English

English

Double Distillation Unit for High-Purity Chemical Separation

Double Distillation Unit An Overview

A double distillation unit is an essential apparatus in various industrial processes, particularly in the fields of chemical engineering and petrochemical refining. This unit is designed to enhance the purity of liquids through a two-step distillation process, which effectively removes impurities, volatile compounds, and other unwanted substances. By employing this method, industries can achieve higher yields of desired products and ensure that the final output meets stringent quality standards.

The operation of a double distillation unit involves two distinct phases the first distillation and the second distillation. During the first distillation, the feed mixture is heated in a distillation column, where it is separated based on the different boiling points of its components. As the mixture is heated, the more volatile components vaporize and are drawn off, while the less volatile components remain in the liquid phase.

The vapor collected from the first distillation is then subjected to a second distillation process. In this phase, the vapor undergoes further purification. The second distillation column is operated under controlled conditions, enabling a more refined separation of components. This step is crucial for removing any remaining impurities that may have passed through the first distillation. By the end of the second distillation, the final product obtained is of significantly higher purity than the initial feed.

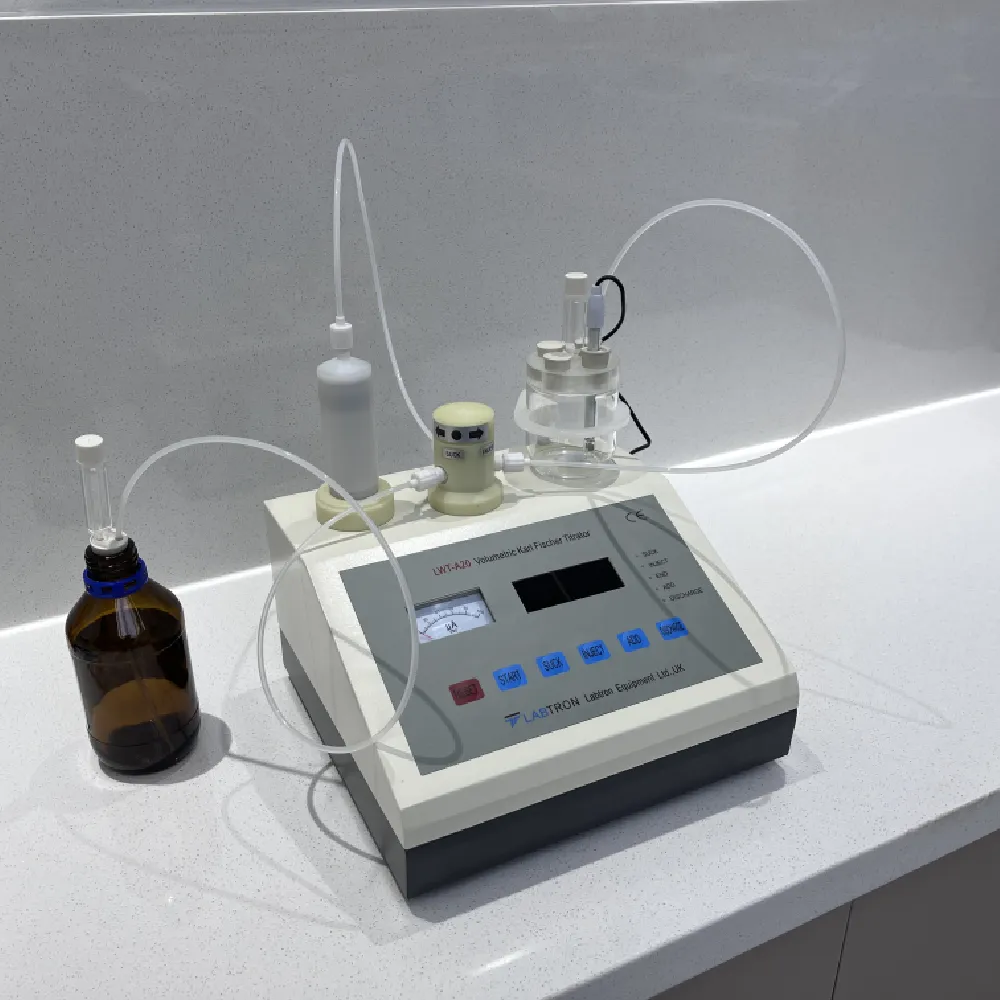

double distillation unit

Double distillation units are widely used in various applications, including the production of solvents, essential oils, and high-purity chemicals. In the petrochemical industry, they play a vital role in refining crude oil into usable products such as gasoline, diesel, and kerosene. The ability to produce high-purity outputs makes double distillation units invaluable in pharmaceuticals, where purity is paramount for efficacy and safety.

In addition to their effectiveness, double distillation units are praised for their energy efficiency and cost-effectiveness. While the initial investment in such equipment can be substantial, the long-term benefits in terms of product yield and quality often justify the expense. Moreover, advancements in technology continue to enhance the performance of these units, making them more adaptable and efficient for various industrial needs.

In conclusion, the double distillation unit is a cornerstone of modern chemical processing, providing a crucial method for achieving high purity levels in a wide range of products. Its significance in various industries not only highlights its operational efficiency but also underscores the ongoing advancements in distillation technologies.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024