English

English

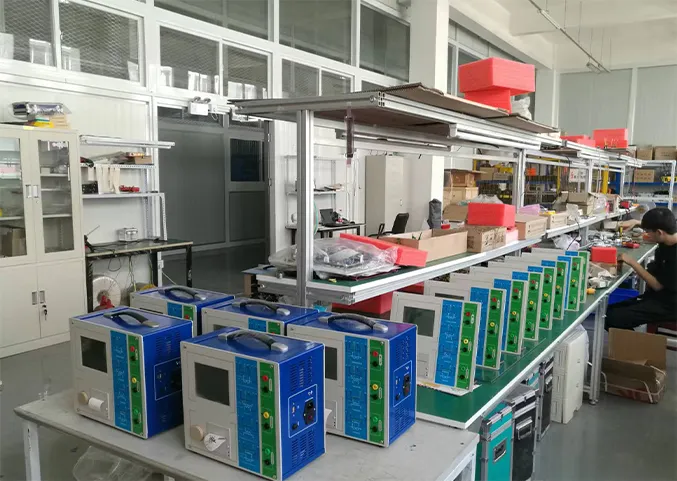

oil friction test machine

The Importance of Oil Friction Test Machines in Modern Engineering

In today’s rapidly advancing technological landscape, the effective evaluation of materials and their properties is essential for innovation and safety in various industries. One specific area that has garnered significant attention is the study of friction between surfaces, particularly in mechanical systems. A crucial instrument in this field is the oil friction test machine, which plays a pivotal role in assessing the lubrication properties of oils and their interaction with different materials under various conditions.

Understanding Oil Friction Testing

Oil friction test machines are designed to simulate real-life conditions in which lubricants operate. These machines generate precise measurements of frictional forces between moving surfaces while evaluating the performance of lubricating oils. Accurate testing is vital, as it allows engineers to determine how well a lubricant can reduce wear and tear on machinery, sustain operational efficiency, and prolong the life of mechanical components.

The heart of the testing process lies in creating a controlled environment where parameters such as temperature, speed, and load can be meticulously adjusted. By analyzing the results generated from these tests, engineers can gain valuable insights into how different oils perform under specific conditions, enabling them to make informed decisions regarding lubricants to use in particular applications.

Applications Across Industries

The significance of oil friction test machines extends across several industries, including automotive, aerospace, and manufacturing. In the automotive sector, for instance, the performance of engine oils can significantly impact fuel efficiency and engine longevity. By utilizing oil friction test machines, manufacturers can refine their products, ensuring they meet the rigorous demands of modern vehicles.

oil friction test machine

In aerospace, where high precision and reliability are critical, the ability to test lubricants under extreme conditions is invaluable. Oil friction test machines help assess how lubricants behave at high altitudes and temperatures, where mechanical failure can have catastrophic consequences. Similarly, in manufacturing, these machines help optimize machinery by ensuring that the appropriate lubricants are used to prevent breakdowns and maintain productivity.

Innovations and Technological Advancements

With the rise of advanced manufacturing techniques and materials, the need for sophisticated testing equipment has become increasingly necessary. Recent innovations in oil friction test machines have led to more automated systems capable of conducting tests with higher accuracy and repeatability. Advanced sensors and data acquisition systems allow for real-time monitoring of friction coefficients, temperature variations, and other critical metrics.

Moreover, the integration of software solutions has enabled engineers to analyze test results efficiently, offering simulations and predictive analyses that can guide decision-making processes. This synergy between hardware and software marks a significant leap forward in the realm of materials testing and development.

Conclusion

In conclusion, oil friction test machines are an indispensable tool in the quest for better-performing lubricants across various industries. Their ability to simulate real-world conditions and provide precise data on frictional properties empowers engineers to make informed choices that enhance product performance, sustainability, and safety. As technology continues to evolve, the role of these machines will undoubtedly grow, further cementing their place as crucial instruments in modern engineering practices. As industries strive for greater efficiency and reliability, oil friction test machines will remain at the forefront of innovation, ensuring that the materials we rely on are tested, optimized, and ready for the challenges of the future.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024