English

English

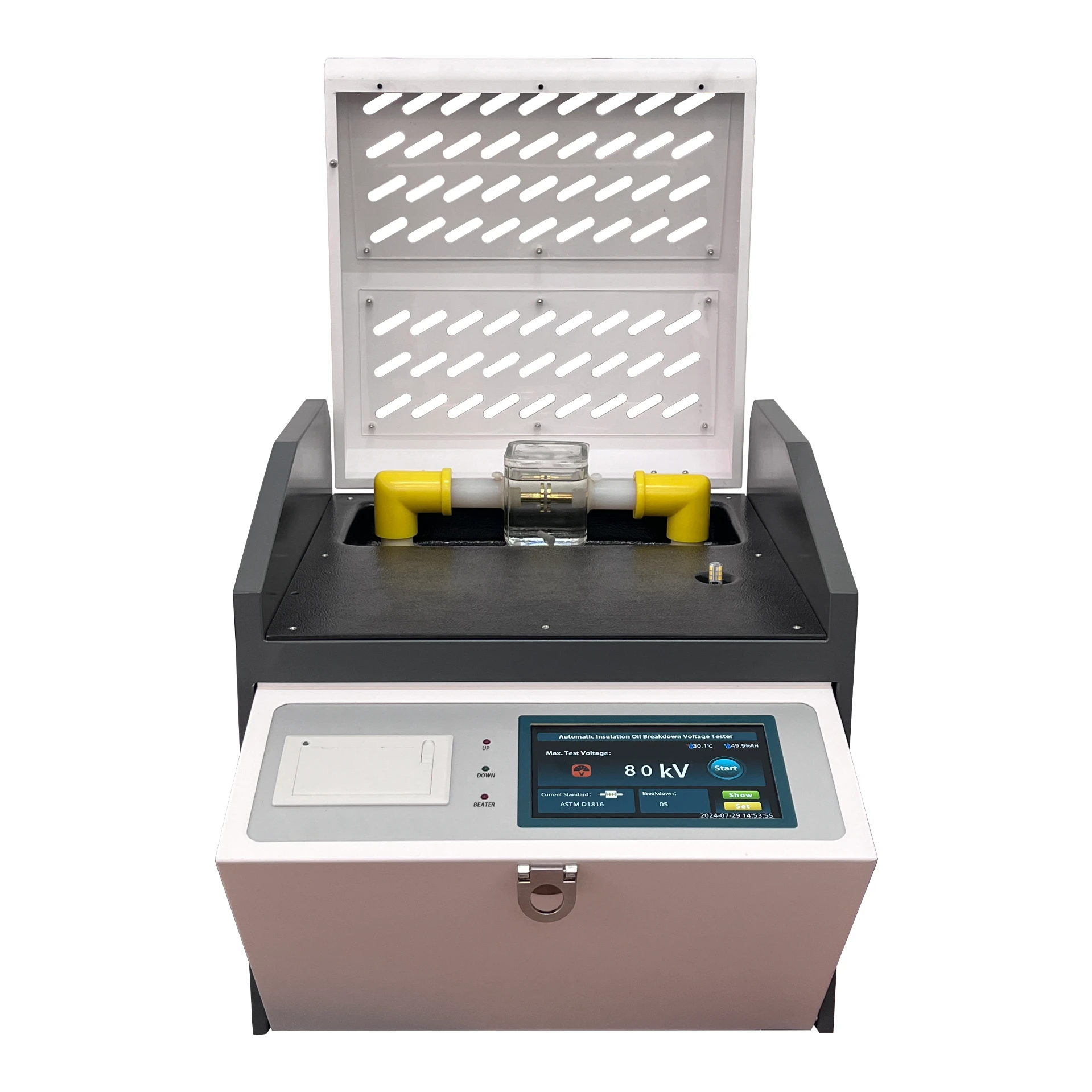

Premium Oil Test Equipment Reliable & Accurate Solutions

Exploring the realm of oil test equipment reveals a fascinating world driven by precision and innovation

. These tools play a critical role across diverse industries, adapting to rapidly evolving demands. Understanding oil test equipment is key to ensuring the efficiency and longevity of machinery, which is crucial for businesses ranging from automotive to industrial manufacturing.

Real-world experiences highlight the transformative impact of advanced oil testing on operational efficiency. For instance, a mid-sized manufacturing company in Ohio recently integrated state-of-the-art oil test equipment into their maintenance routine. This led to a 20% reduction in machine downtime and resulted in substantial cost savings. Such outcomes are not only impressive but underscore the essential role these tools play in proactive maintenance strategies.

The expertise required to navigate the selection and implementation of oil test equipment is substantial. The market offers a wide array of devices, such as viscometers, flash point testers, and spectrometers. Each serves a distinct purpose, and understanding their functions is vital. Viscometers measure the viscosity of oil, providing insight into its lubrication efficiency. Flash point testers determine the temperature at which oil vapors ignite, which is critical for safety assessments. Spectrometers analyze metal content in oil samples, revealing wear patterns and potential component failures. Mastery of these devices ensures accurate diagnostics and enhances decision-making processes.

Authoritativeness in the field of oil test equipment stems from decades of research and technological advancements. Renowned institutions and industry leaders continuously contribute to the development and refinement of testing methodologies. The American Society for Testing and Materials (ASTM), for instance, has established comprehensive standards that guide the manufacture and calibration of oil test equipment. Compliance with these standards ensures that the devices deliver reliable and reproducible results, thus reinforcing their credibility.

oil test equipment

Trustworthiness is non-negotiable when it comes to oil test equipment. Businesses rely on the data provided by these tools to make pivotal decisions regarding equipment maintenance and safety. Ensuring that the equipment is sourced from reputable manufacturers with proven track records is paramount. Regular calibration and maintenance are also crucial to preserve the integrity and accuracy of the data generated. Establishing partnerships with certified suppliers can further enhance trust, as they often offer robust after-sales support and training, helping users maximize the utility and lifespan of their equipment.

As the industry heads toward more sustainable practices, innovations in oil test equipment continue to emerge. Technologies such as real-time monitoring systems and data analytics are revolutionizing how oil conditions are assessed. These advancements enable businesses to implement predictive maintenance strategies, thereby optimizing resource allocation and reducing environmental impact. By staying abreast of these developments, companies can maintain a competitive edge while contributing to more sustainable industrial practices.

Investing in the right oil test equipment is not merely a purchase but a strategic decision that can yield significant long-term benefits. By leveraging expert knowledge, adhering to authoritative guidelines, and committing to trustworthy practices, businesses can enhance their operational resilience. As industries continue to evolve, the necessity for precise and reliable oil testing solutions will only grow, reinforcing their status as indispensable assets in modern manufacturing and maintenance landscapes.

-

Differences between open cup flash point tester and closed cup flash point testerNewsOct.31,2024

-

The Reliable Load Tap ChangerNewsOct.23,2024

-

The Essential Guide to Hipot TestersNewsOct.23,2024

-

The Digital Insulation TesterNewsOct.23,2024

-

The Best Earth Loop Impedance Tester for SaleNewsOct.23,2024

-

Tan Delta Tester--The Essential Tool for Electrical Insulation TestingNewsOct.23,2024