English

English

Exploring the Significance of Tan Delta Testing in Material Characterization and Quality Assessment

Understanding Tan Delta Testing A Key Tool for Electrical Insulation Evaluation

Tan delta testing, also known as loss angle or dissipation factor testing, is a crucial diagnostic method employed to assess the condition of electrical insulating materials. This technique plays a significant role in maintenance and evaluation strategies across various industries, particularly in electrical engineering and power distribution systems. Understanding the principles, applications, and advantages of tan delta testing can provide critical insights into the integrity and reliability of insulation systems.

Principles of Tan Delta Testing

The tan delta (tan δ) value represents the ratio of the resistive current (lossy component) to the capacitive current (ideal component) in an insulating material. This relationship can be expressed mathematically as

\[ \text{tan } \delta = \frac{I_{\text{loss}}}{I_{\text{cap}}} \]

Where \(I_{\text{loss}}\) is the current component due to insulation losses (often attributable to moisture, impurities, or aging), and \(I_{\text{cap}}\) is the current flowing due to the capacitance of the insulation. A high tan delta value indicates a greater loss in the system, which can lead to excessive heat generation and ultimately failure of the insulation.

During a typical tan delta test, an AC voltage is applied across the insulation, and the resulting current is measured. By analyzing the phase difference between the voltage and current, technicians can calculate the tan delta, providing a quantitative measure of insulation quality.

Applications of Tan Delta Testing

Tan delta testing is widely utilized in various applications, such as

1. High Voltage Equipment This includes transformers, cables, and switchgear. Regular testing helps identify potential failures before they can lead to significant outages or accidents. 2. Renewable Energy Systems In solar power and wind energy installations, tan delta testing helps ensure that the insulating materials are functioning efficiently, protecting both the equipment and the investment.

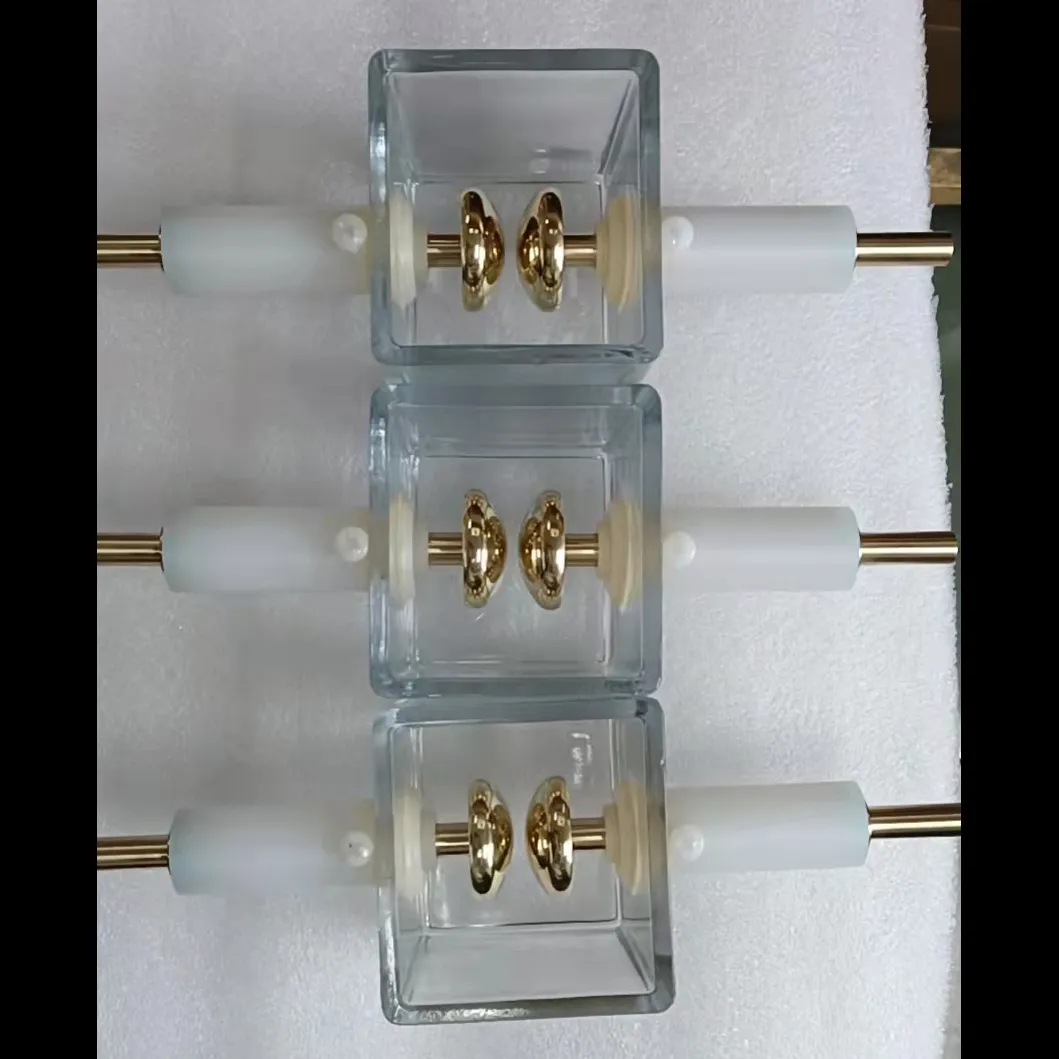

tan delta testing

3. Manufacturing and Quality Control In the production of electrical insulation materials, manufacturers use tan delta testing to confirm that their products meet industry standards and specifications.

4. Predictive Maintenance By scheduling regular tan delta tests, operators can develop a maintenance strategy based on the actual condition of their insulation systems, thereby optimizing operational reliability and lifecycle management.

Advantages of Tan Delta Testing

Tan delta testing offers several distinct advantages

- Early Detection of Problems By identifying insulation deterioration before it leads to catastrophic failures, operators can mitigate risks and costs associated with unplanned outages.

- Quantitative Data The test results provide objective data that can be used to track changes in insulation quality over time, thus enabling more effective maintenance planning and resource allocation.

- Non-Intrusive Tan delta testing is typically performed without needing to decommission equipment, allowing ongoing operations while maintaining safety and performance standards.

- Wide Applicability This method can be used on various materials, including cables, bushings, and various other insulation systems, making it a versatile tool in the electrical engineering field.

Conclusion

In conclusion, tan delta testing is an invaluable tool in the evaluation and maintenance of electrical insulation systems. By providing critical insights into the condition of insulating materials, it helps prevent costly failures and optimize operational efficiency in various applications. As technology advances and more sophisticated testing methods emerge, tan delta testing will continue to be an essential part of ensuring the reliability and longevity of electrical infrastructure globally. Understanding this testing technique empowers engineers and technicians to make informed decisions about the health and maintenance of their electrical systems.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024