English

English

furnace transformer test

Understanding Furnace Transformer Testing

Furnace transformer testing is an essential procedure in ensuring the reliability and efficiency of transformers used in industrial furnaces. These transformers are critical components in providing the necessary power to operate melting and heating systems, which are vital to various manufacturing processes, including steel production, metal casting, and glass manufacturing. Testing ensures that these transformers perform optimally and safely under the demanding conditions typical of furnace operations.

Transformers used in furnaces differ significantly from standard power transformers. They are typically designed to withstand harsh operating environments, including high temperatures and fluctuations in electrical load. Therefore, specialized testing methods are employed to evaluate their performance and longevity. This article discusses the significance, methods, and benefits of furnace transformer testing.

Importance of Testing

The importance of furnace transformer testing cannot be overstated. Transformers are subject to mechanical stress, thermal cycling, and electrical load variations. Any failure can lead to production downtimes, costly repairs, and even safety hazards. Regular testing helps in early detection of potential failures, ensuring that transformers operate within their designed parameters and preventing catastrophic failures that could halter production processes.

Moreover, testing is critical for compliance with industry standards and regulations. Many industries require strict adherence to safety and performance standards, and regular transformer testing helps organizations meet these requirements while maintaining high operational efficiency.

Testing Methods

There are several testing methods used to evaluate furnace transformers

furnace transformer test

1. Insulation Resistance Testing This involves measuring the insulation resistance of the transformer windings. Low insulation resistance could indicate deterioration of insulating materials, leading to potential shorts or failures.

2. Transformer Turns Ratio (TTR) Testing This test assesses the turns ratio between the primary and secondary windings of the transformer. An incorrect ratio can lead to imbalanced loads and inefficiencies.

3. Power Factor Testing This evaluates the power factor of the insulation system and helps identify issues related to capacitance and power losses within the transformer.

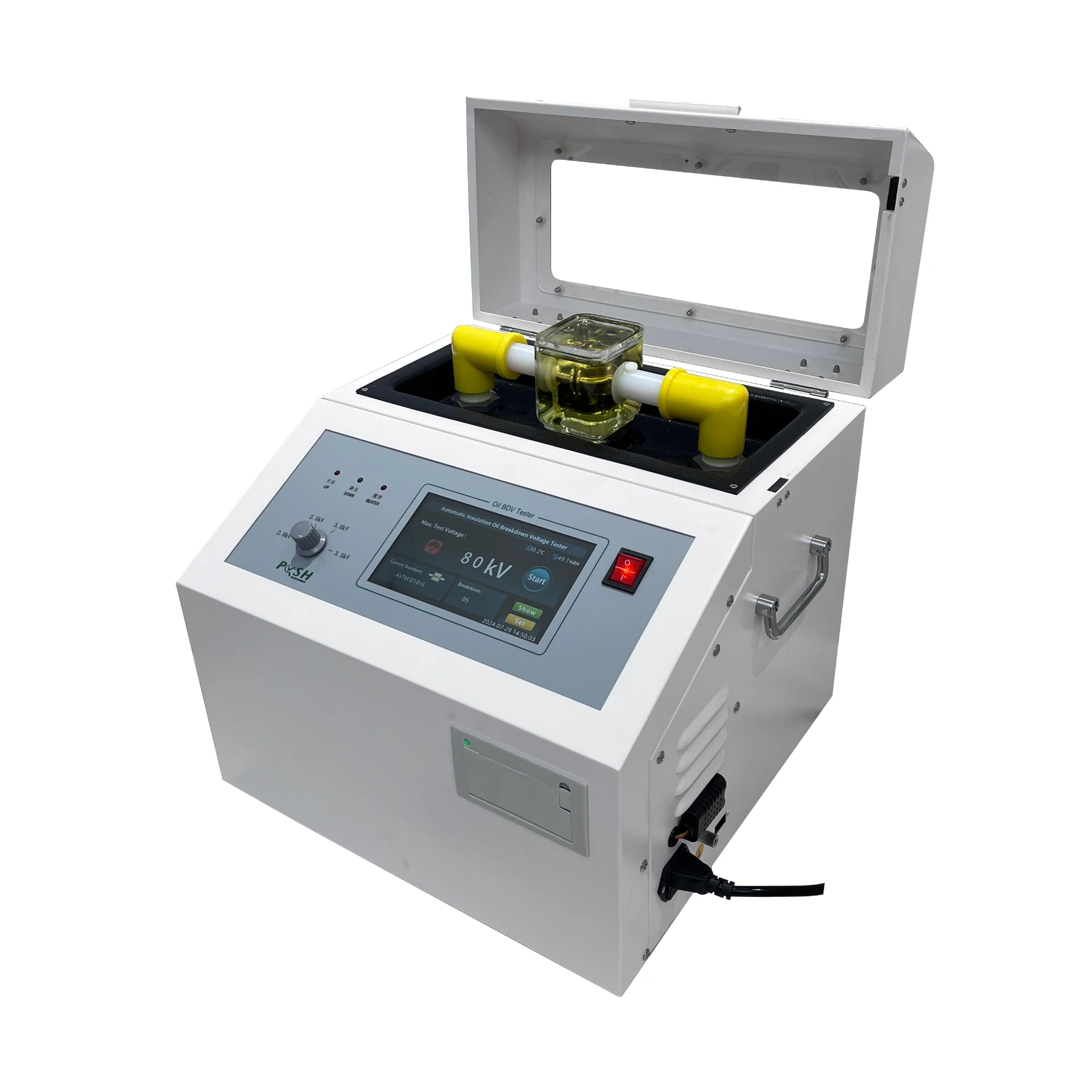

4. Dissolved Gas Analysis (DGA) This test involves analyzing the gases dissolved in the transformer oil. Different gas compositions can indicate various types of faults within the transformer, including overheating or electrical discharges.

5. Temperature Rise Testing This testing assesses the transformer's temperature under load conditions. High temperature rises can indicate issues such as inadequate cooling or excessive loads.

Benefits of Testing

The benefits of regular furnace transformer testing are manifold. Firstly, it enhances equipment performance and reliability, allowing for uninterrupted operations. Secondly, it extends the lifespan of transformers, leading to lower maintenance and replacement costs. Thirdly, it significantly improves safety by reducing the risk of transformer failures, which can cause accidents and injuries.

In conclusion, furnace transformer testing is a vital aspect of maintaining industrial efficiency and safety. By regularly assessing the condition and performance of these critical components, manufacturers can ensure high productivity, compliance with industry standards, and enhanced operational reliability. As industries continue to evolve, the significance of such testing will only grow, making it an indispensable practice in modern manufacturing processes.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024