TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 11, 2025 10:56

Back to list

insulation power factor test transformer

Transformers play an essential role in the transmission and distribution of electrical power. Ensuring their optimal performance is critical for the reliability and efficiency of power systems. One of the most informative diagnostic tests conducted on transformers is the insulation power factor test. Despite its importance, many professionals in the field seek a deeper understanding of this test's intricacies and its crucial role in transformer maintenance.

Another critical aspect of the insulation power factor test is its role in preventative maintenance strategies. Modern power systems increasingly lean on predictive and preventive maintenance over reactive maintenance. This shift is due to the understanding that proactive measures significantly reduce downtime and repair costs. By integrating routine insulation power factor testing into maintenance schedules, operators can detect subtle changes in insulation performance, much like a doctor uses blood tests to monitor a patient's health. Experts in the field emphasize the importance of creating a base data set from initial tests conducted when a transformer is newly commissioned and in peak condition. This baseline becomes a reference point against which future test results can be compared. Deviations from this baseline indicate changes in the insulation's condition, allowing maintenance teams to act swiftly. Moreover, the value of the insulation power factor test lies in its objectivity and reliability. Unlike visual inspections that can overlook hidden defects, the test's quantitative nature provides clear, objective data. This objectivity ensures that decisions regarding maintenance can be made based on tangible evidence rather than conjecture. Trustworthiness of the test results is further enhanced by the industry's adherence to international standards, which govern testing methodologies. Industry standards, such as those from the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC), provide detailed guidelines that testing professionals follow to ensure consistency and accuracy, further bolstering the test’s authority and acceptance worldwide. In summary, the insulation power factor test for transformers is an indispensable tool that combines expertise and precise data to enhance the reliability and efficiency of electrical power systems. By regularly employing this test as part of a comprehensive maintenance strategy, industry professionals can forestall failures, optimize transformer performance, and ensure continuity of power supply. As the dynamics of power systems evolve, the importance of such meticulous diagnostic testing only grows, cementing the insulation power factor test's role in modern electrical maintenance practices.

Another critical aspect of the insulation power factor test is its role in preventative maintenance strategies. Modern power systems increasingly lean on predictive and preventive maintenance over reactive maintenance. This shift is due to the understanding that proactive measures significantly reduce downtime and repair costs. By integrating routine insulation power factor testing into maintenance schedules, operators can detect subtle changes in insulation performance, much like a doctor uses blood tests to monitor a patient's health. Experts in the field emphasize the importance of creating a base data set from initial tests conducted when a transformer is newly commissioned and in peak condition. This baseline becomes a reference point against which future test results can be compared. Deviations from this baseline indicate changes in the insulation's condition, allowing maintenance teams to act swiftly. Moreover, the value of the insulation power factor test lies in its objectivity and reliability. Unlike visual inspections that can overlook hidden defects, the test's quantitative nature provides clear, objective data. This objectivity ensures that decisions regarding maintenance can be made based on tangible evidence rather than conjecture. Trustworthiness of the test results is further enhanced by the industry's adherence to international standards, which govern testing methodologies. Industry standards, such as those from the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC), provide detailed guidelines that testing professionals follow to ensure consistency and accuracy, further bolstering the test’s authority and acceptance worldwide. In summary, the insulation power factor test for transformers is an indispensable tool that combines expertise and precise data to enhance the reliability and efficiency of electrical power systems. By regularly employing this test as part of a comprehensive maintenance strategy, industry professionals can forestall failures, optimize transformer performance, and ensure continuity of power supply. As the dynamics of power systems evolve, the importance of such meticulous diagnostic testing only grows, cementing the insulation power factor test's role in modern electrical maintenance practices.

Previous:

Latest news

-

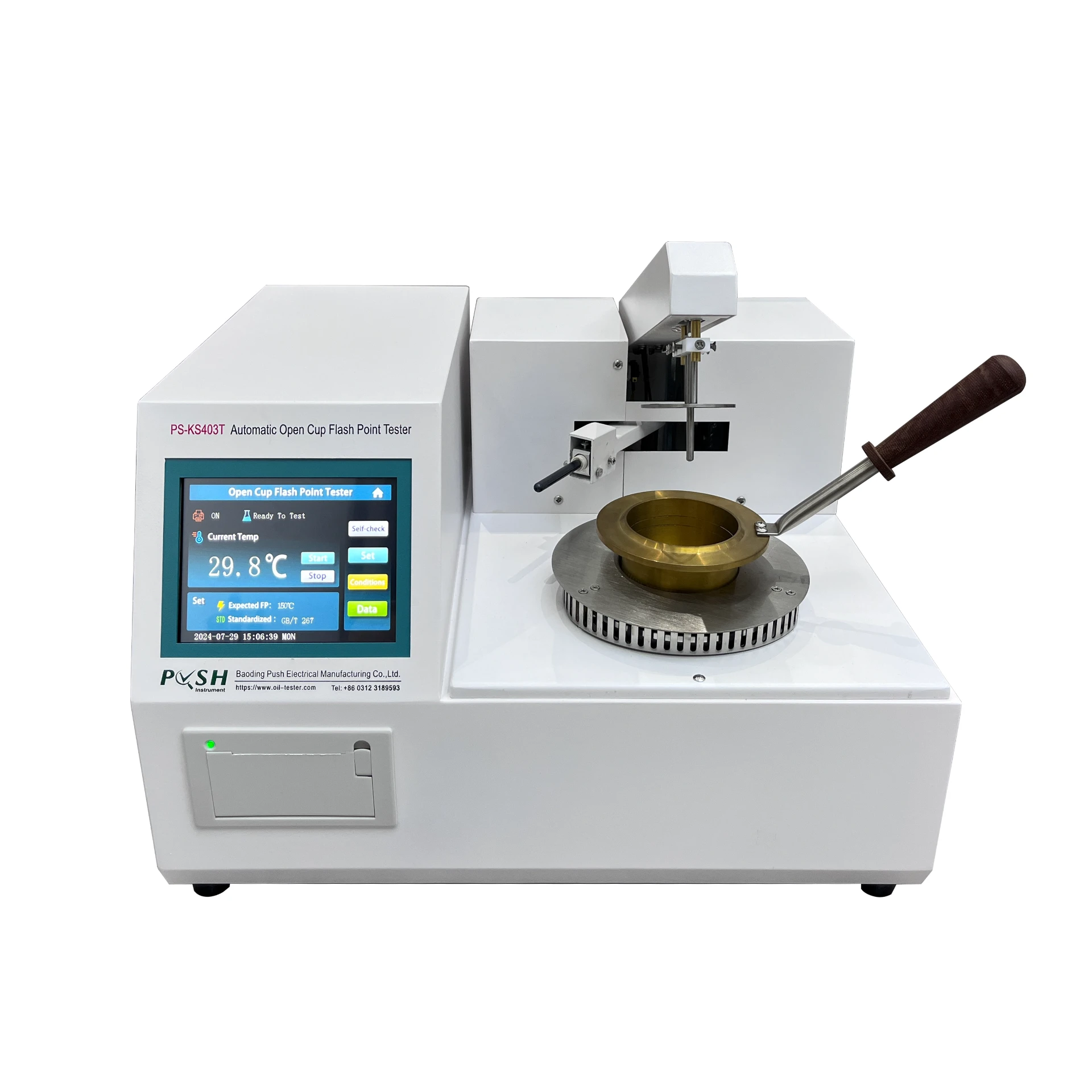

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024