English

English

digital ir tester

Exploring Digital IR Testers Revolutionizing Infrared Testing

In recent years, the advancements in technology have transformed the way we approach various testing methodologies, and one of the standout innovations in this field is the Digital Infrared (IR) Tester. These devices have revolutionized infrared testing, offering precision, efficiency, and ease of use that significantly enhances the testing process in various industries, including electrical engineering, building inspections, and manufacturing.

Understanding Digital IR Testers

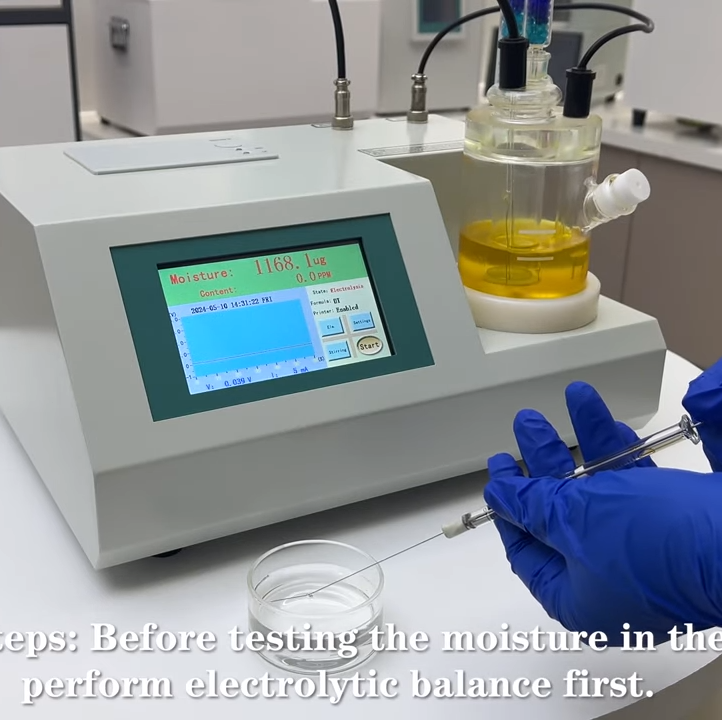

Digital IR testers are sophisticated instruments designed to measure temperature without direct contact. Utilizing infrared technology, these testers detect the thermal radiation emitted by objects and convert it into temperature readings displayed on a digital screen. This feature makes IR testers a preferred choice for many professionals who require accurate temperature measurements in situations where traditional contact methods may be impractical or unsafe.

Key Features and Benefits

One of the key features of digital IR testers is their ability to provide instant readings. Unlike conventional thermometers that may take time to stabilize, digital IR testers offer immediate feedback, allowing operators to make swift decisions. This speed is particularly beneficial in critical situations, such as electrical inspections where overheating components can pose safety risks.

Moreover, many digital IR testers come equipped with advanced features such as emissivity adjustments, laser pointers for accuracy, and the capability to log data. Adjusting emissivity is crucial when measuring the temperature of different materials, as various surfaces emit infrared radiation differently. The inclusion of laser pointers helps users aim precisely, ensuring they measure the correct target. Data logging features allow for the collection and storage of measurements over time, facilitating analysis and comparison, which is essential in maintaining consistent operational standards and compliance in various fields.

digital ir tester

Applications Across Industries

Digital IR testers have diverse applications across several sectors. In electrical engineering, they are instrumental in preventive maintenance, aiding technicians in identifying overheating components, loose connections, and potential failure points before they become significant problems. This proactive approach reduces downtime and maintenance costs, ultimately enhancing system reliability.

In the construction and building inspection industry, digital IR testers are valuable for identifying insulation deficiencies, air leaks, and moisture issues. By detecting temperature variations on building surfaces, inspectors can pinpoint problem areas without the need for invasive methods. This capability not only saves time but also minimizes disruption during inspections, making it an efficient tool for builders and inspectors alike.

Additionally, in the manufacturing sector, digital IR testers play a crucial role in quality control. They ensure that products meet specific temperature requirements during the production process, preventing defects and ensuring product safety and efficacy. This application is particularly vital in industries such as food processing and pharmaceuticals, where strict temperature regulations are paramount.

Conclusion

Digital IR testers represent a significant advancement in the realm of temperature measurement and testing. Their ability to deliver fast, accurate, and contactless measurements has made them essential tools across various industries. As technology continues to evolve, we can expect further enhancements in the capabilities of digital IR testers, paving the way for even more efficient and effective testing methodologies. Embracing such innovations not only streamlines operations but also plays a crucial role in ensuring safety and compliance in our increasingly complex industrial landscape.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024