English

English

Evaluation of Interfacial Tension in Transformer Oil Using Standard Testing Methods and Procedures

Interfacial Tension Test of Transformer Oil An Essential Diagnostic Tool

Transformer oil, commonly referred to as insulating oil, plays a critical role in the efficient operation and longevity of transformers. Its primary functions include insulation of live parts and heat dissipation. Over time, however, transformer oil can degrade due to thermal stress, oxidation, and contamination, compromising its performance. One key parameter in assessing the quality of transformer oil is interfacial tension (IFT), which serves as an important indicator of the oil's condition and its ability to perform effectively.

Interfacial tension is defined as the force per unit length existing at the interface of two immiscible fluids. In the case of transformer oil, this typically pertains to the interface between the oil and water. The measurement of interfacial tension gives critical insights into the presence of polar contaminants, such as moisture, acids, or soluble polar compounds, which can enter the oil during operation. These contaminants can significantly affect the electrical insulating properties of the oil and reduce its overall performance.

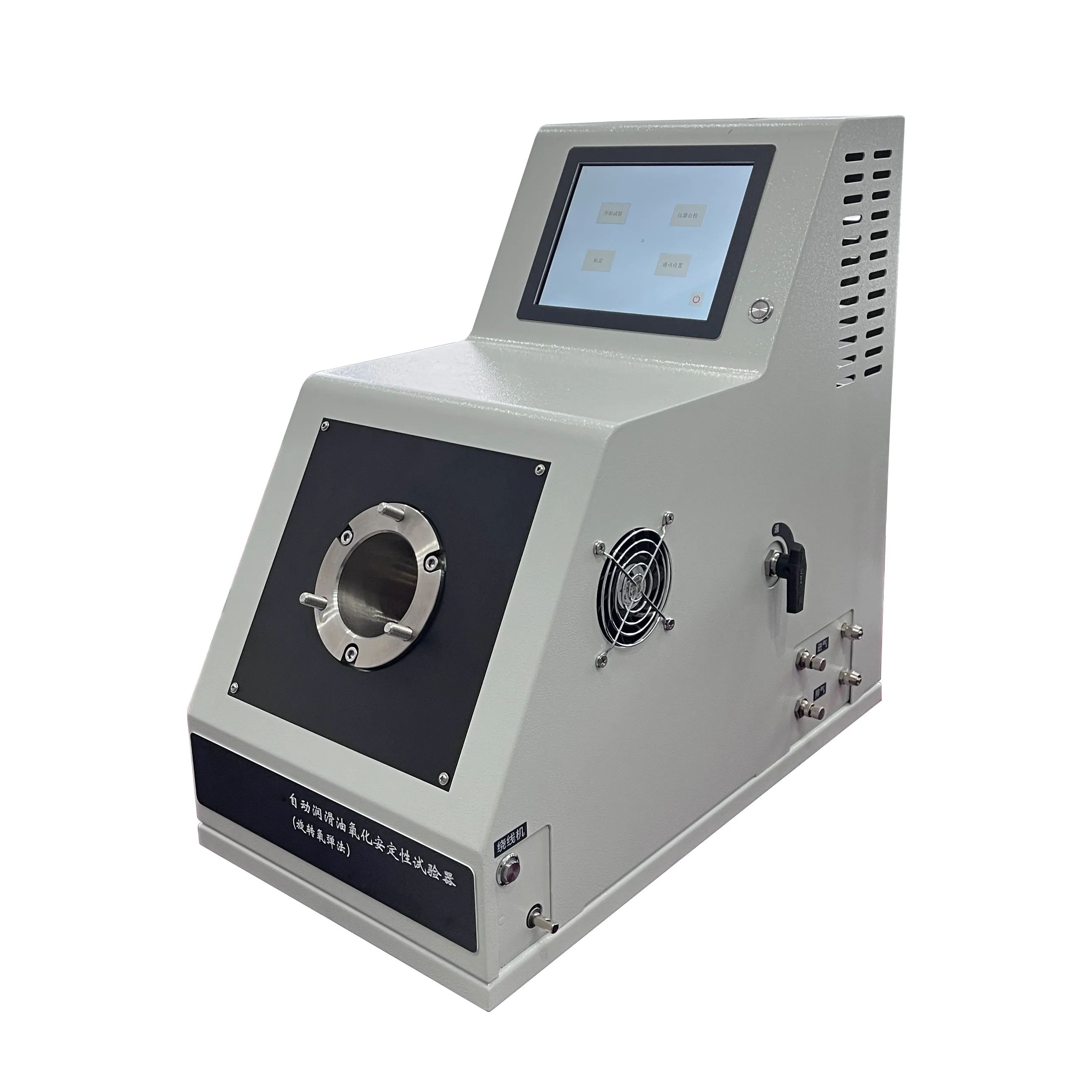

The interfacial tension test involves placing a drop of transformer oil on the surface of water and measuring the force exerted by the oil at the interface. This measurement can be conducted using a tensiometer or similar apparatus. A higher interfacial tension value generally suggests that the oil is free from polar contaminants, whereas a lower value indicates potential degradation or contamination. Typically, values above 30 mN/m are considered acceptable, while values below this threshold may trigger further examination and remediation efforts.

interfacial tension test of transformer oil

Regular interfacial tension testing forms part of a comprehensive oil analysis program and is crucial for predictive maintenance strategies in transformer management. It allows utilities and maintenance teams to monitor the condition of transformer oil continuously, aiding in the early detection of problems that can lead to transformer failure. As such, IFT tests can help prevent costly outages, reduce unscheduled maintenance, and extend the lifespan of transformer equipment.

Moreover, assessments of interfacial tension should not be conducted in isolation. They should be combined with other analyses, such as dielectric strength, dissolved gas analysis, and moisture content determination. This multifaceted approach provides a more holistic understanding of the transformer oil's health, enabling informed decisions regarding oil replacement or treatment.

In summary, the interfacial tension test of transformer oil is an essential diagnostic tool that assists electrical engineers and maintenance personnel in ensuring the reliability and safety of transformer operations. By understanding the dynamics of interfacial tension, stakeholders can take appropriate actions to maintain transformer integrity, optimize performance, and enhance system reliability. As the demand for electrical power continues to grow, the importance of effective transformer oil management will only increase, making regular IFT testing not just a routine task, but a fundamental aspect of power system maintenance.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024