English

English

list of transformer testing

Understanding Transformer Testing A Comprehensive Overview

Transformers are crucial components in electrical power systems, serving the primary purpose of transferring electrical energy between circuits through electromagnetic induction. Given their importance, the testing of transformers is essential to ensure their efficiency, reliability, and safety. This article provides an overview of various transformer testing methods, highlighting their significance in maintaining optimal performance.

1. Insulation Resistance Testing

One of the most critical tests for transformers is the insulation resistance test. This test evaluates the quality of insulation materials within the transformer components, particularly between windings and to the ground. High insulation resistance indicates a healthy transformer, while low readings may point to moisture ingress or deterioration of insulation. Typically performed using a megohmmeter, this test ensures that the transformer can operate safely without risk of electrical leakage.

2. Transformer Turns Ratio (TTR) Testing

The transformer turns ratio test assesses the ratio of the primary to secondary winding turns. This parameter is crucial for the transformer's voltage regulation capabilities. The TTR test ensures that the turns ratio conforms to design specifications, which is vital for efficient energy transfer and performance. Any discrepancies could indicate internal winding issues or faults that need to be addressed before the transformer is put into service.

Power factor testing provides insights into the dielectric properties of the transformer's insulation system. By applying a voltage and measuring the current response, technicians can calculate the power factor, which indicates the quality of the insulation. A low power factor might suggest deterioration or contamination of the insulating materials, necessitating further inspection or maintenance.

list of transformer testing

4. Sweep Frequency Response Analysis (SFRA)

SFRA is an advanced diagnostic test used to evaluate the mechanical integrity of transformer windings. This method involves exciting the transformer with a range of frequencies and measuring the response. By comparing the frequency response of a transformer over time, technicians can identify potential issues such as winding displacement or deformation, which could lead to catastrophic failures if left unchecked.

5. Circuit Tests

Various circuit tests are performed to evaluate the operational condition of transformer components. These include testing for short circuits, open circuits, and measuring resistance in different electrical paths. Circuit tests also assess the performance of protective devices, ensuring that they function correctly under fault conditions.

6. Temperature Rise Test

Temperature rise testing simulates the transformer’s operational conditions to verify its thermal performance. By measuring the temperature increase during normal operation, technicians ensure that the transformer can handle its rated load without overheating. This test is essential for verifying cooling system efficiency and overall reliability.

Conclusion

Transformer testing is a vital aspect of maintaining power system reliability and performance. By conducting a series of rigorous tests, engineers can identify potential issues before they escalate into significant failures, ensuring that transformers operate safely and efficiently. Regular testing not only helps in extending the service life of transformers but also safeguards the integrity of the entire electrical system, contributing to a stable and reliable power supply.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

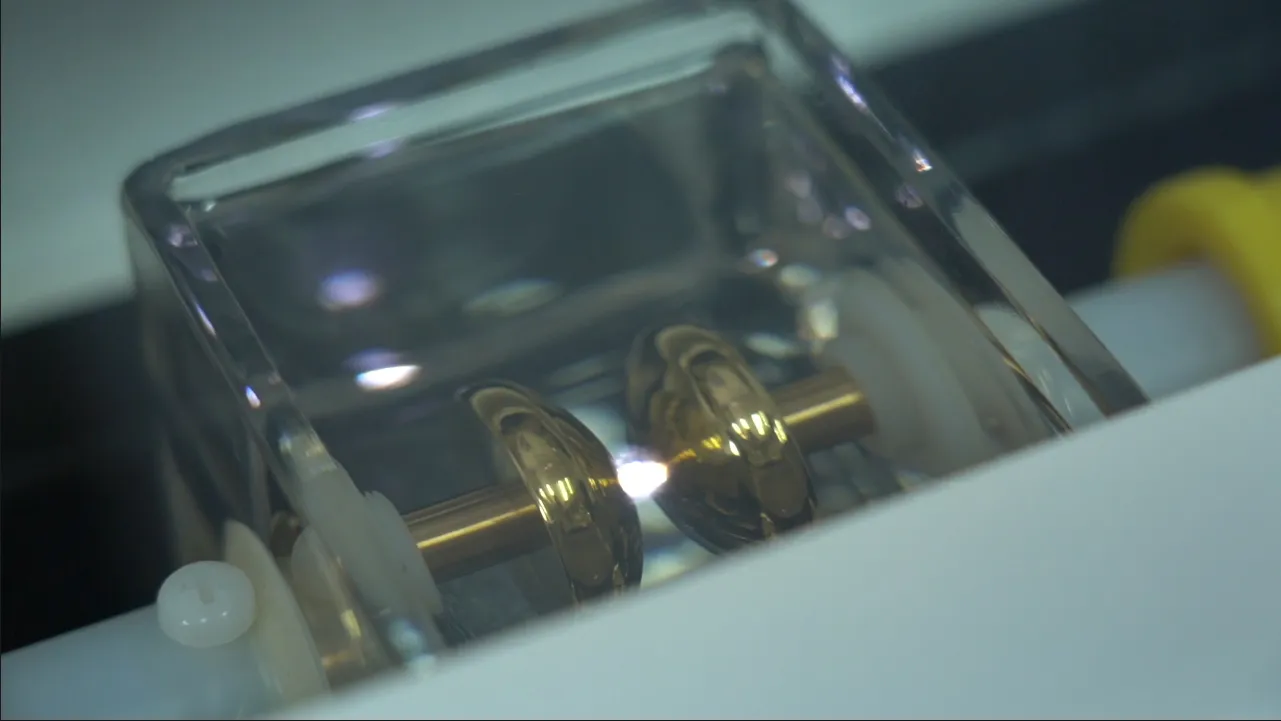

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024