English

English

Essential Equipment for Testing Protection Relays in Electrical Systems and Ensuring Operational Reliability

Protection Relay Testing Equipment Ensuring Electrical Safety and Reliability

Protection relay testing equipment plays a vital role in the electrical power industry, serving as a critical tool for ensuring the safe and reliable operation of power systems. Protection relays are designed to detect abnormal electrical conditions and initiate circuit interruptions to prevent damage to equipment and safeguard personnel. However, these relays must be regularly tested and maintained to ensure their proper functionality. This is where protection relay testing equipment comes into play.

Understanding Protection Relays

Protection relays are devices that monitor electrical parameters such as current, voltage, frequency, and phase angle. They analyze these parameters continuously, and when they detect anomalies—like overcurrent, under-voltage, or phase imbalances—they activate circuit breakers to isolate the affected system. This real-time monitoring is essential for preventing equipment damage, minimizing downtime, and ensuring the safety of both facilities and personnel.

The Importance of Testing

Over time, protection relays may experience wear, develop faults, or become misconfigured, leading to a potential failure in their function. Consequently, routine testing of these devices is paramount. Testing verifies that the relays operate correctly under various conditions and that their settings match the intended protection schemes.

Failure to conduct regular testing can have serious repercussions. Inadequate protection may result in catastrophic equipment failures, leading to costly repairs and operational downtime. More critically, it can jeopardize safety, potentially resulting in accidents and injuries.

Types of Protection Relay Testing Equipment

The market offers various types of protection relay testing equipment, ranging from simple devices for field testing to sophisticated software solutions for comprehensive system analysis

. Common types include1. Relay Test Kits These compact and portable devices typically come with an array of testing functionalities. They allow technicians to simulate various fault conditions and observe how the relays respond. Popular features include injection testing, where a defined current or voltage is sent to the relay to check its operational thresholds.

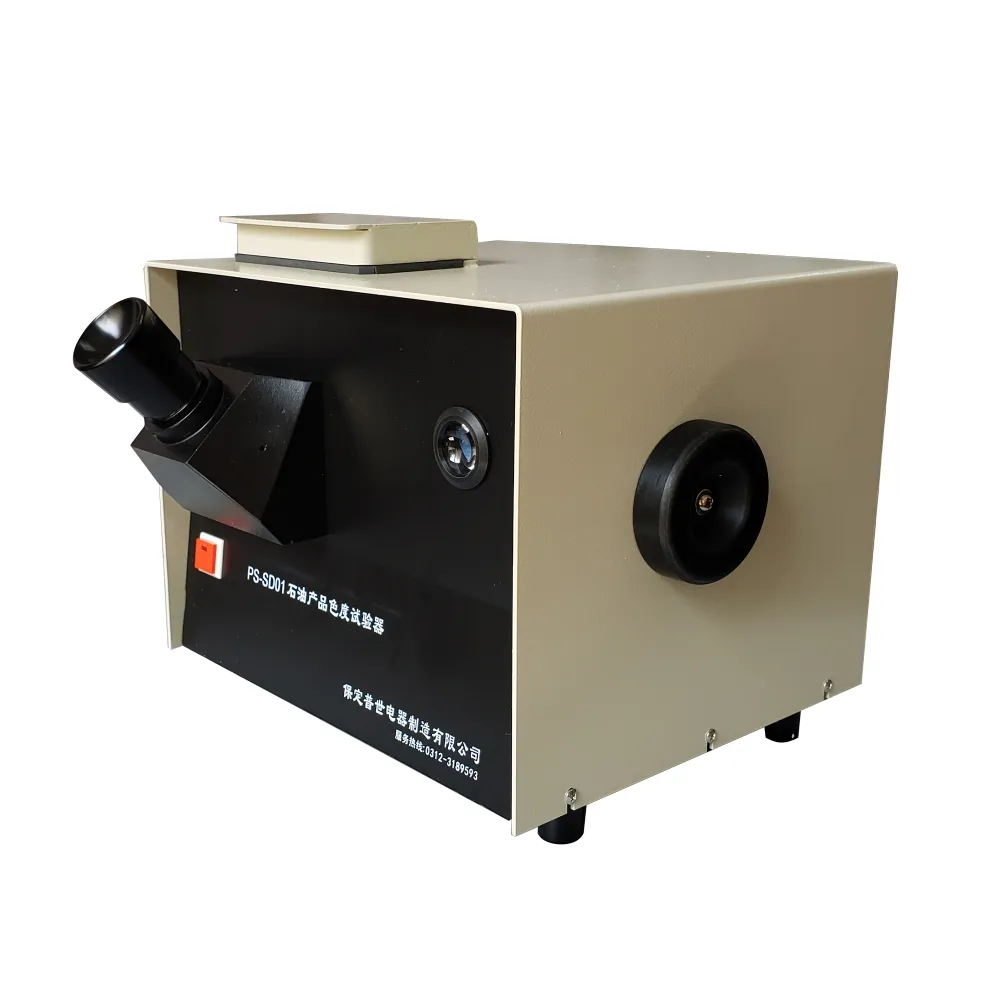

protection relay testing equipment

2. Multi-Function Testers Designed for versatility, these devices can test various types of relays, including electromechanical, solid-state, and digital models. They often incorporate advanced features like automated testing sequences, real-time monitoring, and data logging for analysis.

3. PC-Based Software Solutions These tools enable users to conduct detailed analyses of relay performance and settings through computer interfaces. They can generate comprehensive reports and graphically represent testing outcomes, making it easier for engineers to identify trends or anomalies.

Best Practices for Testing

To maintain the reliability of protection relays, adherence to best practices during testing is essential. Key considerations include

- Regular Testing Schedule Establish and follow a routine testing schedule based on industry standards and specific operational needs. - Proper Training Ensure that personnel conducting the tests are adequately trained and familiar with both the equipment and the relays being tested.

- Documentation Maintain comprehensive records of testing procedures, results, and maintenance performed to create a historical overview that can aid in trend analysis and future system enhancements.

- Calibration Regularly calibrate testing equipment to ensure accuracy and reliability during testing processes.

Conclusion

Protection relay testing equipment is an indispensable element of electrical safety management. By ensuring that these critical devices operate correctly, organizations can mitigate risks to personnel and property, enhance equipment reliability, and maintain uninterrupted operations. Ultimately, a commitment to regular testing not only fulfills regulatory requirements but also contributes to a culture of safety and efficiency in the power sector.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024