English

English

oil compression tester

Understanding Oil Compression Testers

Oil compression testers are vital tools in the automotive and mechanical industries, used to assess the condition of an engine's compression system. These devices measure the pressure inside the engine cylinders, which is crucial for determining the performance and efficiency of an engine. Understanding how these testers work and their significance can aid in diagnosing engine problems early, thus saving time and money on repairs.

At its core, an oil compression tester operates by inserting a gauge into the spark plug hole of an engine cylinder. When the engine is cranked, the tester measures the maximum pressure generated during the compression stroke. A properly functioning engine will typically show consistent pressure across all cylinders, whereas significant discrepancies may indicate potential issues such as worn piston rings, damaged cylinder walls, or leaks.

One of the key advantages of using an oil compression tester is its ability to provide immediate feedback on engine health. Mechanics often recommend performing a compression test as part of routine maintenance or when diagnosing specific engine issues, such as excessive oil consumption, poor fuel efficiency, or reduced power output. By identifying weak cylinders or abnormal pressure readings, technicians can take appropriate measures to rectify these problems before they lead to more severe engine damage.

oil compression tester

In addition to identifying existing issues, oil compression testers can also help predict future engine performance. For instance, a gradual decline in compression readings over time might indicate that an engine is nearing the end of its life cycle. This information can be invaluable for fleet management, allowing for better planning of maintenance schedules and budgeting for potential engine replacements.

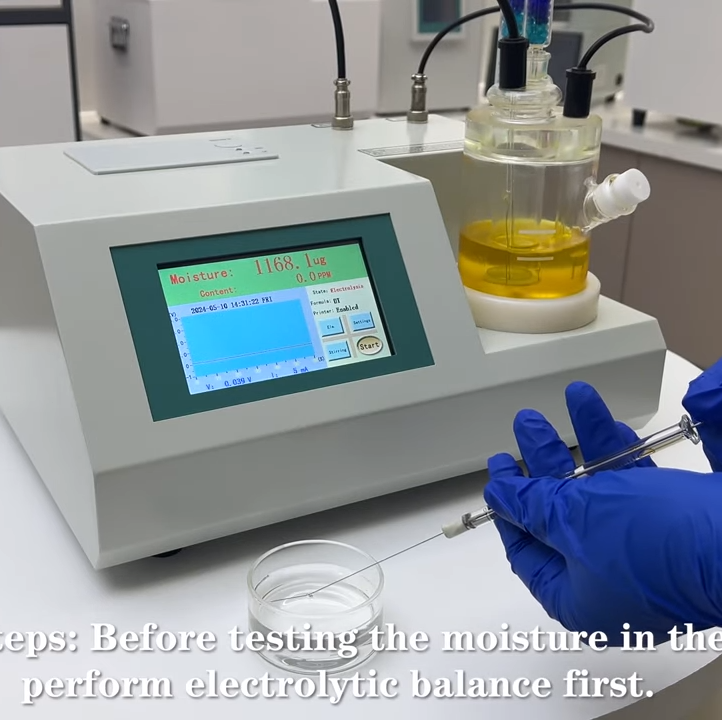

When using an oil compression tester, it is important to follow specific steps to ensure accurate readings. After removing the spark plug, the tester is inserted securely, and the engine is cranked several times to obtain a maximum reading. Mechanics typically take readings from each cylinder and compare them to the manufacturer's specifications. It is advisable to perform the test when the engine is warm for more reliable results, as cold engines can sometimes yield misleading data.

In conclusion, oil compression testers are essential instruments for anyone working with internal combustion engines. They provide critical information about engine performance and longevity, enabling proactive maintenance and repair actions. Understanding how to effectively use these tools is crucial for anyone involved in automotive repair or engine diagnostics. By leveraging the insights gained from compression testing, operators can enhance engine reliability, efficiency, and overall vehicle performance.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024