English

English

Essential Guide to Understanding DC Hipot Testers for Electrical Safety Testing Applications

Understanding DC Hipot Testers Essential Tools for Electrical Safety Testing

In the field of electrical engineering, ensuring the safety and reliability of electrical insulation is paramount. One of the key instruments used for this purpose is the DC Hipot tester, an essential device that plays a crucial role in electrical testing, especially in high-voltage applications. This article will delve into the purpose, functionality, and importance of DC Hipot testers in maintaining electrical safety standards.

What is a DC Hipot Tester?

A DC Hipot (High Potential) tester is an electrical testing device designed to apply a high-voltage direct current (DC) to an insulation system. The primary purpose of this testing equipment is to verify the integrity of insulation used in electrical devices, cables, transformers, and other components. By using DC voltage, the Hipot tester can simulate stress conditions that the insulation might encounter in real-life operational environments.

How Does it Work?

The DC Hipot tester functions by generating a high voltage that is applied to the insulation under test while monitoring the leakage current. The test involves connecting the high-voltage output from the tester to one conductor of the insulation system, while the other conductor is grounded. The voltage is gradually increased to a predetermined level, allowing the tester to evaluate whether the insulation can withstand the applied voltage without breakdown.

During the test, the leakage current is carefully monitored. A small amount of leakage current is normal; however, if the leakage current exceeds a specified limit, it indicates a failure in the insulation, such as degradation or deterioration due to aging, moisture, or physical damage. The tester typically features safety mechanisms to ensure that the operator and the equipment are protected during testing, as high voltage can pose serious hazards.

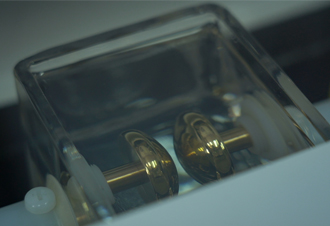

dc hipot tester

Why is DC Hipot Testing Important?

1. Safety Assurance Electrical insulation failure can lead to catastrophic outcomes, including electrical shock, fire hazards, and equipment damage. DC Hipot testing provides a reliable method to evaluate the integrity of insulation, ensuring that equipment operates safely under high voltage conditions.

2. Quality Control For manufacturers of electrical components, performing DC Hipot tests is essential for quality assurance. Testing ensures that their products meet industry standards and can withstand the rigors of real-world application.

3. Preventive Maintenance Regular DC Hipot testing is a vital part of preventive maintenance programs for industrial facilities. By identifying potential insulation failures before they lead to equipment malfunction, organizations can reduce downtime and repair costs.

4. Regulatory Compliance Many industries are subject to rigorous safety regulations. Conducting DC Hipot tests helps organizations comply with these regulations, demonstrating a commitment to safety and operational excellence.

Conclusion

The DC Hipot tester stands as a cornerstone in electrical safety testing, offering invaluable insights into the condition of insulation systems. Through meticulous testing, it helps to prevent safety incidents and ensures that electrical equipment performs reliably under high voltage conditions. As technology continues to evolve, the importance of DC Hipot testers will only grow, reinforcing their role as essential tools in the maintenance and certification of electrical safety across various industries. Whether for manufacturing, maintenance, or compliance, investing in reliable DC Hipot testing is crucial for safeguarding both personnel and equipment in the ever-evolving landscape of electrical engineering.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024