English

English

Exploring the Importance and Functionality of AC Dielectric Testing Equipment in Electrical Insulation Evaluation

Understanding AC Dielectric Testers Essential Tools for Insulation Testing

An AC dielectric tester is a crucial device used primarily to evaluate the insulation integrity of electrical systems. By applying an alternating current (AC) voltage to insulation materials, these testers help identify potential breakdowns, locate weak points, and ensure that electrical equipment operates safely and efficiently. This article explores the principle of operation, applications, and important considerations when using AC dielectric testers.

Principle of Operation

The fundamental principle behind AC dielectric testing revolves around the measurement of insulation resistance. When an AC voltage is applied to an insulating material, it generates an electric field that takes effect across the insulation barrier. The efficacy of this barrier to resist electrical flow is indicative of its condition. The tester primarily measures two important parameters insulation resistance and capacitive leakage current.

Insulation resistance is determined by the voltage that a dielectric material can withstand without allowing current to pass through. A higher insulation resistance indicates a better insulating property. On the other hand, the capacitive leakage current reflects the extent to which electrical energy seeps through the insulation under operational conditions. By analyzing these measurements, technicians can ascertain the overall health and functionality of electrical systems.

Applications

AC dielectric testers are widely employed across various industries, including power generation, manufacturing, telecommunications, and construction

. They are vital for1. Preventive Maintenance Regular testing of insulation materials ensures that equipment operates safely and reduces the likelihood of unexpected failures. 2. Quality Control Manufacturers utilize these testers to assess the quality of insulating materials during production, ensuring that they meet industry standards. 3. Safety Inspections Compliance with safety regulations mandates routine testing of electrical systems, especially in environments where equipment is exposed to harsh conditions. 4. Field Testing Technicians can perform on-site testing to diagnose problems with equipment before a failure occurs, saving time and resources.

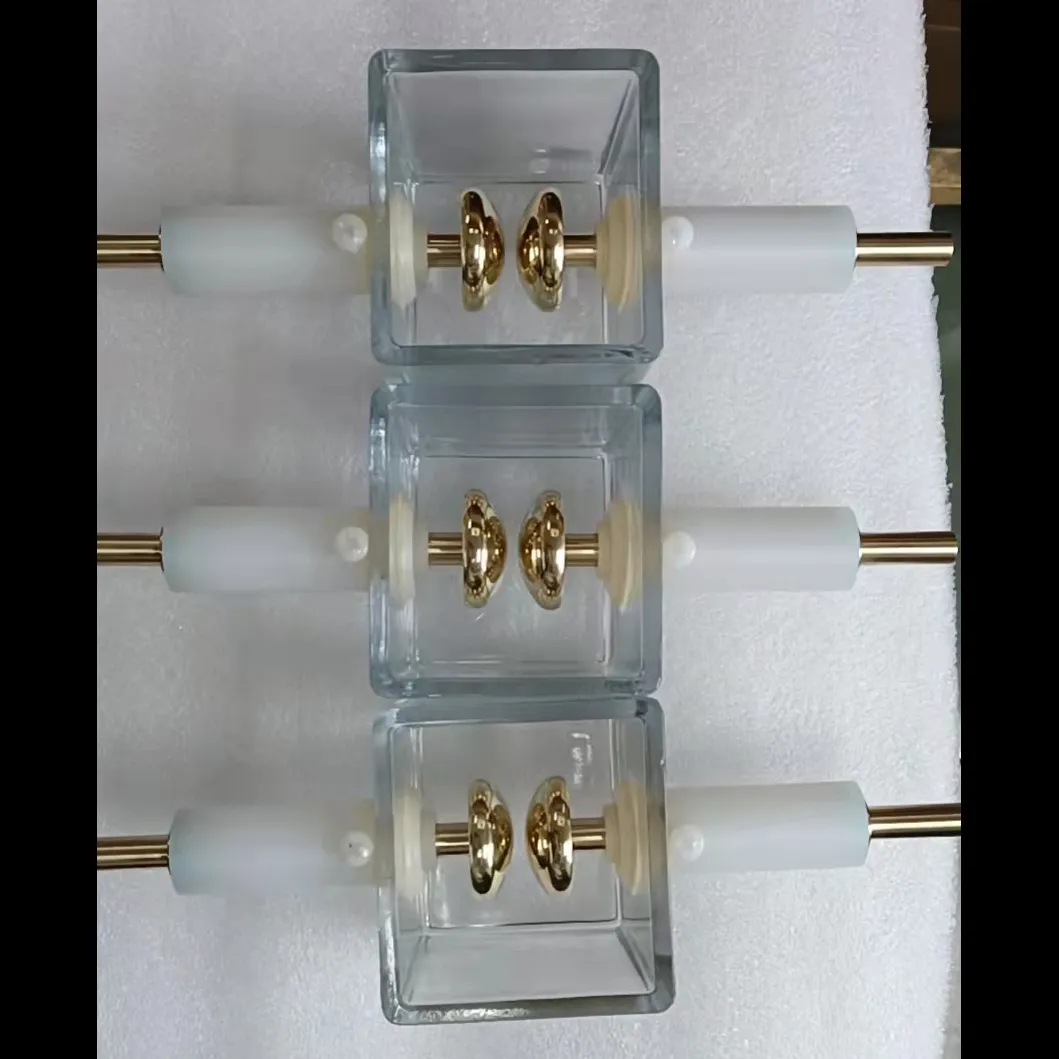

ac dielectric tester

Important Considerations

When using an AC dielectric tester, several considerations must be taken into account to ensure accurate results and operator safety

- Voltage Ratings It is essential to select a tester with appropriate voltage ratings for the specific application. Too high a voltage can damage sensitive equipment, while too low a voltage may not provide an accurate assessment of insulation integrity.

- Calibration and Maintenance Regular calibration of the tester is crucial to obtain reliable measurements. Additionally, proper maintenance of the device prolongs its lifespan and ensures consistent performance.

- Environmental Conditions Factors such as temperature and humidity can significantly affect test results. Tests should be conducted under controlled conditions whenever possible.

- Operator Training Adequate training on the operation of AC dielectric testers is imperative. Understanding how to interpret results and addressing any anomalies is vital for effective decision-making regarding equipment reliability.

Conclusion

In summary, AC dielectric testers are indispensable tools in the realm of electrical insulation evaluation. Their ability to provide reliable data regarding insulation integrity makes them essential for maintenance, quality control, and safety inspections across various industries. By considering key factors such as device specifications, environmental conditions, and operator training, users can maximize the effectiveness of AC dielectric testers and contribute to the safety and efficiency of electrical systems. As technology advances, these devices continue to evolve, offering enhanced features and improved accuracy, making them an essential part of any electrical maintenance toolkit.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024