English

English

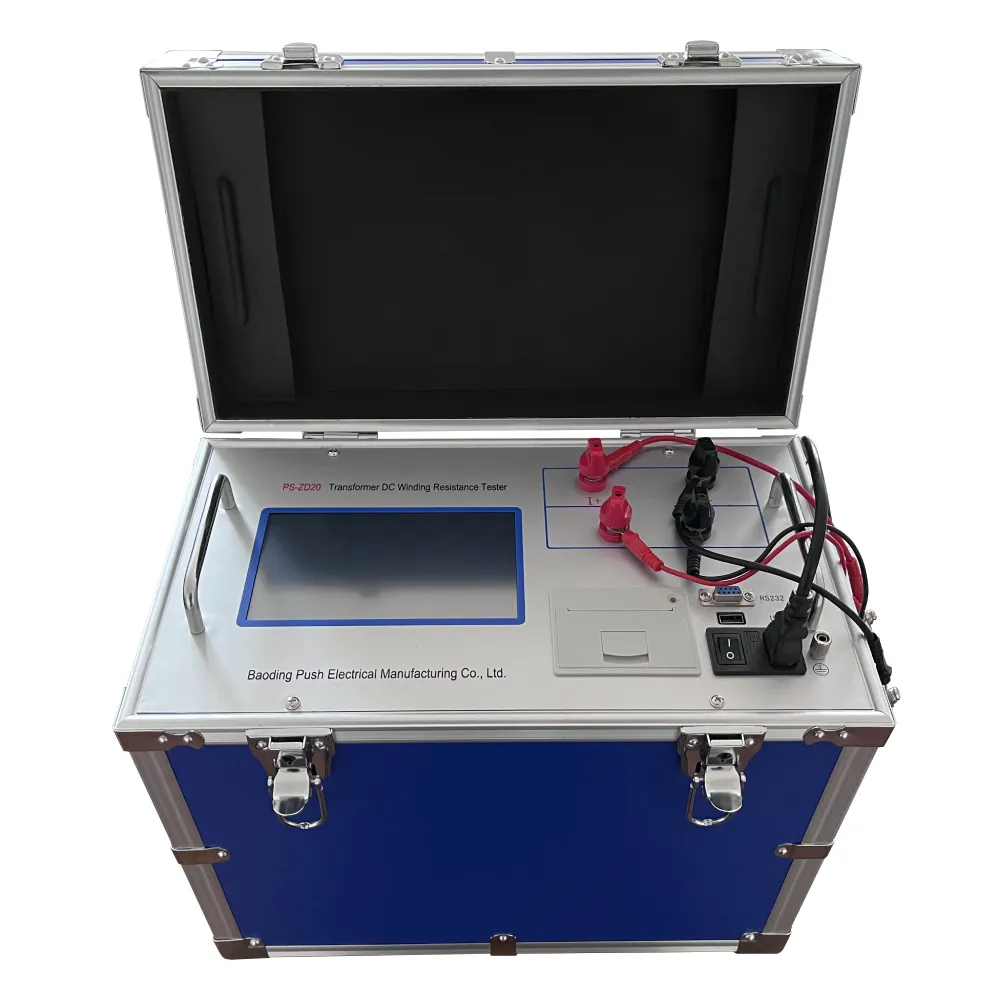

Enhanced Transformer Ohmmeter for Accurate Resistance Measurements in Electrical Applications

Understanding the Transformer Ohmmeter A Comprehensive Guide

In the world of electrical testing and maintenance, precision is essential. One tool that stands out in its ability to measure resistance in electrical equipment is the transformer ohmmeter. This specialized device is crucial for various applications, particularly in the power generation and distribution industry, where it ensures the integrity and functionality of transformers.

What is a Transformer Ohmmeter?

A transformer ohmmeter is a type of resistance measurement device designed specifically for testing the windings of transformers. It is capable of applying a high current to measure low resistance values accurately, which is vital for ensuring that the transformer operates efficiently and safely. This tool helps identify issues like winding faults or short-circuits, which can lead to catastrophic failures if left undetected.

How Does It Work?

The transformer ohmmeter operates by passing a known current through the winding of the transformer and measuring the corresponding voltage drop. By applying Ohm’s Law (V = I × R), the device calculates the resistance (R) by rearranging the formula to R = V/I. This method allows for precise measurements even in winding configurations where resistance values are typically low, making it indispensable for electrical engineers and technicians.

Most transformer ohmmeters are designed to output high test currents, often in the range of 1 A to 100 A, to ensure accurate readings for the low resistance typical in transformer windings

. This distinguishes them from regular ohmmeters, which are not suitable for such low-resistance applications.Applications

Transformer ohmmeters are used extensively in the maintenance and testing of transformers. Some common applications include

transformer ohmmeter

1. Winding Resistance Testing Ensuring that the transformer windings are operating as designed without undue resistance, which can cause overheating and reduce efficiency.

2. Connection Testing Checking the integrity of connections and ensuring there are no breaks or faults in the winding circuits.

3. Quality Control During the manufacturing process, transformers are tested to ensure their windings meet design specifications before being placed into service.

4. Routine Maintenance Regular testing of transformers in operation to catch and address issues before they lead to significant failures, helping maintain system reliability.

Benefits

Using a transformer ohmmeter offers several benefits. Firstly, it enhances safety by identifying faults before they escalate into dangerous failures. Secondly, periodic testing can extend the lifespan of transformers by ensuring they're maintained under optimal conditions. Additionally, the insights gained from these tests can significantly reduce downtime, as they enable electrical engineers to schedule maintenance proactively instead of reactively.

Conclusion

In conclusion, the transformer ohmmeter is an essential tool in electrical maintenance, particularly for those involved with transformers. Its ability to measure low resistance accurately makes it invaluable for diagnosing potential issues before they develop into serious problems. With the right equipment and regular testing, organizations can ensure that their electrical systems remain reliable, safe, and efficient, solidifying the importance of transformer ohmmeters in the realm of electrical engineering and maintenance. As technology continues to advance, staying updated on the capabilities and proper usage of this device will be crucial for professionals in the field.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024