English

English

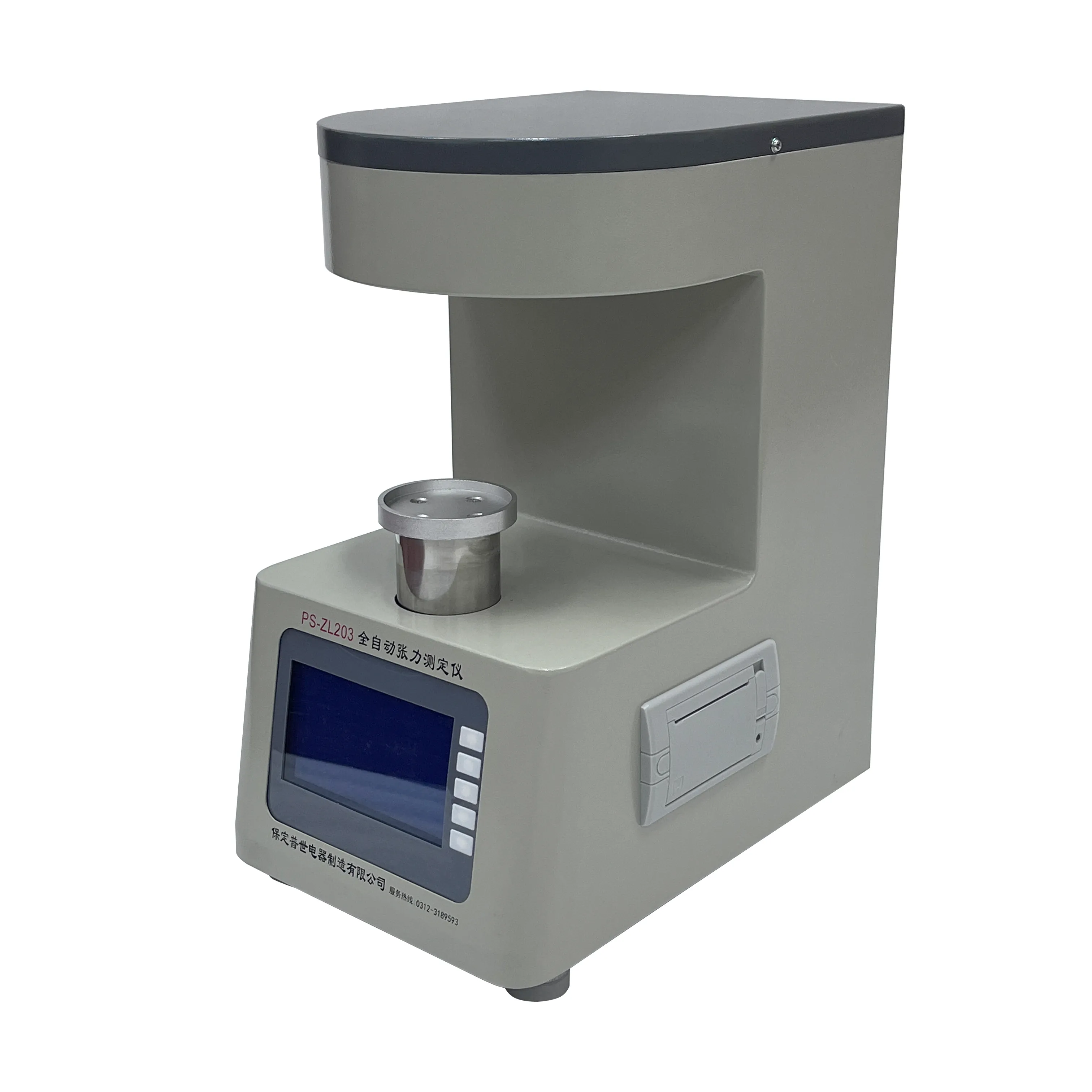

Essential Equipment for Petroleum Laboratory Analysis and Testing

The Importance of Petroleum Laboratory Equipment in Industry

Petroleum, one of the most critical resources in modern industry, is extracted, processed, and refined using a range of advanced technologies. Integral to these processes is petroleum laboratory equipment, which plays a pivotal role in ensuring the accuracy, efficiency, and safety of petroleum-related operations. This equipment is essential for quality control, research and development, and compliance with environmental regulations.

Types of Petroleum Laboratory Equipment

Petroleum laboratories utilize various types of equipment designed to analyze and test petroleum products. Among the most common are

1. Viscometers These devices measure the viscosity of petroleum products, which is crucial for understanding how they will flow under different temperatures and pressures. This information is vital for refining processes and ensuring the proper operation of pipelines.

2. Gas Chromatographs Gas chromatography is employed to separate and analyze compounds in liquid and gaseous samples. In the petroleum industry, it is often used to determine the composition of crude oil and natural gas, helping companies understand the quality and potential yield of their resources.

3. Flash Point Testers The flash point is the lowest temperature at which vapors of a volatile substance can ignite. Knowing this information is essential for safety in storage and transportation. Flash point testers are used to ensure that petroleum products meet safety standards.

4. Density Meters These instruments measure the density of petroleum products, which can affect their pricing and performance in various applications. Density measurements help in characterizing crude oil and evaluating its commercial value.

5. Sample Cleaners and Purification Systems Contaminated samples can result in inaccurate test results. Accordingly, sample cleaning equipment is vital in preparing petroleum samples for analysis while maintaining the integrity of the sample.

petroleum laboratory equipment

Quality Control and Compliance

In the petroleum industry, adhering to quality control standards and regulations is paramount. Laboratory equipment facilitates the rigorous testing of products to ensure they meet industry norms. This involves checking for impurities, testing performance under various conditions, and verifying chemical composition.

Additionally, compliance with environmental regulations is increasingly crucial due to global concerns about pollution and climate change. Equipment that tests for volatile organic compounds (VOCs) and other harmful emissions assists companies in adhering to government regulations while also ensuring safety for employees and surrounding communities.

Advancements in Laboratory Technology

The petroleum sector has seen significant advancements in laboratory equipment technology. Automation and digital technologies have streamlined processes, improving both efficiency and accuracy. For example, automated sampling systems can collect and prepare samples with minimal human intervention, reducing potential errors and enhancing safety.

Moreover, artificial intelligence and machine learning are beginning to play a role in data analysis within petroleum laboratories. These technologies can help predict outcomes based on historical data, optimize processes, and improve decision-making in resource management.

Conclusion

In conclusion, petroleum laboratory equipment is an indispensable part of the petroleum industry. It facilitates essential functions like quality control, compliance with safety standards, and the efficient processing of petroleum products. As technology continues to advance, the role of these laboratories and their equipment will become increasingly sophisticated, promoting sustainability and safety within the industry. The future of petroleum will demand innovative approaches to exploration, extraction, and refinement, and the backbone of these efforts will be the lab equipment used to support them.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024