English

English

Exploring the Benefits and Applications of Tan Delta Testing Kits in Electrical Insulation Diagnostics

Understanding the Tan Delta Test Kit A Key Tool for Electrical Insulation Testing

In the realm of electrical engineering, the integrity of insulation materials is paramount to ensuring the safety and reliability of electrical systems. One of the most effective methods for assessing the quality of insulation is the Tan Delta test, also known as the Power Factor test. This article delves into the essentials of the Tan Delta test kit, its principles, applications, and significance in industrial settings.

What is the Tan Delta Test?

The Tan Delta test measures the power factor of an insulating material, providing a quantitative assessment of its quality. The term Tan Delta refers to the tangent of the loss angle (delta), which represents the ratio of the resistive current (leakage current) to the reactive current (capacitive current) in an insulating material. A low value indicates good insulation, while a high value signals potential issues such as aging, moisture ingress, or contamination.

How Does a Tan Delta Test Kit Work?

A Tan Delta test kit typically comprises a high-voltage power supply, a diagnostic unit, and measurement probes. The process involves applying an alternating current (AC) to the insulation material under test. The kit then measures the phase angle difference between the current and the applied voltage. This data is used to calculate the Tan Delta value, which is then compared to established standards to determine the condition of the insulation.

Components of a Tan Delta Test Kit

1. High-Voltage Power Source This component generates the required AC voltage to simulate operating conditions for the insulation material.

2. Measurement Unit The heart of the test kit, the measurement unit analyzes the current and voltage signals to determine the phase angle and calculate the Tan Delta value.

3. Probes High-voltage probes are used to safely conduct the test on various insulating materials, including cables, transformers, and circuit breakers.

4. Software Interface Many modern Tan Delta test kits come equipped with software that allows for data analysis, trends, and reporting, facilitating better decision-making.

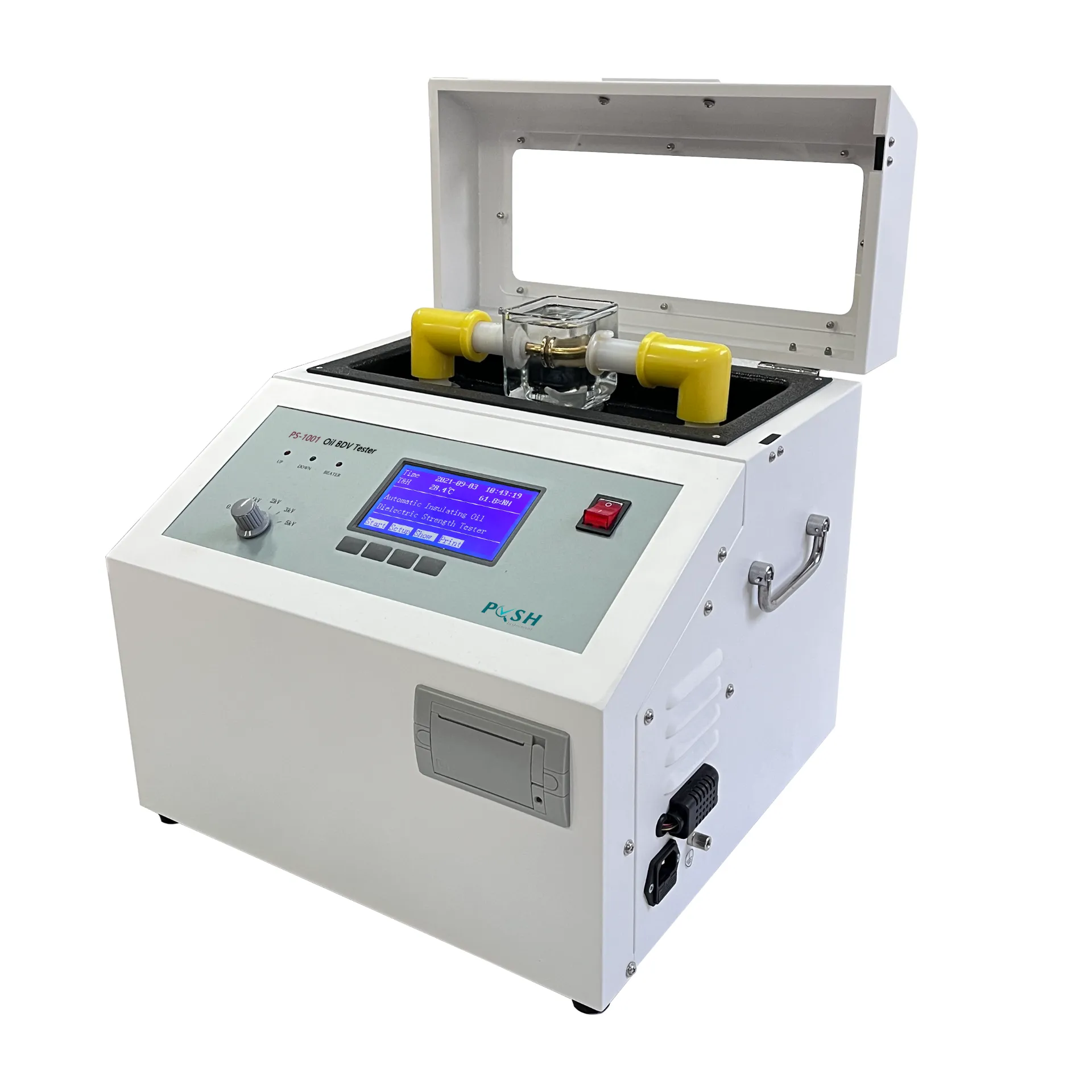

tan delta test kit

Applications of Tan Delta Testing

The Tan Delta test is widely used in various industries, including

- Power Generation In power plants, Tan Delta testing is essential for ensuring the reliability of transformers and cables, which are critical for transferring electricity.

- Utilities and Transmission Utility companies use Tan Delta tests to assess the health of insulation in high-voltage cables and substations, helping avoid unexpected outages.

- Manufacturing In manufacturing plants, Tan Delta testing helps in maintaining the insulation of motors and generators, thereby ensuring operational efficiency.

- Maintenance Regular testing enables predictive maintenance, allowing companies to schedule repairs before serious failures occur.

Importance of Tan Delta Testing

The significance of Tan Delta testing cannot be overstated. It helps prevent catastrophic failures that can lead to costly downtime and safety hazards. By identifying insulation weaknesses early, companies can implement corrective measures, ultimately ensuring operational continuity and safety.

Furthermore, with increasing regulatory pressures on industries to monitor and maintain equipment properly, the Tan Delta test provides a straightforward and effective solution to meet compliance requirements.

Conclusion

The Tan Delta test kit is an invaluable tool in the arsenal of electrical engineers and maintenance professionals. By providing insights into the condition of insulation materials, it helps safeguard electrical systems against failures. As technology advances, these kits continue to evolve, offering enhanced features that make testing more accurate and reliable. Investing in quality Tan Delta testing not only protects assets but also promotes a culture of safety and efficiency in electrical operations.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024