English

English

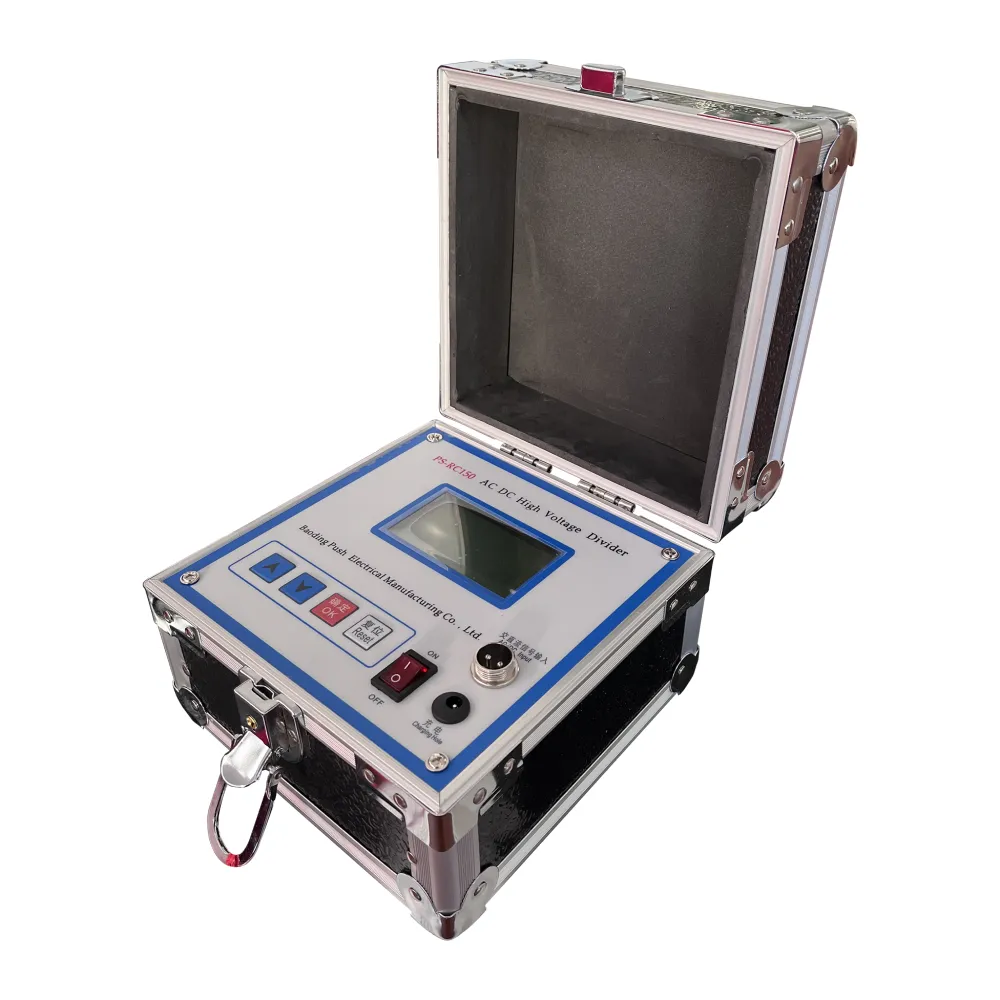

dielectric withstand tester

Understanding Dielectric Withstand Testers Ensuring Electrical Safety

When it comes to electrical equipment, safety is paramount. The dielectric withstand tester, also known as a hi-pot tester or insulation tester, plays a crucial role in ensuring that electrical systems and devices operate safely and effectively. This device is designed to verify that insulation materials can withstand high voltage without breakdown, thereby protecting both users and equipment.

What is a Dielectric Withstand Tester?

A dielectric withstand tester applies a high voltage to the electrical insulation of equipment to evaluate its ability to resist electrical breakdown. Typically, this involves subjecting the insulation to voltages higher than the normal operating conditions to ensure that it can handle unexpected surges. This testing is essential for various electrical devices, including transformers, circuit breakers, and motors.

The tester usually provides a controlled environment where the voltage can be incrementally increased until it reaches a predetermined level. The dielectric withstand tester measures the current flow during the test, indicating whether the insulation is adequate. If the insulation fails, it means the current exceeds a set threshold, suggesting potential risks of electrical shock or fire hazards.

Importance of Dielectric Testing

Dielectric testing is crucial for many reasons

1. Safety Assurance The primary goal of dielectric withstand testing is to ensure the safety of electrical appliances. By confirming that the insulation can withstand higher voltages, manufacturers can significantly reduce the risk of electric shock and equipment failure.

2. Regulatory Compliance Many industries are bound by strict regulations regarding electrical safety. Regular testing of insulation can help companies comply with international standards, such as IEC, UL, and ANSI, ensuring that their products meet stringent safety requirements.

3. Quality Control By integrating dielectric testing into the manufacturing process, companies can monitor the quality of their products. Testing helps identify insulation defects early, reducing the likelihood of recalls or failure in the field.

4. Preventive Maintenance For existing electrical systems, regular dielectric testing can serve as a preventive measure. Identifying and addressing insulation deterioration can prolong equipment life and improve reliability, thereby reducing maintenance costs and downtime.

Types of Dielectric Testing

dielectric withstand tester

There are several methods for conducting dielectric testing, including

- AC Dielectric Withstand Testing This method uses alternating current and is most common in testing electrical insulation. It effectively simulates typical operating conditions and helps identify insulation weaknesses.

- DC Dielectric Withstand Testing This method applies direct current for testing. It is often used for equipment that will be subjected to DC voltage in operation, such as in some photovoltaic systems.

- Insulation Resistance Testing This test measures the resistance of the insulation material itself instead of applying high voltage. It can provide valuable insight into the condition of the insulation without stressing it with high voltages.

Choosing the Right Tester

When selecting a dielectric withstand tester, it is essential to consider the following

- Voltage Range Ensure that the tester can provide the necessary voltage for the specific applications you require, ranging from a few hundred volts to several kilovolts.

- Current Measurement Look for testers that accurately measure the leakage current during the test, which is crucial for determining insulation integrity.

- Portability In many cases, the ability to easily transport the tester to different job sites can be advantageous for field testing.

- Safety Features Select testers that include safety features such as automatic shutdown and input protection to safeguard both the operator and the equipment.

Conclusion

Dielectric withstand testers are an indispensable tool in the electrical industry. By ensuring that insulation can withstand high voltage without failure, these testers play a vital role in safeguarding users and equipment alike. As technology continues to advance, the importance of this testing will only grow, making it a critical component of any comprehensive electrical safety program. Regular testing not only assures compliance with safety standards but also enhances the longevity and reliability of electrical devices.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024