English

English

Testing Methods for Furnace Transformers and Their Performance Evaluation Techniques

The Importance of Transformer Testing in Furnace Applications

In industrial settings, transformers play a crucial role in power distribution, particularly when connected to furnaces. They ensure that electrical energy is efficiently converted from one voltage level to another, making it suitable for various applications, especially those requiring high power for processes like melting and refining metals. However, the reliability and performance of transformers are critical, and this is where transformer testing comes into play.

Transformer testing is indispensable in ensuring that these systems operate safely and efficiently. When transformers are connected to furnaces, the stakes are significantly high. A malfunction can lead to substantial energy losses, equipment damage, and even safety hazards. Therefore, comprehensive testing protocols are essential to identify potential issues before they escalate.

Types of Transformer Tests

There are several types of transformer tests conducted to assess performance and safety, primarily categorized into routine, type, and special tests.

1. Routine Tests These are carried out on every transformer to verify basic functionality and performance metrics. They typically include tests for voltage ratios, winding resistance, insulation resistance, and turns ratio. These tests help ensure that the transformer adheres to the specified operational standards.

2. Type Tests Unlike routine tests, type tests are performed on a specific transformer design. This could involve tests such as temperature rise tests, short-circuit tests, and insulation tests. Type tests help in understanding how a transformer will perform under extreme conditions, which is particularly important in furnace operations where high currents and thermal loads are involved.

3. Special Tests These are tailored tests addressing specific operational conditions or issues. For instance, in environments where transformers are subjected to vibration or shock, special tests simulating these conditions would be beneficial.

Key Testing Procedures

furnace transformer test

Transformer testing encompasses various key procedures that help in diagnosing and ensuring safety.

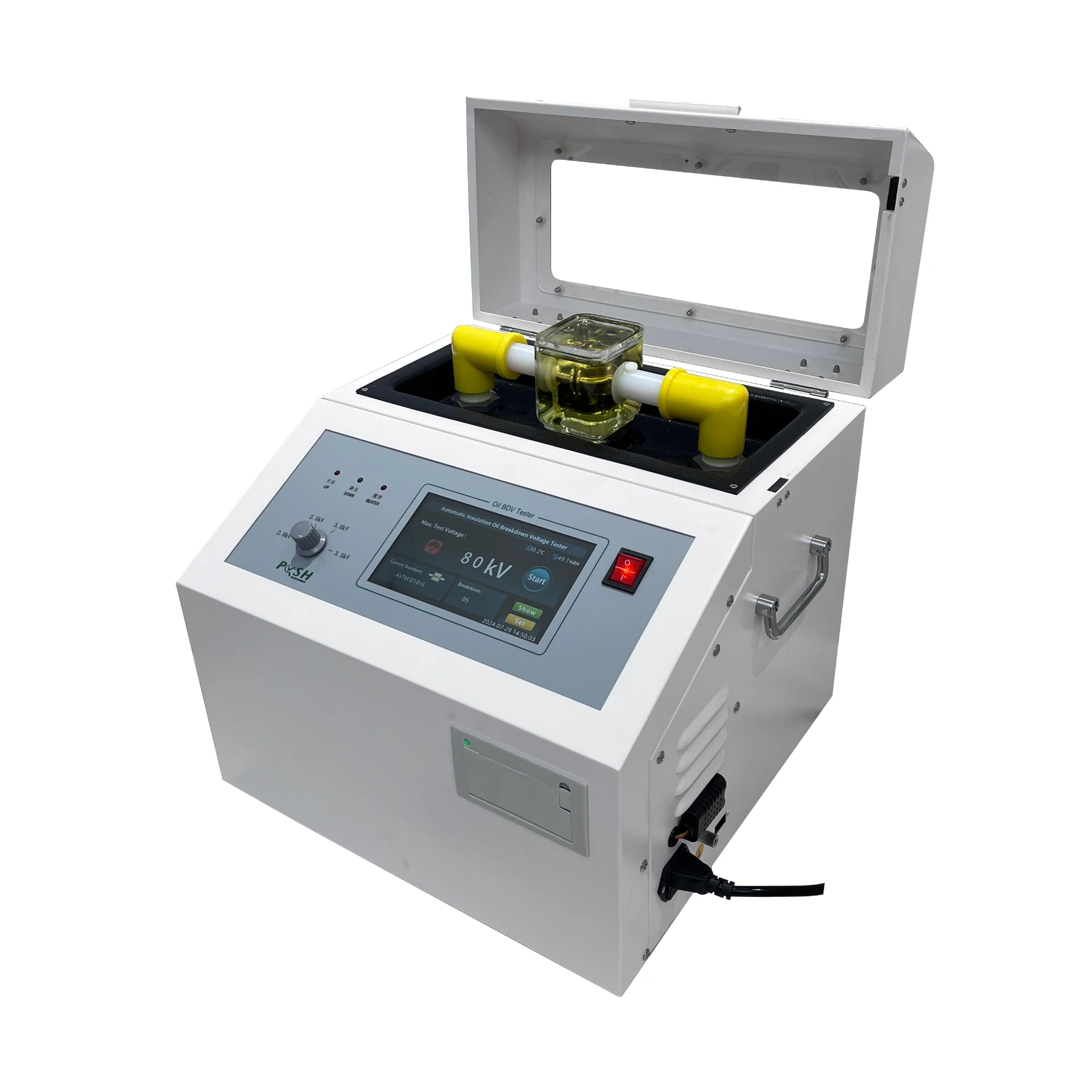

- Insulation Resistance Testing This test measures the resistance offered by the insulating materials within the transformer. High resistance values indicate good insulation, while low resistance can point toward degradation, potentially leading to short circuits.

- Transformer Turns Ratio (TTR) Testing Ensuring that the turns ratio between the primary and secondary windings is correct is vital for transformer performance. Any discrepancy can lead to voltage imbalances.

- Power Factor Testing This is crucial for assessing the dielectric loss of a transformer’s insulation. A high dielectric loss may indicate aging or deterioration of materials.

- Thermal Imaging Utilizing infrared thermography can detect hot spots that may signify potential failure points, enabling preemptive maintenance before a significant issue arises.

The Role of Continuous Monitoring

While thorough testing during installation is crucial, continuous monitoring can significantly enhance the long-term reliability of transformers. Modern techniques such as the implementation of condition monitoring systems can track various parameters in real-time, alerting operators to any anomalies before they escalate. These systems can measure temperature, partial discharge, and even load conditions, providing invaluable data points for maintenance.

Conclusion

The significance of transformer testing, especially in furnace applications, cannot be overstated. Implementing rigorous testing protocols and ensuring continuous monitoring not only enhances the operational efficiency of transformers but also safeguards against unforeseen failures. By investing in these practices, industries can ensure a reliable power supply, optimize energy consumption, and ultimately, improve overall safety in their operations. In an era where efficiency and sustainability are paramount, understanding and prioritizing transformer testing is a step towards achieving these crucial objectives.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024