English

English

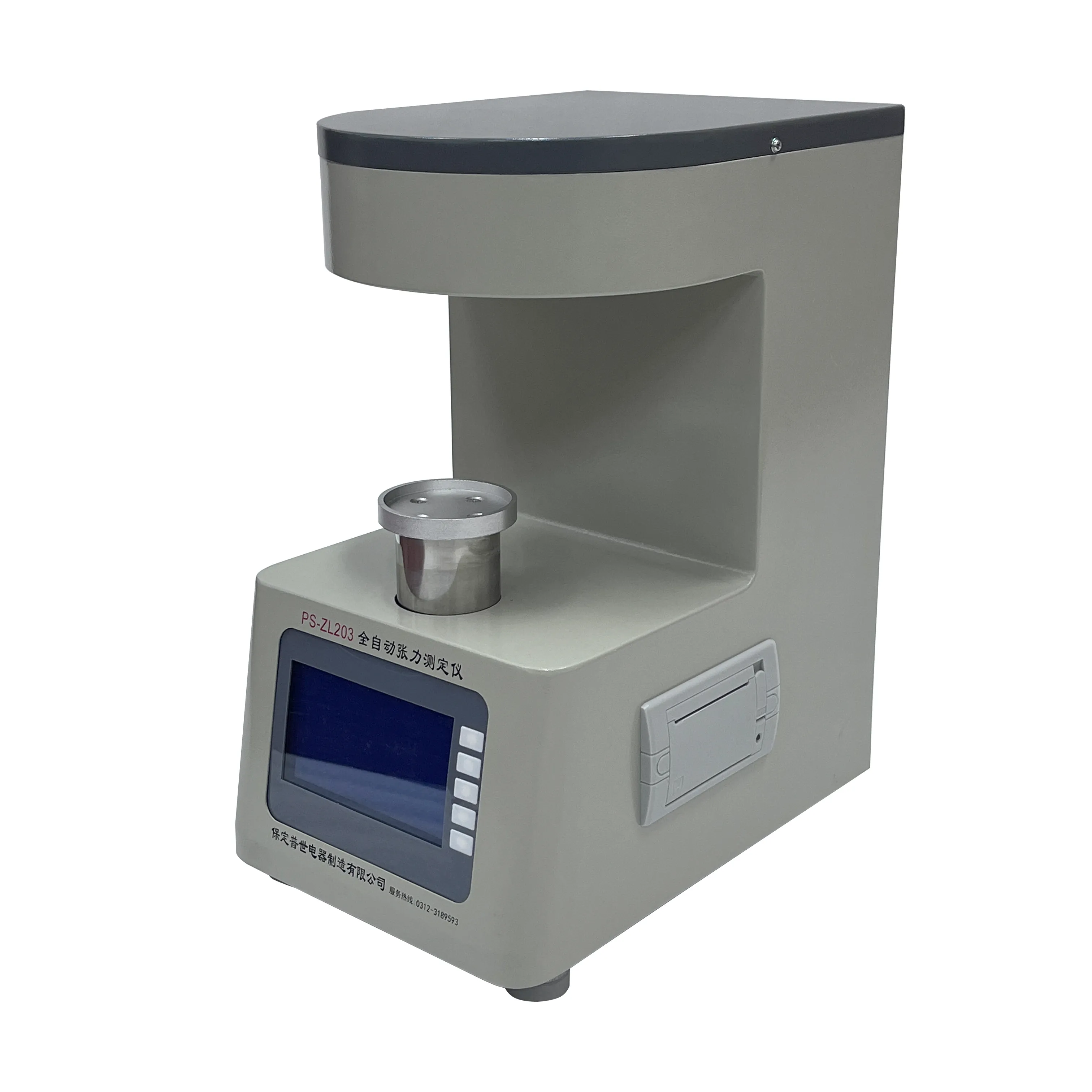

lube oil testing kit

Understanding Lube Oil Testing Kits Essential Tools for Maintenance

In the modern industrial landscape, machinery uptime and operational efficiency are critical to success. One of the key factors in achieving this is the effective management of lubricant systems. The quality of lube oil directly impacts the performance and longevity of machinery. To ensure that the lube oil used in engines, compressors, and other critical systems remains in optimal condition, many industries turn to lube oil testing kits.

What is a Lube Oil Testing Kit?

A lube oil testing kit is a comprehensive tool designed to analyze the condition of lubricating oils. These kits typically consist of various testing equipment and supplies that allow users to conduct on-site analyses of lubrication quality. They can measure crucial parameters that indicate oil health, such as viscosity, acidity (total acid number, TAN), particulate contamination, water content, and the presence of wear metals.

Importance of Lubrication Testing

Routine testing of lubrication systems is vital for several reasons. Firstly, it helps identify potential issues before they escalate into severe malfunctions. By detecting lubricant degradation or contamination early on, maintenance teams can take corrective measures, avoiding costly repairs and extended downtime.

Additionally, lube oil testing provides insights into the overall health of the machinery. The data obtained can be analyzed to assess wear patterns, enabling predictive maintenance strategies. This approach shifts maintenance from a reactive to a proactive model, allowing for better resource allocation and scheduling.

Key Components of a Lube Oil Testing Kit

1. Viscometer This instrument measures the viscosity of the oil, which is crucial for ensuring proper flow and lubrication under various operational conditions.

lube oil testing kit

2. Spectrometer Used to analyze the elemental composition of the oil, this device can detect the presence of wear metals, contaminants, and additives, providing valuable information about oil condition and equipment wear.

3. Water Activity Meter This tool helps determine the water content in the oil, as excess moisture can lead to rust, corrosion, and reduced lubricating properties.

4. TAN Tester A total acid number tester assesses the acidity of the oil, indicating oil degradation and the formation of harmful acids that can lead to corrosion and damage.

5. Filtering Equipment A particle counter or filter paper is often included to measure and categorize particulate contamination levels.

The Process of Oil Testing

Using a lube oil testing kit typically involves collecting oil samples directly from the machinery during routine maintenance checks. Once the samples are collected, they are analyzed using the various tools in the kit. The results give maintenance personnel a clear picture of the oil's current condition.

Conclusion

In conclusion, lube oil testing kits are invaluable assets in industrial maintenance strategy. They empower businesses to monitor lubricating oil conditions continuously, ensuring that machinery operates efficiently and reliably. By integrating these testing kits into regular maintenance routines, companies can extend the life of their equipment, reduce operational costs, and enhance productivity. In a world where every minute counts, proactive management of lube oil quality can make all the difference in maintaining operational excellence.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024