English

English

Impulse Testing Methodologies for Transformer Performance Evaluation and Optimization Techniques

Impulse Testing of Transformers An Essential Procedure for Ensuring Reliability

Impulses, particularly in electrical engineering, refer to sudden spikes in voltage or current that can occur due to various factors, including lightning strikes or switching operations within a power system. Transformers, critical components in electrical transmission networks, must be robust enough to withstand such events without failure. Impulse testing serves as a vital diagnostic tool for assessing the insulation strength and overall reliability of transformers, ensuring their safe and efficient operation.

Understanding Impulse Testing

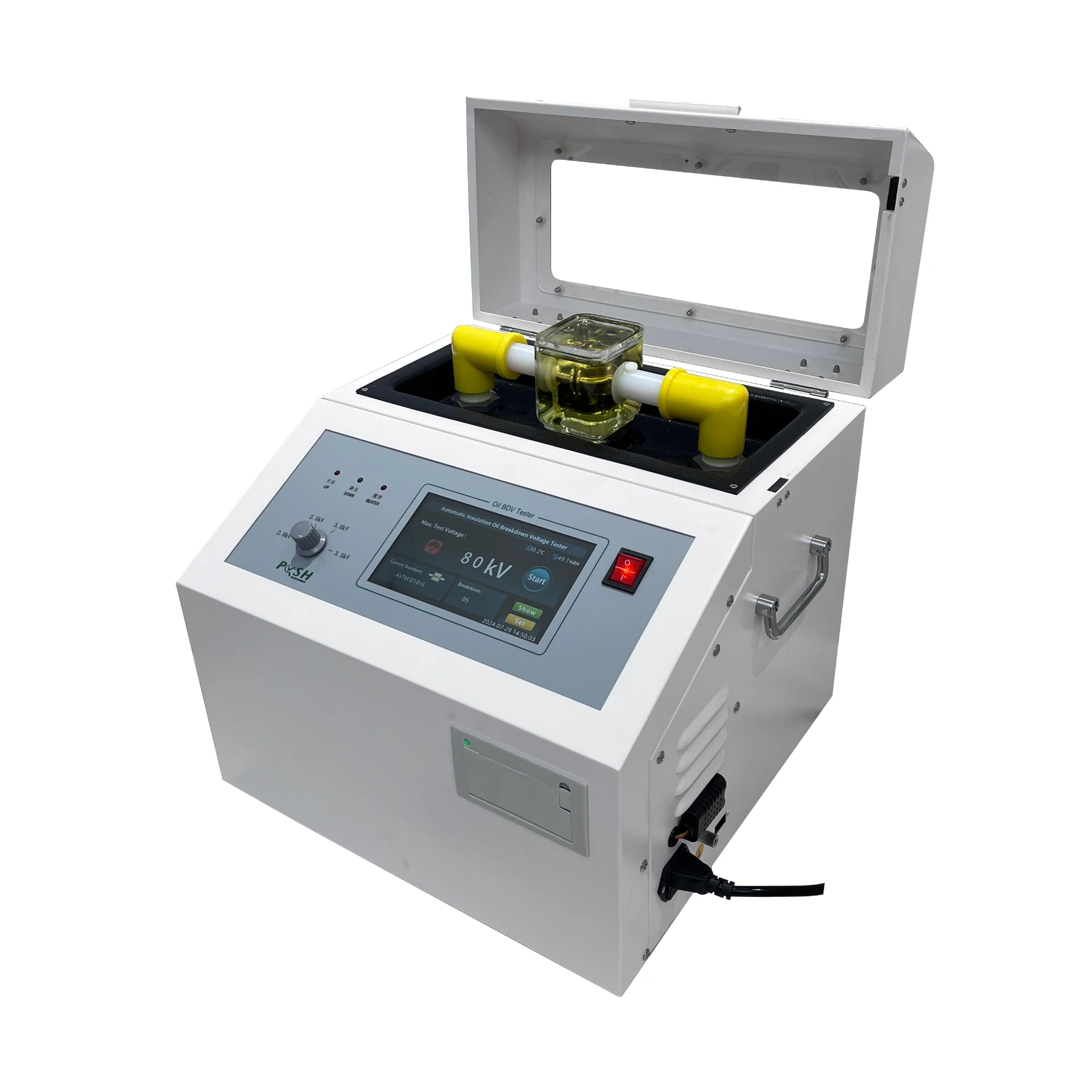

Impulse testing is fundamentally designed to simulate the electrical and mechanical stresses that transformers may experience during their operational lifetime. The procedure typically involves subjecting the transformer to high-voltage impulses that replicate the voltage surges that can occur in real-life scenarios. These voltage impulses are characterized by their steep wavefronts and rapid decay, typically generated using a specialized apparatus known as an impulse generator.

Significance of Impulse Testing

1. Insulation Verification The primary objective of impulse testing is to evaluate the integrity of the insulation systems within transformers. Insulation materials can degrade over time due to environmental factors, electrical stress, or physical wear. By applying high-voltage impulses, engineers can identify weaknesses or failures in the insulation that might not be detectable under normal operating conditions.

2. Failure Prediction Regular impulse testing can help predict potential insulation failures before they lead to catastrophic breakdowns. By understanding the performance of insulation under stress, utility companies and maintenance personnel can schedule necessary maintenance or upgrades, ultimately reducing outage times and repair costs.

3. Compliance and Standards Many national and international standards (such as IEC 60076) require impulse testing as part of the certification process for transformers. By adhering to these standards, manufacturers can ensure that their products are capable of withstanding transient overvoltages, providing assurance to end-users of their reliability and safety.

Procedures Involved in Impulse Testing

impulse testing of transformer

The impulse testing process generally follows a structured protocol

1. Preparation Prior to the test, the transformer is inspected, and all necessary safety precautions are established. This includes grounding procedures and ensuring that all personnel are at a safe distance during the testing.

2. Connection to the Impulse Generator The transformer is connected to the impulse generator through appropriate testing leads. The setup includes various measuring devices to monitor voltage, current, and time responses during testing.

3. Generation of Impulse Once the setup is complete, the impulse generator tests the transformer by delivering a series of voltage impulses. These impulses are typically of a few microseconds in duration with steep rise times, emulating the electrical conditions transformers might face externally.

4. Data Analysis After the testing is complete, engineers analyze the data collected during the test, looking for signs of insulation failure or weaknesses. Techniques such as partial discharge measurement can be employed to provide further insights into the insulation quality.

Interpretation of Results

The results from impulse testing provide critical information about the condition of the transformer's insulation system. A successful test generally indicates that the insulation is capable of handling the expected electrical stresses. Conversely, any breakdown during testing suggests a need for further investigation, repairs, or even replacement of the transformer.

Conclusion

Impulse testing of transformers is an essential part of their life cycle assessment, contributing significantly to the overall reliability and safety of electrical power systems. By simulating real-world electrical stresses, this testing method enables utilities and manufacturers to ensure that their transformers can perform effectively under potential surge conditions. As global energy demands continue to rise, investing in such diagnostics not only enhances infrastructure resilience but also promotes sustainable energy practices by minimizing the risks associated with transformer failures.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024