strength of transformer oil is a decisive factor in maintaining electrical integrity and efficiency. By embracing cutting-edge testing, purification, and monitoring solutions, industries can safeguard their transformer assets against premature failure. The fusion of experience-backed practices with authoritative insights forms the basis of an effective transformer oil management strategy, ensuring both operational continuity and safety in power systems.

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024