English

English

Innovative Approaches to Transformer Infrared Inspection for Enhanced Maintenance and Reliability

Transformative Advances in Infrared Inspection Technology

In recent years, the application of infrared (IR) inspection technology has seen transformative advancements, especially with the integration of transformer systems. As industries seek more efficient and reliable methods for monitoring and maintaining their equipment, infrared inspection has emerged as a critical tool in preventive maintenance and quality assurance processes. This article delves into the significance of infrared inspection in transformer technology, highlighting its benefits, applications, and future prospects.

Transformative Advances in Infrared Inspection Technology

One of the primary benefits of infrared inspection is its ability to enhance safety and reliability. In the context of transformers, overheating can lead to catastrophic failures, resulting in outages or even fires. By employing infrared scanning as part of routine maintenance schedules, engineers can detect hotspots before they evolve into serious problems. This proactive approach not only minimizes the risk to personnel and assets but also reduces downtime, ultimately improving operational efficiency.

transformer infrared inspection

Moreover, infrared inspection contributes to cost savings over time. Traditional methods of inspecting transformers often involve manual checks and guesswork, leading to potential oversights and costly repairs. In contrast, infrared technology provides precise and immediate insights into the condition of transformers. By catching faults early, operators can schedule maintenance at optimal times, avoiding more extensive repairs and associated costs. This predictive maintenance strategy allows companies to allocate their resources more effectively and extend the lifespan of their equipment.

The versatility of infrared inspection extends beyond the electrical sector. In industries such as renewable energy, transportation, and manufacturing, the principles of thermal imaging apply similarly. For example, in solar energy systems, infrared cameras can identify malfunctioning photovoltaic panels, ensuring optimal energy production. In transportation, thermal imaging can monitor vehicle components for heat discrepancies that indicate wear or malfunction. Thus, the cross-industry applicability of infrared inspection amplifies its significance and utility.

As we look toward the future, the ongoing integration of advanced technologies will further enhance the capabilities of infrared inspection systems. The incorporation of artificial intelligence (AI) and machine learning will enable infrared cameras to not only capture thermal images but also analyze data in real time. These intelligent systems could predict potential failures by learning from historical data and identifying patterns that human inspectors might overlook. Such advancements would revolutionize maintenance schedules, driving efficiency and innovation across various sectors.

In conclusion, infrared inspection technology, particularly in its application to transformers, represents a critical evolution in maintenance practices across multiple industries. Its ability to detect potential failures early, enhance operational safety, and save costs underscores its importance in modern equipment management. As technological advancements continue to progress, the role of infrared inspection is poised to expand, offering even greater capabilities in predictive maintenance and operational efficiency. In embracing these transforms, industries will ensure their equipment's reliability and safety, ultimately driving progress in their respective fields.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

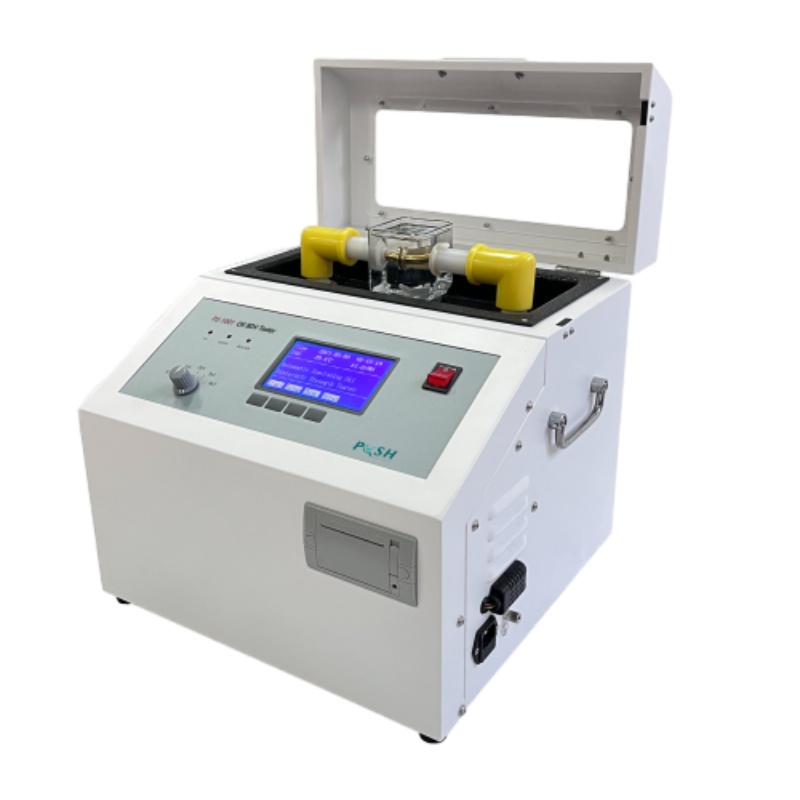

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024