TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

2 月 . 12, 2025 16:54

Back to list

PS-3045 High Voltage Insulation Resistance Tester

Conducting a load test on a three-phase transformer is a critical process for electrical engineers and technicians aiming to ensure the efficiency and reliability of power systems. Understanding this procedure not only demands technical expertise but also an appreciation for the intricate mechanisms powering our modern infrastructures. At its core, this activity is a testament to engineering ingenuity, shaping the backbone of electrical distribution networks worldwide.

Moreover, witnessing a transformer's performance during peak load conditions offers insights that spreadsheets and theoretical models cannot replicate. Visualizing how transformers manage surges and maintain voltage steadiness under load pressures is a powerful educational tool for budding engineers. From an experiential standpoint, the laboratory load test is not just a procedural necessity but a formative experience, enhancing problem-solving skills and fostering a deeper understanding of electrical systems. For industry experts, being involved in this meticulous process affirms their authoritative status, as their insights and expertise drive technological advancements and safety improvements. Manufacturers and power companies rely heavily on the integrity of these tests. Not only do they affirm the product's compliance with specifications, but they build trust with consumers and stakeholders. In an era where reliability and efficiency are paramount, a well-conducted load test serves as a reliable measure of quality assurance. In conclusion, the load test on a three-phase transformer is a testament to the meticulous and sophisticated nature of electrical engineering. It marries theoretical knowledge with practical application, strengthening the dependability of transformers globally. This robust process underscores the intersection of experience, expertise, authority, and trustworthiness, ensuring that the power systems running our economies remain steadfast and efficient. For individuals and organizations dedicated to excellence in power system management, excelling in this area is not optional but essential.

Moreover, witnessing a transformer's performance during peak load conditions offers insights that spreadsheets and theoretical models cannot replicate. Visualizing how transformers manage surges and maintain voltage steadiness under load pressures is a powerful educational tool for budding engineers. From an experiential standpoint, the laboratory load test is not just a procedural necessity but a formative experience, enhancing problem-solving skills and fostering a deeper understanding of electrical systems. For industry experts, being involved in this meticulous process affirms their authoritative status, as their insights and expertise drive technological advancements and safety improvements. Manufacturers and power companies rely heavily on the integrity of these tests. Not only do they affirm the product's compliance with specifications, but they build trust with consumers and stakeholders. In an era where reliability and efficiency are paramount, a well-conducted load test serves as a reliable measure of quality assurance. In conclusion, the load test on a three-phase transformer is a testament to the meticulous and sophisticated nature of electrical engineering. It marries theoretical knowledge with practical application, strengthening the dependability of transformers globally. This robust process underscores the intersection of experience, expertise, authority, and trustworthiness, ensuring that the power systems running our economies remain steadfast and efficient. For individuals and organizations dedicated to excellence in power system management, excelling in this area is not optional but essential.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

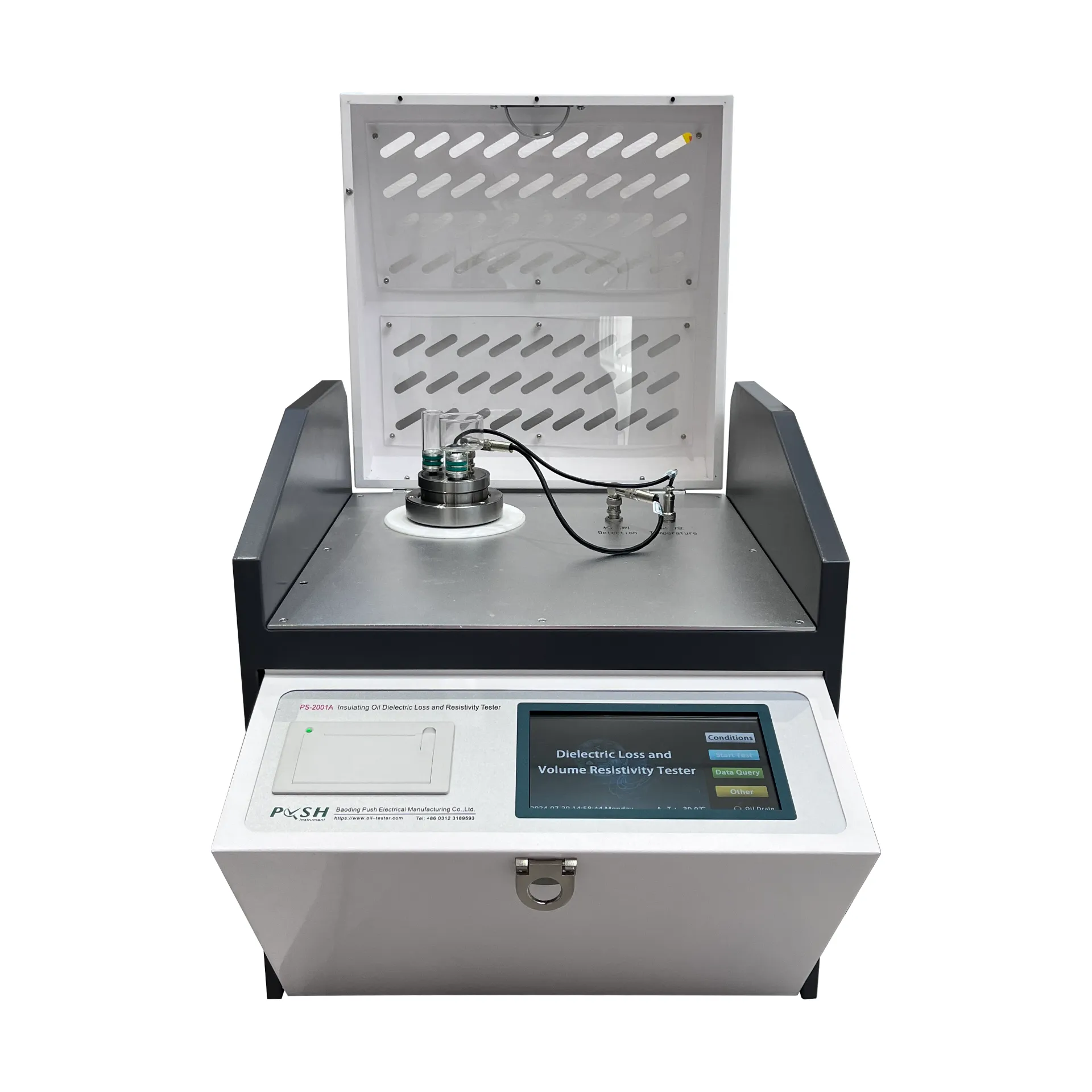

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024