TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

1 月 . 15, 2025 09:11

Back to list

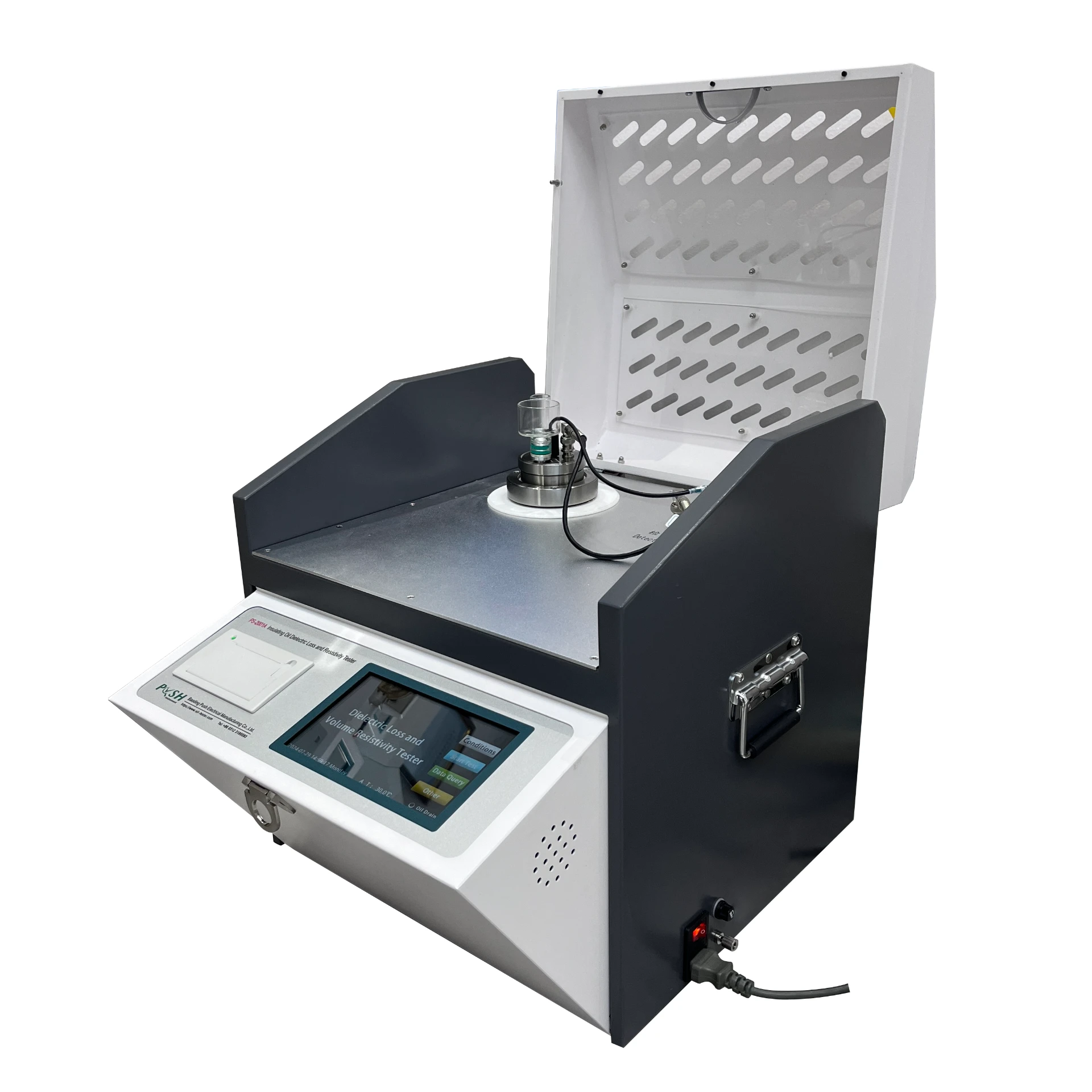

oil dielectric tester

Oil dielectric testers are imperative tools for professionals in the electrical and mechanical engineering industries. Their significance is underscored by the meticulous testing of transformer oils, ensuring the efficient operation and longevity of transformers. As we delve into the sophisticated realm of oil dielectric testers, it's vital to encompass experience, expertise, authoritativeness, and trustworthiness.

Trustworthiness is derived from consistent performance and positive user feedback. Product reviews and case studies contribute significantly, illustrating scenarios where oil dielectric testers have safeguarded infrastructure investments. For instance, a case study in a leading engineering journal detailed how a utility provider employed a specific model for annual testing, successfully extending transformer lifespan by up to 30%. Such documented reliability bolsters confidence among prospective users and reinforces trust in product effectiveness. When selecting an oil dielectric tester, consider factors like test range, accuracy, ease of use, and after-sales support, all vital for ensuring a sound investment. Manufacturers that offer comprehensive training and responsive customer service often enjoy higher trust ratings. This holistic approach, incorporating technical prowess and customer interaction, cements the tester's role as an indispensable asset in the industry. In conclusion, oil dielectric testers stand as pillars of preventive maintenance and operational safety. Aligning with recognized standards, supported by user testimonials, and validated by industry specialists, these instruments embody quintessential expertise, authority, and trustworthiness. As infrastructure continues to evolve, the integral role of reliable oil dielectric testing in safeguarding electrical assets remains undeniable.

Trustworthiness is derived from consistent performance and positive user feedback. Product reviews and case studies contribute significantly, illustrating scenarios where oil dielectric testers have safeguarded infrastructure investments. For instance, a case study in a leading engineering journal detailed how a utility provider employed a specific model for annual testing, successfully extending transformer lifespan by up to 30%. Such documented reliability bolsters confidence among prospective users and reinforces trust in product effectiveness. When selecting an oil dielectric tester, consider factors like test range, accuracy, ease of use, and after-sales support, all vital for ensuring a sound investment. Manufacturers that offer comprehensive training and responsive customer service often enjoy higher trust ratings. This holistic approach, incorporating technical prowess and customer interaction, cements the tester's role as an indispensable asset in the industry. In conclusion, oil dielectric testers stand as pillars of preventive maintenance and operational safety. Aligning with recognized standards, supported by user testimonials, and validated by industry specialists, these instruments embody quintessential expertise, authority, and trustworthiness. As infrastructure continues to evolve, the integral role of reliable oil dielectric testing in safeguarding electrical assets remains undeniable.

Previous:

Latest news

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024