English

English

oil dielectric strength test

Oil Dielectric Strength Test Importance and Methodology

The oil dielectric strength test is a crucial procedure used to evaluate the electrical insulation properties of oil, particularly in electrical equipment such as transformers and capacitors. Dielectric strength refers to the maximum voltage an insulating material can withstand without breaking down, which is essential for ensuring the reliability and safety of electrical systems.

In the context of insulating oils, dielectric strength testing helps determine how well the oil can act as an insulator under high voltage conditions

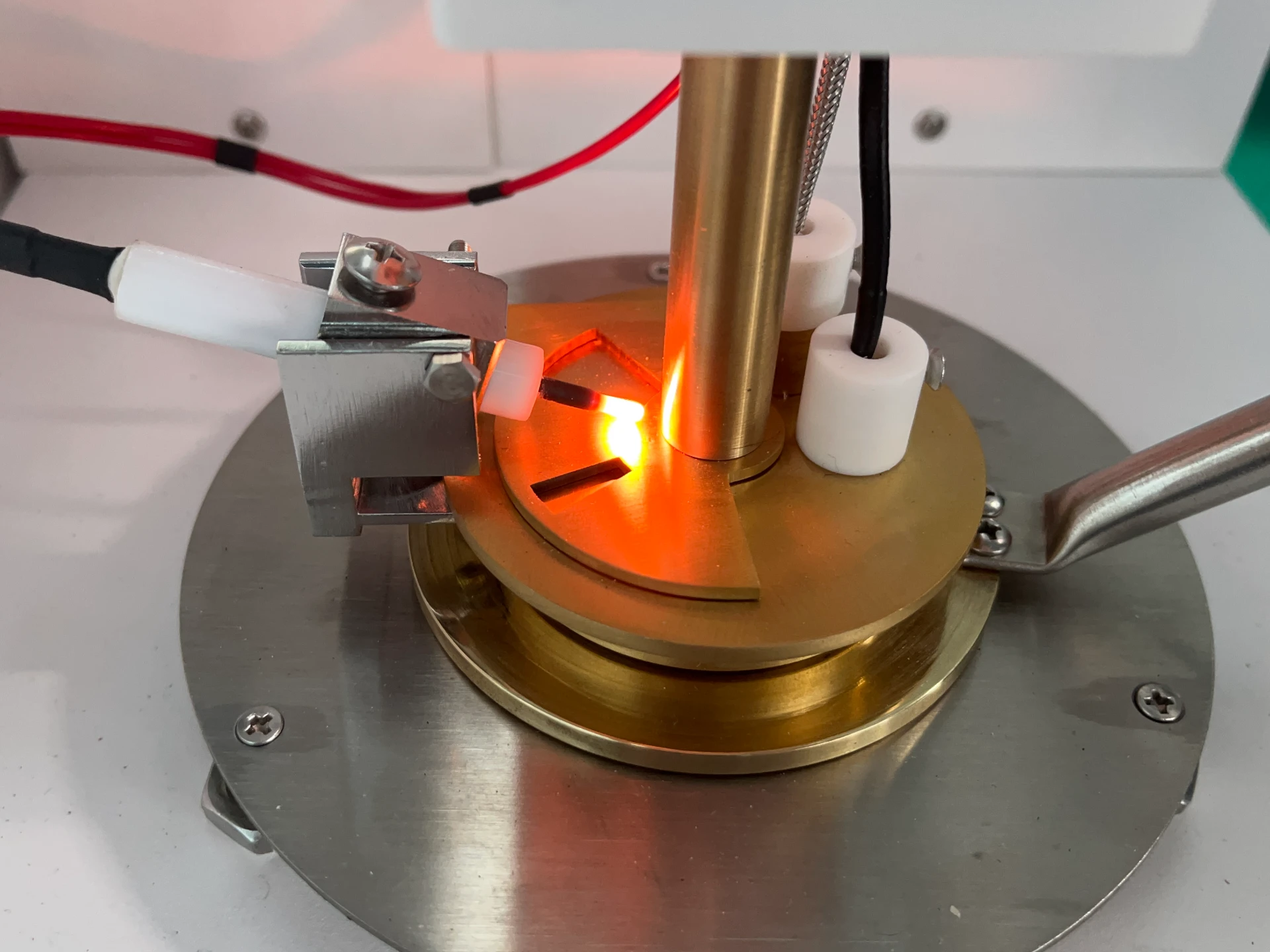

. A decrease in dielectric strength may indicate contamination, degradation, or the presence of moisture, all of which can compromise the performance of electrical apparatus.The testing process typically follows standardized procedures set by organizations such as ASTM (American Society for Testing and Materials) or IEC (International Electrotechnical Commission). The most common method employed is the cup or electrode test, where a sample of the oil is placed between two electrodes. The setup is designed to prevent leakage currents and ensure accurate readings.

oil dielectric strength test

During the test, voltage is gradually applied to the oil sample until a dielectric breakdown occurs, resulting in a short circuit between the electrodes. The voltage level at which this breakdown occurs is recorded as the dielectric strength of the oil. This value is usually expressed in kilovolts per millimeter (kV/mm) and is an essential indicator of the oil's insulating properties.

Several factors can influence the dielectric strength of insulating oil, including temperature, contamination levels, and the oil's chemical composition. Hence, it’s vital to control these variables during testing to achieve reliable results. Regular testing of insulating oils is recommended, particularly in equipment subjected to harsh conditions or those that have been in service for an extended period.

Failure to monitor dielectric strength can lead to catastrophic equipment failures, disrupting operations and incurring substantial repair costs. Additionally, poor dielectric strength can increase the risk of electrical accidents, posing safety hazards to personnel and the environment.

In conclusion, the oil dielectric strength test is an invaluable tool in electrical engineering, ensuring the integrity and longevity of vital equipment. By adhering to established testing standards and conducting regular assessments, engineers can maintain optimal performance and safety of electrical systems, ultimately contributing to a more reliable power supply.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024