English

English

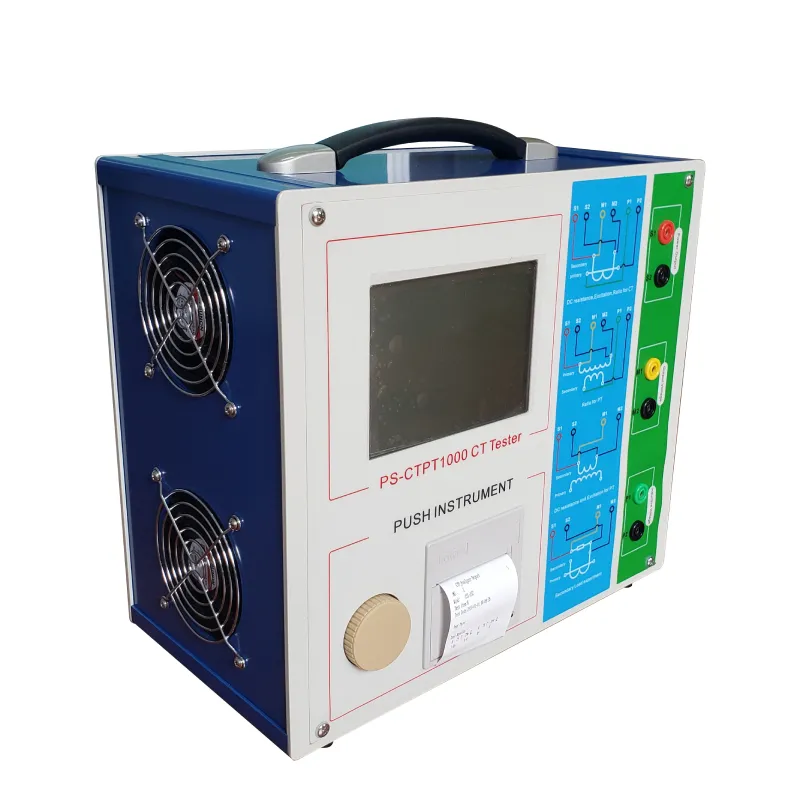

High Voltage Insulation Testing Equipment for Enhanced Dielectric Strength Evaluation

High Voltage Dielectric Tester An Essential Tool for Electrical Safety

In the realm of electrical engineering and maintenance, the safety and reliability of electrical systems are paramount. One indispensable instrument in ensuring these qualities is the high voltage dielectric tester. This sophisticated device plays a critical role in assessing the insulation strength of various electrical components, ensuring that they can operate safely at high voltages without failure.

Understanding Dielectric Testing

Dielectric testing involves applying a high voltage to an insulator while measuring its ability to withstand that voltage without breaking down. The primary goal is to detect any weaknesses in the insulation material that could lead to electrical leakage or complete failure. This testing is crucial for various electrical equipment, including transformers, cables, capacitors, and switchgear.

The Importance of High Voltage Testing

Electrical systems are often subjected to stress that can degrade insulation over time. Factors such as aging, environmental conditions, and mechanical wear can reduce the effectiveness of insulation, leading to potential hazards. High voltage dielectric testers assess whether the insulation can handle the operational voltage plus any potential surges. By simulating extreme conditions, engineers and maintenance personnel can identify components that may pose a risk and take preventive measures.

How Does a High Voltage Dielectric Tester Work?

A high voltage dielectric tester works by generating a controlled high voltage, typically ranging from 1 kV to over 100 kV, depending on the specific application and standards. The tester applies this voltage across the insulation material under test. It then monitors the current that flows through the insulation to identify any breakdown or leakage paths.

The most common tests performed using dielectric testers include

high voltage dielectric tester

1. Insulation Resistance Testing This method measures the resistance of the insulation to direct current (DC). A high resistance value indicates good insulation, while a low value suggests deterioration.

2. Dielectric Withstand Testing Also known as hi-pot testing, this method applies a high AC voltage for a short duration to ensure that the insulation can withstand surges without failing.

3. Leakage Current Testing This test measures the current that flows through the insulation when subjected to high voltage. Elevated leakage current can indicate insulation failure.

4. Polarization Index Testing By applying a DC voltage for 10 minutes and then a higher voltage for another 10 minutes, this test measures the insulation's ability to survive under stress.

Applications of High Voltage Dielectric Testers

These testers are widely utilized in various sectors, including

- Power Generation and Distribution Ensuring the reliability of transformers, conductors, and other equipment in power plants and substations. - Manufacturing Testing the dielectric properties of newly manufactured electrical equipment and components. - Maintenance Routine testing on existing equipment to detect insulation issues before they lead to failure. - Research and Development Evaluating new materials and designs for innovative electrical components in laboratories.

Conclusion

Incorporating high voltage dielectric testing into regular maintenance schedules is essential for ensuring the longevity and safety of electrical systems. By identifying insulation defects early, organizations can prevent costly downtime and accidents, safeguarding both personnel and equipment. As technology advances and electrical systems become more complex, the role of the high voltage dielectric tester will continue to be vital in maintaining high standards of safety and reliability in the electrical industry.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024