English

English

hipot test leakage current

Understanding Hipot Testing and Leakage Current

Hipot testing, short for high potential testing, is a crucial procedure in electrical safety assessments, particularly in the manufacturing of electrical and electronic devices. This test is designed to ensure that insulation within a device can withstand high voltage levels without breaking down. By doing so, it helps manufacturers prevent electrical shocks and potential hazards to users.

What is Hipot Testing?

Hipot testing involves applying a voltage significantly higher than the device's normal operating voltage. Typically, this test is performed at voltages ranging from 500 to 5000 volts, depending on the application and device specifications. The purpose is to determine the reliability and effectiveness of the insulation system. During the test, if the insulation fails, it can lead to excessive leakage current, which can be dangerous both for the device's functionality and user safety.

Leakage Current Explained

Leakage current is the small amount of electrical current that flows through the insulation of a device when subjected to electrical stress during a hipot test. Ideally, a well-insulated device should exhibit negligible leakage current. However, any measurable leakage current indicates a potential failure in insulation integrity. This can lead to electrical shocks or equipment damage if the device is connected to the power supply.

There are different types of leakage current capacitive, resistive, and inductive. Capacitive leakage current is often associated with capacitive coupling in circuits, while resistive leakage current arises from faulty insulation material or poor connections. Inductive leakage current typically involves magnetic fields around current-carrying conductors. Understanding these components is essential for effective testing and safety.

The Importance of Hipot Testing and Leakage Current Measurement

hipot test leakage current

Maintaining safety standards in electronic devices is non-negotiable, especially in industries like healthcare, automotive, and consumer electronics. Hipot testing plays a significant role in this context

1. Safety Assurance By identifying insulation flaws before products reach consumers, hipot testing mitigates the risk of electrical shock and ensures compliance with safety regulations.

2. Quality Control Manufacturers can implement hipot testing as part of their quality control process to maintain high production standards. By assessing each device's insulation integrity, companies can reduce warranty claims and enhance their reputation in the market.

3. Regulatory Compliance Various regulatory bodies, such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC), outline mandatory safety standards that include hipot testing. Compliance with these regulations not only protects end-users but also shields manufacturers from legal liabilities.

4. Device Longevity Effective insulation ensures that devices operate efficiently over time, reducing the risk of breakdowns or failures that can lead to costly repairs or replacements. Regular hipot testing can help identify potential issues before they become significant problems.

Conclusion

In conclusion, hipot testing and leakage current measurement are vital components of electrical safety in device manufacturing. By understanding the principles of hipot testing and the implications of leakage current, manufacturers can enhance product safety, comply with industry regulations, and guarantee customer satisfaction. As technology continues to evolve and devices become ever more complex, the importance of rigorous safety testing, including hipot tests, cannot be overstated. Investing in proper testing procedures and equipment is ultimately an investment in consumer trust and product reliability.

-

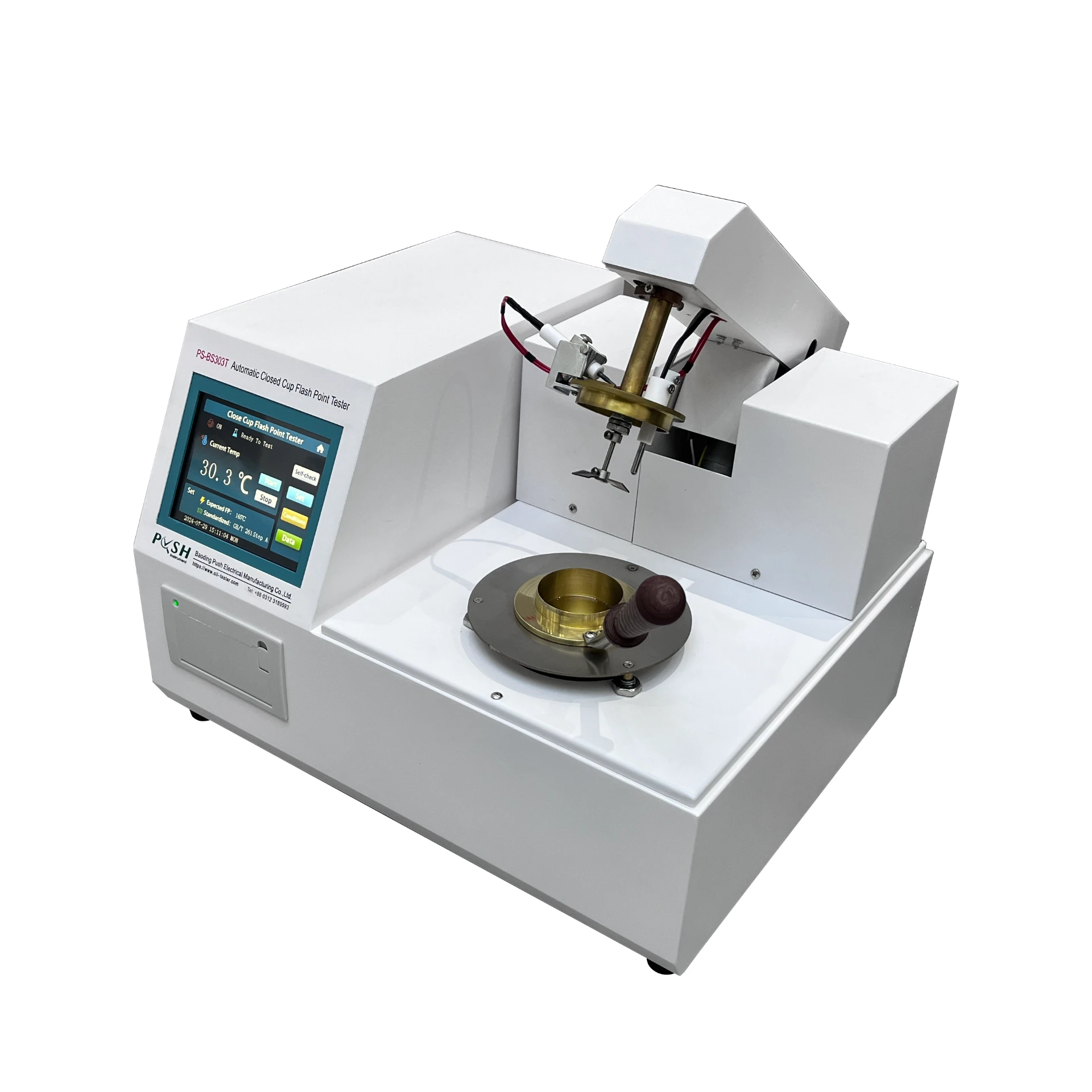

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024