English

English

Investigation of Zero Sequence Phenomena in Transformer Systems for Improved Performance Analysis

Zero Sequence Test of Transformers Importance and Methodology

Transformers are critical components in electrical power systems, enabling the efficient transfer of electrical energy between circuits while adjusting voltage levels. Ensuring their operational integrity is paramount, particularly in preventing faults that can lead to significant outages or equipment damage. One effective diagnostic technique employed in transformer maintenance is the zero sequence test, which plays a crucial role in assessing the condition of insulation and detecting internal faults.

What is the Zero Sequence Test?

The zero sequence test involves the application of zero sequence current or voltage to the transformer under test. This type of testing is particularly effective in identifying issues related to ground faults and short-circuit conditions. In a three-phase transformer, zero sequence currents arise when there is an imbalance in the phase currents or when a fault occurs that allows current to flow through the ground. By introducing zero sequence signals into the transformer, we can evaluate how these signals interact with its components, consequently revealing any weaknesses or abnormalities.

Importance of the Zero Sequence Test

1. Fault Detection The primary purpose of the zero sequence test is the detection of ground faults. These faults can be catastrophic if left unresolved, as they may lead to transformer failure or fires. The ability to identify such faults early can significantly enhance the safety and reliability of the electrical system.

2. Insulation Assessment Insulation is critical for the safe operation of transformers. The zero sequence test helps in evaluating the dielectric strength of the transformer insulation. Any degradation or compromise in the insulation can be detected through this test, allowing for timely maintenance actions that can prolong the transformer’s life.

3. Performance Monitoring Over time, transformers may develop various operational issues. Regularly conducting zero sequence tests can serve as a monitoring tool, providing insights into the changing health of the transformer and potentially indicating when more detailed inspections or repairs might be necessary.

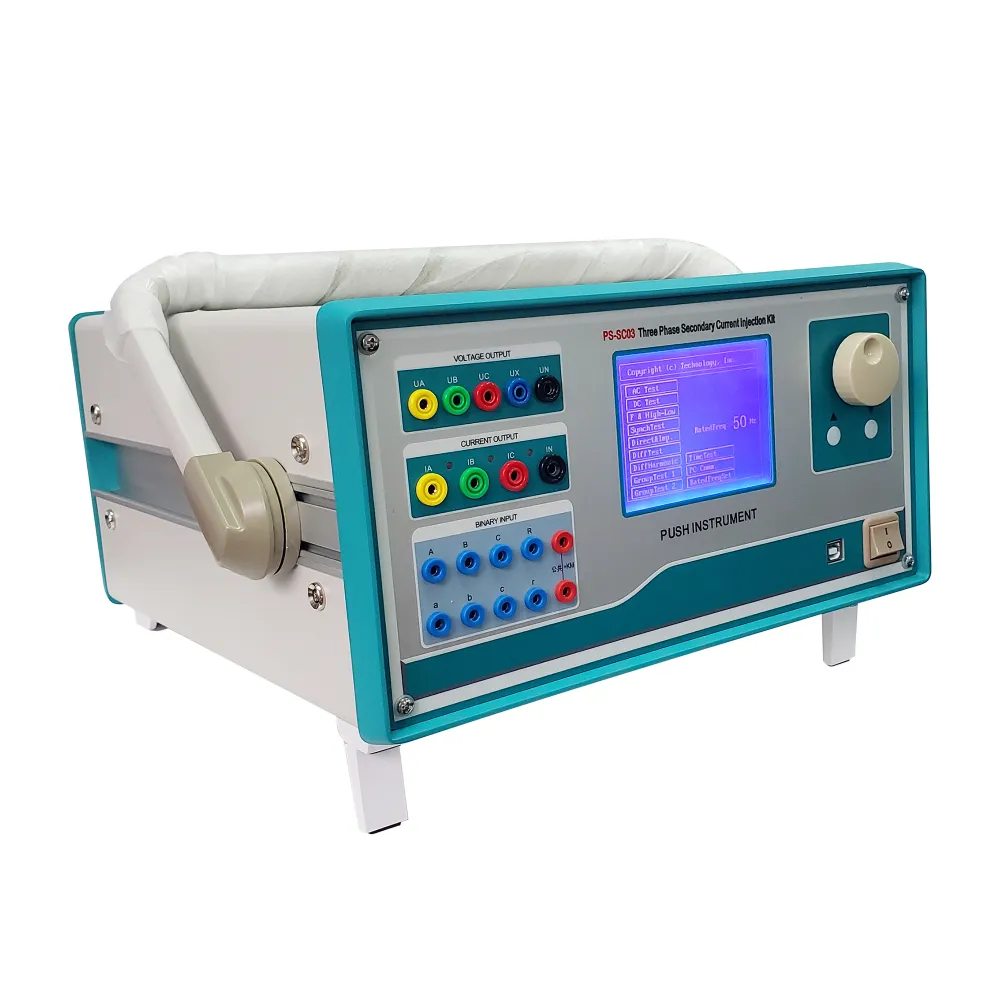

zero sequence test of transformer

Methodology

The zero sequence test is typically conducted by following a systematic process. Initially, safety precautions are observed to ensure that all personnel are protected during testing. The transformer is isolated from the power source, and necessary equipment is set up to apply the zero sequence voltage or current.

1. Connection Configuration The testing apparatus is connected to the primary and secondary sides of the transformer, ensuring that the proper configuration allows for the application of zero sequence current. This involves short-circuiting the phase windings in a specific manner to create a zero sequence condition.

2. Data Collection During the test, data is collected on the response of the transformer. This typically includes measurements of current, voltage, and any changes in temperature. The response of the transformer will provide insight into its condition and indicate whether any abnormalities exist.

3. Analysis Following the completion of the test, the gathered data is analyzed. Engineers will compare the results against baseline readings or manufacturers' specifications to determine the condition of the transformer. Any deviations from expected performance may suggest the presence of faults or insulation weaknesses.

Conclusion

The zero sequence test is a valuable tool in the maintenance and diagnostics of transformers. By facilitating early detection of faults and monitoring insulation integrity, this test not only enhances the safety and reliability of electrical systems but also contributes to the longevity of transformers. Regular implementation of zero sequence testing should be an integral part of any transformer maintenance program, ensuring that operators can address potential issues before they lead to costly failures.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024